Abstract

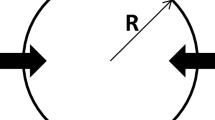

This article involves the evaluation of the volume change of iron-oxide-carbon composite pellets and its implications on reduction kinetics under conditions prevalent in a rotary hearth furnace (RHF) that were simulated in the laboratory. The pellets, in general, were found to shrink considerably during the reduction due to the loss of carbon and oxygen from the system, sintering of the iron-oxide, and formation of a molten slag phase at localized regions inside the pellets due to the presence of binder and coal/wood-charcoal ash at the reduction temperatures. One of the shortcomings of the RHF ironmaking process has been the inability to use multiple layers of composite pellets because of the impediment in heat transport to the lower layers of a multilayer bed. However, pellet shrinkage was found to have a strong effect on the reduction kinetics by virtue of enhancing the external heat transport to the lower layers. The volume change of the different kinds of composite pellets was studied as a function of reduction temperature and time. The estimation of the change in the amount of external heat transport with varying pellet sizes for a particular layer of a multilayer bed was obtained by conducting heat-transfer tests using inert low-carbon steel spheres. It was found that if the pellets of the top layer of the bed shrink by 30 pct, the external heat transfer to the second layer increases by nearly 6 times.

Similar content being viewed by others

Notes

FactSage is a trademark of Thermfact Ltd., and CRCT (Montreal, Canada) and GTT-Technologies (Aachen, Germany)

References

K.N. Pargeter, R.H. Hanewald, D.E. Dombrowski: Conserv. Recycl., 1985, vol. 8, pp. 363–75

R. Degel, O. Metelmann, and H. Lehmkuhler: Electric Furnace Conf. Proc., Iron & Steel Society, Warrendale, PA, 2000, pp. 519–33

Y. Sawa, T. Yamamoto, K. Takeda, H. Itaya: ISIJ Int., 2001, vol. 41, pp. S17–S21

O.M. Fortini: Doctoral Thesis, Carnegie Mellon University, Pittsburgh, PA, 2004

C.E. Seaton, J.S. Foster, J. Velasco: Trans. ISIJ, 1983, vol. 23, pp. 497–503.

E. Donskoi, D.L.S. McElwain: Ironmaking and Steelmaking, 2001, vol. 28 (5), pp. 384–89

O.M. Fortini, R.J. Fruehan: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 709–17

S. Halder and R.J. Fruehan: Metall. Mater. Trans. B, 2008, vol. 39B. DOI: 10.1007/s11663-008-9203-1

S.V. Patankar: Numerical Heat Transfer and Fluid Flow, Hemisphere Publishing Company, New York, 1980, pp. 56–57

R.M. German: Sintering Theory and Practice, John Wiley & Sons, New York, 1996

S. Halder: Doctoral Thesis, Carnegie Mellon University, Pittsburgh, PA, 2007

Acknowledgments

The authors thank the member companies of the Center for Iron and Steel Making Research (CISR) for the financing of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 15, 2008.

Rights and permissions

About this article

Cite this article

Halder, S., Fruehan, R. Reduction of Iron-Oxide-Carbon Composites: Part III. Shrinkage of Composite Pellets during Reduction. Metall Mater Trans B 39, 809–817 (2008). https://doi.org/10.1007/s11663-008-9201-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-008-9201-3