Abstract

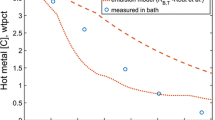

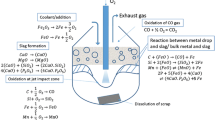

In basic oxygen steelmaking, the major portion of the refining is realized through reactions between metal droplets and slag. The residence time of metal droplets in the slag crucially influences the productivity. A model for the prediction of trajectory and residence time of metal droplets in slags has been developed based on mechanics and chemical kinetics principles. When there is no decarburization, analysis of the ballistic motion of metal droplets in the slag predicts very short residence times (<1 second). This result demonstrates that when decarburization is very weak, the metal droplets spend a very short time in the slag. This could explain in part the poor kinetic behavior in the end stage of the blow. During active decarburization metal droplets normally become bloated, resulting in a decreased apparent density. Accounting for this, the ballistic model predicts residence times ranging from 10 to 200 seconds, which are much more in keeping with practical experience and previous laboratory studies. Excellent agreement between the model and laboratory measurements, combined with reasonable predictions of industrial residence times, shows that this model can be used to provide a much improved understanding of theoretical aspects of oxygen steelmaking.

Similar content being viewed by others

References

H.W. Meyer, W.F. Porter, G.C. Smith, and J. Szekely: J. Met., 1968, July, pp. 35–42.

C. Cicutti, M. Valdez, T. Pérez, J. Petroni, A. Gómez, R. Donayo, and L. Ferro: Study of Slag-Metal Reactions in an LD-LBE Converter, Proc. Slag Conf., Stockholm, 2000.

E.W. Mulholland, G.S.F. Hazeldean, and M.W. Davies: J. Iron Steel Inst., 1973, vol. 211, pp. 632–39.

T. Gare and G.S.F. Hazeldean: Ironmaking and Steelmaking, 1981, No. 4, pp. 169–181.

H. Gaye and P.V. Riboud: Metall. Trans. B, 1977, vol. 8B, pp. 409–15.

D.J. Min and R.J. Fruehan: Metall. Trans. B, 1992, vol. 23B, pp. 29–37.

C.L. Molloseau and R.J. Fruehan: Metall. Trans. B, 2002, vol. 33B, pp. 335–44.

Brahma Deo, Arun Karamcheti, Amitava Paul, Pankaj Singh, and R.P. Chhabra: Iron Steel Inst. Jpn. Int., 1996, vol. 36 (6), pp. 658–66.

Subagyo and G. Brooks: Iron Steel Inst. Jpn. Int., 2002, vol. 42 (10), pp. 1182–84.

Subagyo, G.A. Brooks, and K. Coley: Can. Metall. Q., 2005, vol. 44 (1), pp. 119–29.

J. Schoop, W. Resch, and G. Mahn: Ironmaking and Steelmaking, 1978, vol. 2, pp. 72–79.

D.J. Price: in Process Engineering of Pyrometallurgy, M.J. Jones, ed., The Institution of Mining and Metallurgy, London, 1974, pp. 8–15.

B. Trentini: Trans. TMS-AIME, 1968, vol. 242, pp. 2377–88.

P. Kozakevitch: JOM, 1969, vol. 22 (7), pp. 57–68.

A. Chatterjee, N.O. Lindfors, and J.A. Wester: Ironmaking and Steelmaking, 1976, vol. 3 (1), pp. 21–32.

R.C. Urquhart and W.G. Davenport: Can. Metall. Q., 1973, vol. 12 (4), pp. 507–16.

N. Standish and Q.L. He: Iron Steel Inst. Jpn. Int., 1989, vol. 29, No. 6, pp. 455–461.

Q.L. He and N. Standish: Iron Steel Inst. Jpn. Int., 1990, vol. 30, No. 4, pp. 305–309.

Q.L. He and N. Standish: Iron Steel Inst. Jpn. Int., 1990, vol. 30, No. 5, pp. 356–361.

G. Turner and S. Jahanshahi: Trans. Iron Steel Inst. Jpn., 1987, vol. 27, pp. 734–39.

S.C. Koria and K.W. Lange: Ironmaking and Steelmaking, 1983, vol. 10 (4), pp. 160–68.

S.C. Koria and K.W. Lange: Metall. Trans. B, 1984, vol. 15B, pp. 109–16.

S.C. Koria and K.W. Lange: Ironmaking and Steelmaking, 1986, vol. 13 (5), pp. 236–40.

Subagyo, G.A. Brooks, K.S. Coley, and G.A. Irons: Iron Steel Inst. Jpn. Int., 2003, vol. 43 (7), pp. 983–89.

Subagyo, G.A. Brooks, and K. Coley: Interfacial Area in Top Blown Oxygen Steelmaking, Steelmaking Conf. Proc., ISS, Warrendale, PA, 2002, vol. 85, pp. 749–62.

Gary J. Lastman and Naresh K. Sinha: Microcomputer-Based Numerical Methods for Science and Engineering, Saunders College Publishing, a Division of Holt, Rinehart and Winston, Inc., New York, NY, 1989, pp. 211–15.

R. Higbie: Trans. Am. Inst. Chem. Eng., 1935, vol. 35, pp. 365–89.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Brooks, G., Pan, Y., Subagyo et al. Modeling of trajectory and residence time of metal droplets in slag-metal-gas emulsions in oxygen steelmaking. Metall Mater Trans B 36, 525–535 (2005). https://doi.org/10.1007/s11663-005-0044-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-005-0044-x