Abstract

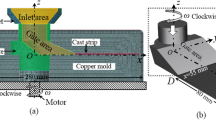

The flow of molten metal plays a crucial role in determining casting quality. During rotation of the mold, melt flow around its inner circumference determines the final configurations and properties of the cast tube. In this paper, Al-2Si alloy is cast in the vertical mold at the various rotational speeds of the mold. The uniform cylinder tube is formed at a rotational speed of 1000 rpm, while before and beyond this speed, irregular-shaped cast tube is formed. Finally, fine structured grain size with high hardness value is found in uniform cast tube compared with others.

Similar content being viewed by others

References

N. Janco: Centrifugal Casting, American Foundrymen’s Society (1988).

Y. Jaluria: J. Fluid. Eng.-T. ASME, 2001, vol. 123, pp. 173–210.

A. Shailesh Rao, P.G. Mukunda, and S. Shrikantha Rao: AFI/TFI-2007. Commemoration of the 100th Anniversary of Tohoku University, Sendai, Miyagi, Japan (2007).

A. Shailesh Rao, P.G. Mukunda, and S. Shrikantha Rao, J. Fluid. Mech. Vol. 2, (2009), pp. 39-44.

A. Shailesh Rao, P.G. Mukunda, and S. Shrikantha Rao, Met. Mater. Int., Vol. 16, No. 1, pp. 137-143 2010.

W.S. Ping, L.D. Rong, G.J. Jie, L.C. Yun, and S.Y. Qing, Mater.Sci. Eng. A 426, 240 (2006).

S.R. Chang: ISIJ Int., 2001, vol. 41 (7), pp 738–747.

C. Li, H. Wang, S. Wu, L. Xu, K. Wang, and H. Fu: Rare Metal Materials and Engineering, 2010, vol. 39 (3), pp. 388-392.

S.M.H. Mirbagheri, M. Dadashzadeh, S. Serajzadeh, A.K. Taheri, and P. Davami: Appl. Math. Model., 2004, vol. 28, pp 933–956.

S.M.H. Mirbagheri, M. Shrinparvar, H. Ashory, and P. Davami: Materials and Design, 2004, vol. 25, pp 655–661.

G. Chirita, D. Soares, and F.S. Silva: Materials and Design, 2008, vol. 29, pp 20–27.

G. Chirita, I. Stefanescu, D. Cruz, D. Soares, and F.S. Silva: Materials and Design, 2010, vol. 31 (6), pp 2867-2877.

T. Rzychon: J. Achiev. Mater. Manuf. Eng., 2008, vol. 26 (2).

Jabbari M.: Mater. Sci. Eng. A, Vol. 528, No. 2, (2010), pp. 583-588.

WU Shi-ping, Trans. Nonferrous Met. SOCC. China 16 (2006), 1035-1040.

Suyitno, Materials Science and Engineering A 420 (2006) 1–7.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 9, 2014.

Rights and permissions

About this article

Cite this article

Shailesh Rao, A., Tattimani, M.S. & Rao, S.S. Effect of Rotational Speeds on the Cast Tube During Vertical Centrifugal Casting Process on Appearance, Microstructure, and Hardness Behavior for Al-2Si Alloy. Metall Mater Trans B 46, 793–799 (2015). https://doi.org/10.1007/s11663-014-0257-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-014-0257-y