Abstract

Downsizing and decommissioning of nuclear facility operations is increasing the stockpile of various different grades of radioactive scrap iron (RSI). Disposal of this material not only represents significant resource and value lost but also necessitates long term monitoring for environmental compliance. The latter results in additional recurring expense. It is desirable to be able to decontaminate the RSI to a very low level that can be recycled or used for fabrication of containers for RSI disposal instead of using virgin metal to fabricate the container.

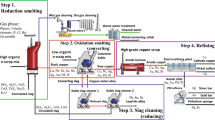

Electroslag remelting and refining (ESR) is often used for decontaminating radioactive contaminated sources of scrap iron, such as stainless steel. Nonradioactive oxides of cerium are used to simulate the radioactive oxide contaminants of uranium and plutonium. The success of the ESR process is strongly dependent on having the right thermo-physical-and-chemical slag properties. In this article, we measured the following relevant slag properties: capacity to incorporate the radioactive contaminant (simulant), volatilization rate and volatile species, electrical conductivity, viscosity, surface tension, and slag-metal partition coefficient, as a function of temperature. The impact of these properties on the ESR decontamination process is discussed.

Similar content being viewed by others

References

T.E. Bechtold: “Winco Metal Recycle Annual Report FY 1993,” WINCO-1172, United States Department of Energy, Idaho Falls, ID, 1993.

J.M.R. Buckentin: Ph.D. Thesis, Oregon Graduate Institute of Science and Technology, 1996.

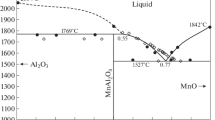

E.M. Levin, C.R. Robbins, and H.F. McMurdie: Phase Diagrams for Ceramists Vol. 1, M.K. Reser, ed., The American Ceramic Society, Columbus, OH, 1964, p. 476, Figure 1707.

W.P. Chernicoff, C.J. MacDonald, and U.B. Pal: Global Symp. on Recycling, Waste Treatment and Clean Technology, San Sebastian, Spain, TMS, Warrendale, PA, 1999, pp. 803–12.

S.L. Schiefelbein and D.R. Sadoway: Metall. Mater. Trans. B, 1997, vol. 28B, pp. 1141–49.

N.A. Fried: Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, 1996.

C.J. Macdonald: Master’s Thesis, Boston University, MA, 2000.

V.D. Eisenhüttenleute: Slag Atlas, Verlag Stahleisen m.b.H., Düsseldorf, 1981, pp. 258–82.

K.C. Mills and B.J. Keene: Int. Met. Rev., 1981, No. 1, pp. 21–69.

V.D. Eisenhüttenleute: Slag Atlas, Verlag Stahleisen m.b.H., Düsseldorf, 1981, pp. 190–91.

V.D. Eisenhüttenleute: Slag Atlas, Verlag Stahleisen m.b.H., Düsseldorf, 1981, pp. 232–33.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pal, U.B., MacDonald, C.J., Chiang, E. et al. Behavior of ceria as an actinide surrogate in electroslag remelting and refining slags. Metall Mater Trans B 32, 1119–1128 (2001). https://doi.org/10.1007/s11663-001-0100-0

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11663-001-0100-0