Abstract

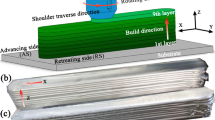

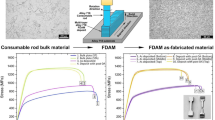

Friction Freeform Fabrication is a new solid-state additive manufacturing process. The present investigation reports a detailed study on the prospects of this process for additive part fabrication in superalloy Inconel 718. Using a rotary friction welding machine and employing alloy 718 consumable rods in solution treated condition, cylindrical-shaped multi-layer friction deposits (10 mm diameter) were successfully produced. In the as-deposited condition, the deposits showed very fine grain size with no grain boundary δ phase. The deposits responded well to direct aging and showed satisfactory room-temperature tensile properties. However, their stress rupture performance was unsatisfactory because of their layered microstructure with very fine grain size and no grain boundary δ phase. The problem was overcome by heat treating the deposits first at 1353 K (1080 °C) (for increasing the grain size) and then at 1223 K (950 °C) (for precipitating the δ phase). Overall, the current study shows that Friction Freeform Fabrication is a very useful process for additive part fabrication in alloy 718.

Similar content being viewed by others

References

I. Gibson, D.W. Rosen, and B. Stucker: Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing, Springer, New York, USA, 2010.

W. Chen and M. C. Chaturvedi: Acta Mater., 1997, vol. 45, pp. 2735-46.

S. Azadian, L.Y. Wei, and R. Wareen: Mater. Charact., 2004, vol. 53, pp. 7-16.

C. Slama and M. Abdellaoui: J. Alloys Compd., 2000, vol. 306, pp. 277-84.

S. Kou: Welding Metallurgy, 2nd edition, John Wiley & Sons, Inc. New Jersey, USA, 2003.

G.D. JanakiRam, A. VenugopalReddy, K. PrasadRao, and G. MadhusudhanReddy: Sci. Technol. Weld. Join., 2004, vol. 9, pp. 390–98.

J.C. Lippold, S.D. Kiser, and J.N. DuPont: Welding Metallurgy and Weldability of Nickel-Base Alloys, John Wiley & Sons, New Jersey, USA, 2009.

D. Clark, M.R. Bache, and M.T. Whittaker: J. Mater. Process. Technol., 2008, vol. 203, pp. 439-48.

X. Zhao, J. Chen, X. Lin, and W. Huang: Mater. Sci. Eng. A, 2008, vol. 478, pp. 119-24.

Q. Zhang, J. Yao, and J. Mazumder: J. Iron Steel Res. Int., 2011, vol. 18, pp. 73-8.

Z. Wang, K. Guan, M. Gao, X. Li, X. Chen, and X. Zeng: J. Alloys Compd., 2012, vol. 513, pp. 518-23.

F. Liu, X. Lin, H. Leng, J. Cao, Q. Liu, C. Huang, and W. Huang: Opt. Laser Technol., 2013, vol. 45, pp. 330-35.

P.L. Blackwell: J. Mater. Process. Technol., 2005, vol. 170, pp. 240-46.

K.N. Amato, S.M. Gaytan, L.E. Murr, E. Martinez, P.W. Shindo, J. Hernandez, S. Collins, and F. Medina: Acta Mater., 2012, vol. 60, pp. 2229-39.

J.J.S. Dilip, G.D. JanakiRam, and B.E. Stucker: Int. J. Rapid Manuf., 2012, vol. 3, pp. 56–69.

J.J.S. Dilip, S. Babu, S. VaradhaRajan, K.H. Rafi, G.D. JanakiRam, and B.E. Stucker: Mater. Manuf. Process., 2013, vol. 28, pp. 1–6.

R. Puli and G.D. Janaki Ram: Surf. Coat. Technol., 2012, vol. 207, pp. 310-18.

R. Puli and G.D. Janaki Ram: Mater. Charact., 2012, vol. 74, pp. 49-54.

F.J. Humphreys: Acta Mater., 1997, vol. 45, pp 4231-240.

Y. Wang, W.Z. Shao, L. Zhen, and B.Y. Zang: Mater. Sci. Eng. A, 2011, vol. 528, pp. 3218-227.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 27, 2013.

Rights and permissions

About this article

Cite this article

Dilip, J.J.S., Janaki Ram, G.D. Friction Freeform Fabrication of Superalloy Inconel 718: Prospects and Problems. Metall Mater Trans B 45, 182–192 (2014). https://doi.org/10.1007/s11663-013-0003-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-013-0003-x