Abstract

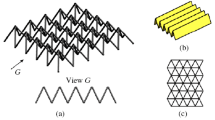

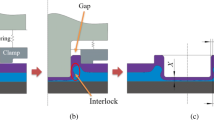

Wrought metallic sandwich structures with open cell truss cores are a relatively new class of multifunctional material systems that can be made using affordable deformation, assembly, and joining processes. Here, the design and fabrication of these types of structures from wrought, heat-treatable aluminum alloys is reported. Tetrahedral truss cores were made by bending perforated aluminum alloy sheets. Plain square weave truss cores were made by stacking and aligning precrimped aluminum alloy weaves. Both core types were metallurgically bonded between braze clad aluminum alloy facesheets using a vacuum brazing approach. With this method, affordable truss core sandwich structures can be made from a variety of wrought aluminum and other alloys. Design methodology and multifunctional applications are discussed.

Similar content being viewed by others

References

A.G. Evans: MRS Bull., 2001, Oct., pp. 790–97.

J.C. Wallach and L.J. Gibson: Int. J. Solids Structures, 2001, vol. 38, pp. 7181–96.

V.S. Deshpande and N.A. Fleck: Int. J. Solids Structures, 2001, vol. 38, pp. 6275–6305.

N. Wicks and J.W. Hutchinson: Int. J. Solids Structures, 2001, vol. 38, pp. 5165–83.

D.J. Sypeck and H.N.G. Wadley: J. Mater. Res., 2001, vol. 16 (3), pp. 890–97.

S. Chiras, D.R. Mumm, A.G. Evans, N. Wicks, J.W. Hutchinson, K. Dharmasena, H.N.G. Wadley, and S. Fichter: Int. J. Solids Structures, 2002, vol. 39, pp. 4093–4115.

D.J. Sypeck and H.N.G. Wadley: Adv. Eng. Mater., 2002, vol. 4 (10), pp. 759–64.

A.G. Evans, J.W. Hutchinson, N.A. Fleck, M.F. Ashby, and H.N.G. Wadley: Progr. Mater. Sci., 2001, vol. 46, pp. 309–27.

M.F. Ashby, A.G. Evans, N.A. Fleck, L.J. Gibson, J.W. Hutchinson, and H.N.G. Wadley: Metal Foams: A Design Guide, Butterworth-Heinemann, Boston, MA, 2000.

L. Christodoulou and J.D. Venables: JOM, 2003, Dec., pp. 39–45.

HexWeb™ Honeycomb Attributes and Properties, Publication No. TSB 120, Hexcel Composites, Pleasanton, CA, 1999.

M.L. Renauld, A.F. Giamei, M.S. Thompson, and J. Priluck: Porous and Cellular Materials for Structural Applications, Materials Research Society Symposia Proceedings 521, D.S. Schwartz, D.S. Shih, A.G. Evans, and H.N.G. Wadley, eds., Materials Research Society, Warrendale, PA, 1998, pp. 109–17.

D.J. Sypeck: in Processing and Properties of Lightweight Cellular Metals and Structures, A. Ghosh, T. Sanders, and D. Claar, eds., TMS, Warrendale, PA, 2002, pp. 35–45.

Adv. Mater. Processes, 2000, vol. 158 (6).

J. Tian, T. Kim, T.J. Lu, H.P. Hodson, D.T. Queheillalt, D.J. Sypeck, and H.N.G. Wadley: Int. J. Heat Mass Transfer, 2004, vol. 47, pp. 3171–86.

T.J. Lu, H.A. Stone, and M.F. Ashby: Acta Mater., 1998, vol. 46 (10), pp. 3619–35.

K, Tashiro: U.S. Patent No. 6,207,256 B1, Mar. 27, 2001.

S.T. Brittain, Y. Sugimura, O.J.A. Schueller, A.G. Evans, and G.M. Whitesides: J. Microelectromech. Systems, 2001, vol. 10 (1), pp. 113–20.

Aluminum Brazing Handbook, 4th ed., The Aluminum Association, Washington DC, 1990.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sypeck, D.J. Wrought aluminum truss core sandwich structures. Metall Mater Trans B 36, 125–131 (2005). https://doi.org/10.1007/s11663-005-0012-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-005-0012-5