Abstract

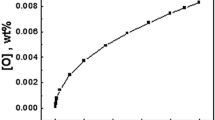

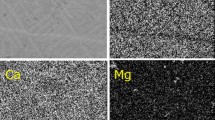

Experiments were carried out to determine the effect of Al2O3 in the slag of the CaO-SiO2-Al2O3-MgO-CaF2 system on the cleanness of Fe-13Cr stainless steel deoxidized by ferrosilicon. Increasing the Al2O3 content in basicity = 2.28 slag can reduce the usage of CaF2 and benefit the obtainment of a good kinetic condition for inclusion removal, but over 21 pct would lead to a higher total oxygen content in the melt and make the inclusion composition more complex. It is found that increasing basicity in 16 pct Al2O3 slag would have a good deoxidation ability and accelerate the transformation from high Al2O3 inclusions to low melting point CaO-Al2O3-SiO2-MgO system inclusions, but basicity over 2.58 would lead to high content of [Al] in liquid steel, which would promote the formation of MgO-Al2O3 inclusions. Therefore, it is not suitable to add a high content of Al2O3 into high-basicity slag. Adding Al2O3 into slag of 2.28 in basicity until a content of 16 pct could achieve inclusion plastication within 45 minutes without Ca treatment, which has potential application in industrial production.

Similar content being viewed by others

References

T. Fujisawa, M. Suzuki, Y. Wanibe, and H. Sakao: Tetsu-to-Hagané, 1986, vol. 72, pp. 218–24.

K. Suzuki, S. Banya, and M. Hino: ISIJ Int., 2001, vol. 41, pp. 813–17.

P. Yan, S. Huang, L. Pandelaers, J. Vandyck, M. Guo, and B. Blanpain: Metall. Mater. Trans. B, 2013, vol. 44B, pp. 1105–19.

W. Yang, X. Wang, L. Zhang, Q. Shan, and X. Liu: Steel Res. Int., 2013, vol. 84, pp. 473–89.

H. Suito and R. Inoue: ISIJ Int., 1996, vol. 36, pp. 528–36.

P.K. Iwamasa and R.J. Fruehan: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 47–57.

K. Mizuno, H. Todoroki, M. Noda, and T. Tohge: Iron Steelmaker, 2001, vol. 28, 93–101.

J.W. Kim, S.K. Kim, D.S. Kim, Y.D. Lee, and P.K. Yang: ISIJ Int., 1996, vol. 36, pp. S140–S143.

K. Sakata: ISIJ Int., 2006, vol. 46, pp. 1795–99.

Y. Ehara, S. Yokoyama, and M. Kawakami: Tetsu-to-Hagané, 2007, vol. 93, pp. 475–82.

Steelmaking Data Sourcebook, The Japan Society for the Promotion of Science, The 19th Committee on Steelmaking, Goldon Breach Science, New York, 1988.

M.P. Howard and B. Debanshu: Metall. Mater. Trans. B, 1984, vol. 15B, pp. 547–62.

H. Itoh and M. Hino: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 953–56.

H. Ohta and H. Suito: ISIJ Int., 2003, vol. 43, pp. 1293–1300.

M.H. Zayan, O.M. Jamjoom, and N.A. Razik: Oxide Metall., 1990, vol. 34, pp. 323–33.

G. Okuyama, K. Yamaguchi, S. Takeuchi, and K. Sorimachi: ISIJ Int., 2000, vol. 40, pp. 121–28.

D. Kim and J.H. Park: Metall. Mater. Trans. B, 2012, vol. 43B, pp. 875–86.

J.H. Park: Metall. Mater. Trans. B, 2007, vol. 38B, pp. 657–63.

Acknowledgments

The authors express their appreciation to the National Nature Science Foundation of China (Grant Nos. 51104013, 51174022, and 51374020), the Fundamental Research Funds for the Central Universities (Grant No. FRF-TP-15-052A3), the Beijing Higher Education Young Elite Teacher Project (Grant No. YETP0349), and the China Postdoctoral Science Foundation (Grant No. 2014M560046).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 7, 2016.

Rights and permissions

About this article

Cite this article

Wang, Q., Wang, L., Zhai, J. et al. Evolution of Inclusions in Fe-13Cr Treated by CaO-SiO2-Al2O3-Based Top Slag. Metall Mater Trans B 48, 564–572 (2017). https://doi.org/10.1007/s11663-016-0852-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0852-1