Abstract

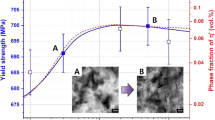

An aluminum-copper alloy of the A206 type was melt and cast in molds that promote a thermal gradient during solidification to study the effects that solidification rate exerts on the microstructure of the material. The stress-strain characteristics of heat-treated samples were related to microstructural parameters. The reactions occurring during solidification and cooling were detected and identified by means of thermal analyses. The microstructure of the material was assessed by measuring the secondary dendrite arm spacing, grain size, and porosity. It was found that these parameters increase as the solidification rate decreases. The material was heat treated to T4 and T7 conditions and tested in tension. The stress-strain curves were analyzed to determine the yield and ultimate strengths, as well as the strain to failure and that at which the ultimate strength was achieved. It was found that these properties are enhanced by microstructural refining in either testing condition. It was also found that porosity increased due to dissolution of copper-rich particles during heat treating. The best combination of strength and ductility were achieved in the T4 condition.

Similar content being viewed by others

References

W.E. Kosak: U.S. Patent 6,648,351, 2003

W.E. Kosak: U.S. Patent 6,742,808, 2004

I.J. Polmear: Light Alloys, Metallurgy of the Light Metals, Edward Arnold, London, 1980

L. Bäckerud, G. Chai, and J. Tamminen: Solidification Characteristics of Aluminum Alloys, vol. 2, Foundry Alloys, AFS/Skanaluminium, Des Plains, IL, 1990

J. Campbell: Castings, 2nd ed., Butterworth-Heinemann, Oxford, United Kingdom, 2003

R. Colás, E. Velasco, and S. Valtierra: in Castings, Handbook of Aluminum, vol. 1, Physical Metallurgy and Processes, G.E. Totten and D.S. MacKenzie, eds., M. Dekker, New York, NY, 2003, pp. 591–641

A. Keaney and E.L. Rooy: ASM Handbook, vol. 2, Properties and Selection of Nonferrous Alloys and Special-Purpose Materials, ASM INTERNATIONAL, Materials Park, OH, 1990, pp. 123–51

A.L. Keaney: ASM Handbook, vol. 2, Properties and Selection of Nonferrous Alloys and Special-Purpose Materials, ASM INTERNATIONAL, Materials Park, OH, 1990, pp. 152–77

E.L. Rooy: ASM Handbook, vol. 15, Castings, ASM INTERNATIONAL, Materials Park, OH, 1992, pp. 743–70

E. Velasco, J. Talamantes, S. Cano, S. Valtierra, J.F. Mojica, R. Colás: Metall. Mater. Trans. B, 1999, vol. 30B, pp. 773–78

R. Colás, A. Rodríguez, J. Talamantes, S. Valtierra: Int. J. Cast Met. Res., 2004, vol. 17, pp. 332–38

G.F. Vander Voort: Microsc. Today, 2005, vol. 13 (6), pp. 22–27

Standard Test Methods of Tension Testing Wrought and Cast Aluminum and Magnesium Alloy Products (Metric), ASTM B557M-94, ASTM International, West Conshohocken, PA, 1994

Standard Test Methods for Tension Testing of Metallic Materials (Metric), ASTM E8M-99, ASTM International, West Conshohocken, PA, 1999

J.L. Murray: Int. Met. Rev., 1985, vol. 30, pp. 211–33

M.I. Pope, M.J. Judd: Differential Thermal Analysis, Heyden, London, 1977

H. Biloni, W.J. Boettinger: Physical Metallurgy, 4th ed., R.W. Cahn, P. Haasen, eds., North Holland, Amsterdam, 1996, pp. 669–842

M.C. Flemmings, T.Z. Kattamis, B.P. Bardes: AFS Trans., 1981, vol. 91, pp. 501–06

J.E. Spinelli, D.M. Rosa, I.L. Ferreira, A. García: Met. Sci. Eng. A, 2004, vol. 382, pp. 271–82

A.-E.M. Assar: J. Mater. Proc. Technol., 1999, vol. 86, pp. 146–51

T. Din, A.K.M.B. Rashid, J. Campbell: Mater. Sci. Technol., 1996, vol. 12, pp. 269–75

C.H. Cáceres, T. Din, A.K.M.B. Rashid, J. Campbell: Mater. Sci. Technol., 1999, vol. 12, pp. 711–16

C.H. Cáceres: J. Mater. Eng. Perf., 2000, vol. 9, pp. 215–21

C.H. Cáceres, M. Makhlouf, D. Apelian, L. Wang: J. Light Met., 2001, vol. 1, pp. 51–59

Z. Li, A.M. Samuel, F.H. Samuel, C. Ravindran, H.W. Doty, S. Valtierra: Mater. Sci. Eng. A, 2004, vol. 367, pp. 96–110

Z. Li, A.M. Samuel, F.H. Samuel, C. Ravindran, H.W. Doty, S. Valtierra: Mater. Sci. Eng. A, 2004, vol. 367, pp. 111–22

R.E. Stoltz, R.M. Pelloux: Metall. Trans A, 1976, vol. 7A, pp. 1295–1306

P.G. McCormick: Scripta Metall., 1981, vol. 15, pp. 441–44

J.W. Martin: Micromechanisms in Particle Hardened Alloys, Cambridge University Press, Cambridge, United Kingdom, 1980

M. Drouzy, S. Jacob, M. Richard: AFS Int. Cast. Met. J., 1980, vol. 5, pp. 43–50

S.K. Sigworth and C.H. Cáceres: AFS Trans., 2004, vol. 112, pp. 372–86

R. Torres, J. Esparza, E. Velasco, S. García-Luna, R. Colás: Int. J. Microstruct. Mater. Prop., 2006, vol. 1, pp. 129–38

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 19, 2008.

Rights and permissions

About this article

Cite this article

Talamantes-Silva, M., Rodríguez, A., Talamantes-Silva, J. et al. Effect of Solidification Rate and Heat Treating on the Microstructure and Tensile Behavior of an Aluminum-Copper Alloy. Metall Mater Trans B 39, 911–919 (2008). https://doi.org/10.1007/s11663-008-9204-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-008-9204-0