Abstract

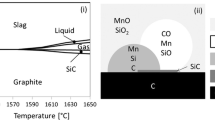

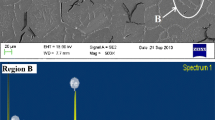

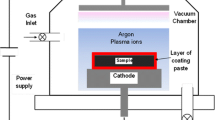

Due to their excellent thermal shock and wear resistance at high temperatures, alumina-carbon based refractories are used extensively in the steel industry. A clear understanding of factors affecting the dissolution of carbon from refractories is of crucial importance, as carbon depletion from the refractory can significantly deteriorate refractory performance and metal quality. Atomistic simulations on the alumina-graphite/liquid iron system have shown that nonwetting between alumina and liquid iron is an important factor inhibiting the penetration of liquid metal in the refractory matrix and limiting carbon dissolution. This study investigates the role played by the carbonaceous material in the dissolution of carbon from the refractory composite. Two carbonaceous materials, namely, petroleum coke and natural graphite, respectively, containing 0.35 and 5.26 pct ash, were used in this study. Substrates were prepared from mixtures of alumina and carbon over a wide concentration range. Using a sessile drop arrangement, carbon pickup by liquid iron from alumina-carbon mixtures was measured at 1550 °C and was compared with the carbon pickup from alumina-synthetic graphite mixtures. These studies were supplemented with wettability measurements and microscopic investigations on the interfacial region. For high alumina concentrations (>40 wt pct), carbon dissolution from refractory mixtures was found to be negligible for all carbonaceous materials under investigation. Significant differences however were observed at lower alumina concentrations. Carbon dissolution from alumina-petroleum coke mixtures was much lower than the corresponding dissolution from alumina synthetic graphite-mixtures and was attributed to poor wettability of petroleum coke with liquid iron, its structural disorder, and the presence of sulfur. Very high levels of carbon dissolution, however, were observed from alumina-natural graphite mixtures, with carbon pickup by liquid iron from mixtures with up to 30 wt pct alumina reaching saturation. A sharp reduction to near zero levels was observed in the 30 to 40 wt pct alumina range. Along with implications for commercial refractory applications, these results are discussed in terms of material characteristics, interactions between ash impurities and alumina, and formation of complexes in the interfacial region.

Similar content being viewed by others

References

http://www.vrwrefractories.com/iron-steel-industry.html

K. Sasai and Y. Mizukami: Iron Steel Inst. Jpn. Int., 1995, vol. 35 (1), pp. 26–33.

A. Schei, J.K. Tuset, and H. Tverit: Production of High Silicon Alloys, Tapir Forlaug, Trondheim, 1998.

C. Chen, C. Lin, and S. Chen: Br. Ceram. Trans., 2000, vol. 99 (2), pp. 57–62.

D.H. Hubble: in The Making, Shaping and Treating of Steel, R.J. Fruehan, ed., The AISE Steel Foundation, Pittsburgh, PA, 1998, pp. 159–226.

W.E. Lee and S. Zhang: Int. Mater. Rev., 1999, vol. 44 (3), pp. 77–105.

Y.V. Naidich and G.A. Kolesnichenko: in Surface Phenomena in Metallurgical Processes, A.I. Belyaev, ed., Consultants Bureau, New York, NY, 1965, pp. 218–23.

V. Sahajwalla and R. Khanna: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 1517–25.

J.F. Elliot, M. Gleiser, and V. Ramakrishna: Thermochemistry for Steelmaking, Addison-Wesley, Reading, MA, 1963.

G.Z. Ruan and N. Li: Ironmaking and Steelmaking, 2004, vol. 31 (4), pp. 342–42.

G.Z. Ruan, N. Li, and X. Wu: Am. Ceram. Soc. Bull., 2005, vol. 84 (10), pp. 9101–04.

L. Zhao and V. Sahajwalla: Iron Steel Inst. Jpn. Int., 2003, vol. 43 (1), pp. 1–6.

E.M.M. Ewais: J. Ceram. Soc. Jpn., 2004, vol. 112 (10), pp. 517–32.

M.A. Boucher: http://www.nrcan.gc.ca/mms/cmy/content/1994/29.pdf, pp. 1–9.

V. Sahajwalla and R. Khanna: Acta Mater., 1999, vol. 47 (3), pp. 793–800.

C. Wu, R. Wiblen, and V. Sahajwalla: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 1099–104.

M.B. Maurao, G.G. Krishna Murthy, and J.F. Elliot: Metall. Mater. Trans. B, 1993, vol. 24B, pp. 629–37.

V. Sahajwalla and R. Khanna: Yazawa Int. Symp., San Diego, CA, 2003, pp. 825–40.

S.O. Ericsson and P.O. Melberg: Scand. J. Metall., 1981, vol. 10, pp. 15–18.

V.A. Grigoryan and V.P. Karshin: Russ. Metall., 1972, vol. 1, pp. 78–91.

R. Olivares: Ph.D. Thesis, The University of New Castle, New Castle, Austalia, 1997.

C. Wu and V. Sahajwalla: Metall Mater. Trans. B, 2000, vol. 31B, pp. 215–56.

S. Orsten and F. Oeters: W.O. Philbrook Memorial Symp., ISS, Warrendale, PA, (1988), pp. 27–38.

S.T. Cham, V. Sahajwalla, R. Sakurovs, H. Sun, and M. Dubikova: Iron Steel Inst. Jpn. Int., 2004, vol. 44 (11), pp. 1835–41.

V. Sahajwalla and R. Khanna: Scand. J. Metall., 2003, vol. 32 (1), pp. 53–57.

F. McCarthy: Ph.D. Thesis, The University of New South Wales, Sydney, 2005.

J. Morris and D. Buehl: J. Met., 1950, vol. 188, pp. 317–25.

R. Khanna and V. Sahajwalla: Acta Mater., 2005, vol. 53 (4), pp. 1205–14.

J.M. Toguri, T. Takasu, and K. Mukai: The Brimacombe Memorial Symp., G.A. Irons and A.W. Cramb, eds., Vancouver, 2000, pp. 485–501.

L. Zhao: Ph.D. Thesis, The University of New South Wales, Sydney, 2003.

F. McCarthy, C. Wu, V. Sahajwalla, and J. Hart: Metall. Trans. B, 2003, vol. 34B, pp. 573–80.

C. Wu and V. Sahajwalla: Metall. Trans. B, 2000, vol. 31B, pp. 243–51.

W.E. Lee and R.E. Moore: J. Am. Ceram. Soc., 1998, vol. 81 (6), pp. 1385–1441.

W.E. Lee, S. Zhang, and H. Sarpoolaky: Ceram. Trans., 2001, vol. 125, pp. 245–52.

Slag Atlas, 2nd ed., Verlag Stahleisen GmbH, Dusseldorf, Germany, 1995.

FactSage™, version 5.2, Thermfact Ltd./Ecole Polytechnique CRCT, Montreal, and GTT-Technologies GmbH, Aachen, 2003.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Khanna, R., Sahajwalla, V., Rodgers, B. et al. Dissolution of carbon from alumina-carbon mixtures into liquid iron: Influence of carbonaceous materials. Metall Mater Trans B 37, 623–632 (2006). https://doi.org/10.1007/s11663-006-0046-3

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-006-0046-3