Abstract

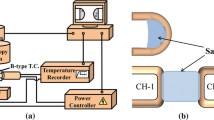

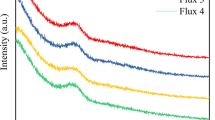

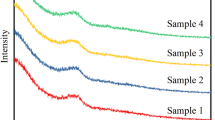

This paper investigated the effects of CaO/SiO2 ratio (0.8 to 1.5) and Na2O concentration (6 to 9 wt pct) on melting properties and viscosity of SiO2-CaO-Al2O3-B2O3-Na2O mold fluxes with a fixed B2O3 content. Melting properties of fluxes (softening temperature T s, hemispherical temperature T h, and fluidity temperature T f) were determined by the hot-stage microscopy method. Viscosity was measured using rotating cylindrical viscometer, and structure of quenched fluxes was studied using Raman spectroscopy. Equilibrium phases in the SiO2-CaO-Al2O3-B2O3-Na2O system were calculated using FactSage. It was found that T h decreased with increasing CaO/SiO2 ratio from 0.8 to 1.0 and increased with a further increase in the CaO/SiO2 ratio to 1.5. The effect of Na2O content in the range of 6 to 9 wt pct on T h of the flux with a fixed CaO/SiO2 ratio at 1.3 was marginal. Increasing CaO/SiO2 ratio and Na2O content increased the break temperature and reduced the value of viscosity at 1673 K (1400 °C). Viscosity of liquid fluxes was discussed in the relationship with the flux structure. Melting properties and viscosity of boracic fluxes were compared with those of industrial fluorine-containing mold fluxes.

Similar content being viewed by others

References

1. C.A.M. Pinheiro, I.V. Samarasekera, J.K. Brimacombe, and B.N. Walker: Ironmak. Steelmak., 2000, vol. 27, pp. 37–54.

2. K.C. Mills and A.B. Fox: ISIJ Int, 2003, vol. 43, pp. 1479–86.

3. E. Benavidez, L. Santini, M. Valentini, and E. Brandaleze: Proc. Mater. Sci., 2012, vol. 1, pp. 389–96.

M. Srinivasan: Science and Technology of Casting Processes, 1st ed., InTech, Chennai, 2012, pp. 205–33.

5. A.B. Fox, K.C. Mills, D. Lever, C. Bezerra, C. Valadares, I. Unamuno, J.J. Laraudogoitia, and J. Gisby: ISIJ Int., 2005, vol. 45, pp. 1051–58.

J. Moore, R. Phillips, and T. Gibbs, Steelmak. Conf. Proc., 1991, pp. 615–21.

M. Kawamoto, K. Nakajima, T. Kanazawa, and K. Nakai: Steelmak. Conf. Proc., 1992, pp. 389–96.

8. B.G. Thomas: Metall. Mater. Trans. B., 2002, vol. 33, pp. 795–12.

9. T. Matsushita, M. Hayashi, and S. Seetharaman: Int. J. Mater Prod. Tec., 2005, vol. 22, pp. 351–90.

10. L.J. Zhou, W.L. Wang, J. Wei, and B.X. Lu, ISIJ Int., 2013, vol. 53, pp. 665–72.

11. Z.T. Zhang, G.H. Wen, and Y.Y. Zhang, Int. J. Min. Met. Mater., 2011, vol. 18, pp. 150–58.

12. S.Y. Choi, D.H. Lee, D.W. Shin, S.Y. Choi, J.W. Cho, and J.M. Park: J. Non-Cryst. Solids, 2004, vol. 345, pp. 157–60.

13. Z. Wang, Q.F. Shu, and K.C. Chou: Steel. Res. Int., 2013, vol. 84, pp. 766–76.

14. G.H. Wen, S. Sridhar, P. Tang, X. Qi, and Y.Q. Liu, ISIJ Int., 2007, vol. 47, pp. 1117–25.

15. H.M. Wang, P.S. Li, G.R. Li, M. Zhang, Z. Zhao, and Y. Zhao: Appl. Mech. Mater., 2012, vol. 217, pp. 35–38.

16. L. Wang, Y. Cui, J. Yang, C. Zhang, D. Cai, J. Zhang, Y. Sasaki, and O. Ostrovski: Steel. Res. Int., 2015, vol. 86, pp. 670–77.

17. M. Persson, M. Görnerup, and S. Seetharaman: ISIJ Int., 2007, vol. 47, pp. 1533–40.

18. K.C. Mills: Slag Atlas, 2nd ed., Verlag Stahleisen GmbH, Düsseldorf, 1995, pp. 349–99.

19. X.J. Dong, H.Y. Sun, X.F. She, Q.G. Xue, and J.S. Wang: Ironmak. Steelmak., 2013, vol. 41, pp. 99–106.

20. S. Ogibayashi, K. Yamaguchi, T. Mukai, T. Takahashi, Y. Mimura, K. Koyama, Y. Nagano, and T. Nakano, Nippon Steel Technical Report. Overseas, 1987, vol. 34, pp. 1–10.

21. N. Takahira, M. Hanao, and Y. Tsukaguchi: ISIJ Int., 2013, vol. 53, pp. 818–22.

22. J.L. Klug, R. Hagemann, N.C. Heck, A.C.F. Vilela, H. P. Heller, and P. R. Scheller: Steel. Res. Int., 2012, vol. 83, pp. 1186–93.

23. J.F. Xu, J.Y. Zhang, C. Jie, L. Tang, and K. C. Chou: Adv. Mat. Res., 2011, vol. 194–196, pp. 169–74.

24. S. Sridhar, K. Mills, O. Afrange, H. Lörz, and R. Carli: Ironmak. Steelmak., 2000, vol. 27, pp. 238–42.

25. S. Arrhenius: Biochem. J., 1917, vol. 11, pp. 112–33.

26. A. Cruz, F. Chavez, A. Romero, E. Palacios, and V. Arredondo: J. Mater Process. Tech., 2007, vol. 182, pp. 358–62.

J. Kromhout: Ph.D. Dissertation, Delft University of Technology, Delft, 2006.

28. J. Cho, H. Shibata, T. Emi, and M. Suzuki: ISIJ Int., 1998, vol. 38, pp. 268–75.

29. J.W. Cho, T. Emi, H. Shibata, and M. Suzuki, ISIJ Int., 1998, vol. 38, pp. 834–42.

30. J. Romo-Castaneda, A. Cruz-Ramirez, A. Romero-Serrano, M. Vargas-Ramirez, and M. Hallen-Lopez: Thermochim. Acta., 2011, vol. 512, pp. 129–33.

31. S.P. He, Q.Y. Huang, G.X. Zhang, Y.J. Lu, and Q. Wang: J. Iron Steel. Res. Int., 2011, vol. 18, pp. 15–19.

32. L. Zhou, W. Wang, B. Lu, G. Wen, and J. Yang: Metals Mater. Inter., 2015, vol. 21, pp. 126–33.

33. L. Zhou, W. Wang, and K. Zhou: ISIJ Int., 2015, vol. 55, pp. 1916–24.

Z. Elahipanah: M.Sc. Dissertation, Royal Institute of Technology, Stockholm, 2012.

35. G.H. Zhang, K.C. Chou, and K. Mills: Metall. Mater. Trans. B, 2013, vol. 45, pp. 698–706.

36. K.C. Mills: ISIJ Int., 1993, vol. 33, pp. 148–55.

37. B. Mysen and P. Richet: Silicate Glasses and Melts: Properties and Structure, 1st ed., Elsevier, Amsterdam, AE, 2005, pp. 207–208.

38. T. Furukawa, K. E. Fox, and W.B. White: J. Chem. Phys., 1981, vol. 75, pp. 3226–37.

39. Y. Iguchi, S. Kashio, T. Goto, Y. Nishina, and T. Fuwa: Can. Metall. Q., 1981, vol. 20, pp. 51–56.

40. J. Kline, M. Tangstad, and G. Tranell: Metall. Mater Trans. B, 2015, vol. 46, pp. 62–73.

41. B.O. Mysen, D. Virgo, and F.A. Seifert: Rev. Geophys., 1982, vol. 20, pp. 353–83.

42. J.H. Park: ISIJ Int., 2012, vol. 52, pp. 1627–36.

43. B. Mysen: Eur. J. Mineral, 2003, vol. 15, pp. 781–702.

44. I. Sohn and D.J. Min: Steel. Res. Int., 2012, vol. 83, pp. 611–30.

Acknowledgments

This project was financially supported by Baosteel through BAJC, Abel Metal, and Australian Research Council (ARC LP130100773).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 29, 2016.

Rights and permissions

About this article

Cite this article

Wang, L., Zhang, C., Cai, D. et al. Effects of CaO/SiO2 Ratio and Na2O Content on Melting Properties and Viscosity of SiO2-CaO-Al2O3-B2O3-Na2O Mold Fluxes. Metall Mater Trans B 48, 516–526 (2017). https://doi.org/10.1007/s11663-016-0816-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-016-0816-5