Abstract

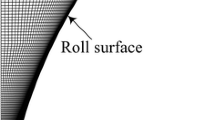

The modeling and controlling of flow and solidification of melt metal in the filling process is important for obtaining the optimal pool level and the formation of the solidified metal layer on the surface of twin-rolls during the twin-roll strip casting. The proper delivery system and processing parameters plays a key role to control flow characteristics in the initial filling stage of the twin-roll strip casting process. In this paper, a commercial CFD software was employed to simulate the transient fluid flow, heat transfer, and solidifications behaviors during the pouring stage of twin-roll strip casting process using different delivery systems. A 3D model was set up to solve the coupled set of governing differential equations for mass, momentum, and energy balance. The transient free-surface problem was treated with the volume of fluid approach, a k–ɛ turbulence model was employed to handle the turbulence effect and an enthalpy method was used to predict phase change during solidification. The predicted results showed that a wedge-shaped delivery system might have a beneficial impact on the distribution of molten steel and solidification. The predicted surface profile agreed well with the measured values in water model.

Similar content being viewed by others

References

N. Zapuskalov: ISIJ Int, 2003, vol. 43 (8), pp. 1115-27.

D. Raabe, R. Degenhardt, R. Sellger, W. Klos, M. Sachtleber, L. Ernenputsch: Steel Res. Int., 2008, vol. 79 (6), pp. 440-44.

R. Cook, P. G. Grocock, P. M. Thomas: J. Mater. Process. Tech., 1995, vol. 55, pp. 76-80.

A. R. Buchner: Steel Res. Int., 2004, vol. 75 (1), pp. 5-12.

K. Shibuya, M. Ozawa: ISIJ Int., 1991, vol. 31 (7), pp. 661-68.

S. Tanaka, I. Suichi, S. Ogawa: Steelmaking Conference Proc., Washington, 1991, vol. 74, pp. 809–16.

R. P. Tavares, R. I. L. Guthrie: Can. Metall. Q., 1998, vol. 37 (3-4), pp. 241-50.

R. I. L. Guthrie, R. P. Tavares: Appl. Math. Model., 1998, vol. 22, pp. 851-72.

J. D. Hwang, H. J. Lin, W. S. Hwang, C. T. Hu: ISIJ Int., 1995, vol. 35 (2), pp. 170-77.

J. D. Hwang, H. J. Lin, J. S. C. Jang, W. S. Hwang, C. T. Hu: ISIJ Int., 1996, vol. 36(6), pp. 690-99.

B. Wang, J. -Y. Zhang, Y. Zhang, J.-F. Fan, Y. Fang, S.-L. An: Ironmaking & steelmaking, 2008, vol. 35(1), pp. 75-80.

Bo Wang, Jieyu Zhang, Weidong Zhang, Sanbing Ren, Junfei Fan, Shengli An, K.-C. Chou: Steel Res. Int., 2011, vol. 82(7), pp. 819–26.

K. Miyazawa, J. Szekely: Metall. Trans. A, 1981, vol. 12A (6), pp. 1047-57.

A. R. Buechner: Steel Res. Int., 2006, vol. 77 (11), pp. 809-17.

J. W. Bae, C. G. Kang, S. B. Kang: J. Mater. Process. Tech., 2007, vol. 191, pp. 251-55.

C. A. Santos, J. A. Spim, A. Garcia: J. Mater. Process. Tech., 2000, vol. 102, pp. 33-39.

S. H. Seyedein, M. Hasan: Can. Metall. Q., 1998, vol. 37 (3-4), pp. 213-28.

Woo-seung Kim, Deok-soo Kim, A. V. Kuznetsov: Int. J. Heat Mass Transf., 2000, vol. 43, pp. 3811–22.

X. M. Zhang, Z. Y. Jiang, L. M. Yang, X. H. Liu, G. D. Wang, A. K. Tieu: Journal of Materials Processing Technology, 2007, vol. 187–188, pp. 339–43.

Z. Y. Liu, W. D. Zhang, B. Wang, G. X. Wu, F. Ruan, C. T. Liu, J. Y. Zhang: Ironmaking & Steelmaking, 2012, vol. 39(8), pp. 614-21.

Acknowledgments

The authors gratefully acknowledge the financial support received from the Innovative Foundation of Shanghai University (SDCX2013031).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 10, 2013.

Rights and permissions

About this article

Cite this article

Liu, Z., Wang, B., Zhang, Q. et al. Numerical Simulation of Filling Process During Twin-Roll Strip Casting. Metall Mater Trans B 45, 262–271 (2014). https://doi.org/10.1007/s11663-013-0012-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-013-0012-9