Abstract

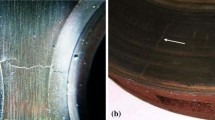

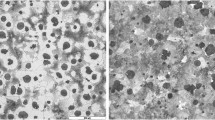

This study investigates the thermal fatigue cracking behavior of high-silicon spheroidal graphite (SG) cast iron. Irons with different residual magnesium contents ranging from 0.038 to 0.066 wt pct are obtained by controlling the amount of spheroidizer. The repeated heating/cooling test is performed under cyclic heating in various temperatures ranging from 650 °C to 800 °C. Experimental results indicate that the thermal fatigue cracking resistance of high-silicon SG cast iron decreases with increasing residual magnesium content. The shortest period for crack initiation and the largest crack propagation rate of the specimens containing 0.054 and 0.060 wt pct residual magnesium contents are associated with heating temperatures of 700 °C and 750 °C. Heating temperatures outside this range can enhance the resistance to thermal fatigue crack initiation and propagation. When thermal fatigue cracking occurs, the cracks always initiate at the surface of the specimen. The major path of crack propagation is generally along the eutectic cell-wall region among the ferrite grain boundaries, which is the location of MgO inclusions agglomerating together. On the other hand, dynamic recrystallization of ferrite grains occurs when the thermal cycle exceeds a certain number after testing at 800 °C. Besides, dynamic recrystallization of the ferrite matrix suppresses the initiation and propagation of thermal fatigue cracking.

Similar content being viewed by others

References

Y.J. Park, R.B. Gundlach, R.G. Thomas, and J.F. Janowak: AFS Trans., 1985, vol. 93, pp. 415–22.

Y.J. Park, R.B. Gundlach, and J.F. Janowak: AFS Trans., 1990, vol. 98, pp. 267–72.

K. Roehrig: AFS Trans., 1978, vol. 86, pp. 75–88.

S.C. Lee and L.C. Weng: Metall. Trans. A, 1991, vol. 22A, pp. 1821–31.

M.C. Rukadikar and G.P. Reddy: AFS Trans., 1988, vol. 96, pp. 351–60.

K.R. Ziegler and J.F. Wallace: AFS Trans., 1984, vol. 92, pp. 735–48.

H. Fredriksson, P.-A. Sunnerkrantz, and P. Ljubinkovic: Mater. Sci. Technol., 1988, vol. 4, pp. 222–26.

J.F. Janowak, J.D. Crawford, and K. Roehrig: Casting Eng./Foundry World, 1982, vol. 14, pp. 32–41.

J.F. Janowak: AFS Int. Cast. Met. J., 1981, pp. 28–41.

M.C. Rukadikar and G.P. Reddy: J. Mater. Sci., 1986, vol. 21, pp. 4403–10.

C.P. Cheng, S.M. Chen, T.S. Lui, and L.H. Chen: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 325–34.

S.F. Chen, T.S. Lui, and L.H. Chen: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 557–61.

A. Weronski: Thermal Fatigue of Metals, Marcel Dekker, Inc., New York, NY, 1991, p. 175.

S.I. Karsay: Ductile Iron II, Quebec Iron and Titanium Corporation, Illinois, USA, 1971, Ch. 1.

M. Sofue, S. Okada, and T. Sasaki: AFS Trans., 1970, vol. 78, pp. 173–82.

M. Sofue: Imono, 1975, vol. 47, pp. 681–87.

O. Yanagisawa and T.S. Lui: Trans. JIM, 1983, vol. 24, pp. 858–67.

Y.F. Lin, T.S. Lui, and L.H. Chen: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 821–25.

M. Takanezawa, Y. Kobayashi, and Y. Tomota: J. JFS, 1997, vol. 69, pp. 41–48.

R.N. Wright and T.R. Farrell: AFS Trans., 1977, vol. 85, pp. 853–66.

Y. Iwabuchi, I. Kobayashi, H. Narita, and T. Takenouchi: J. JFS, 1996, vol. 68, pp. 209–15.

S.F. Chen, T.S. Lui, and L.H. Chen: Cast Met., 1994, vol. 6, pp. 199–203.

D.M. Stefanescu: Metals Handbook, 10th ed., ASM INTERNATIONAL, Metals Park, OH, 1990, vol. 1, p. 64.

W.D. Kingery: J. Am. Ceram. Soc., 1955, vol. 38, pp. 3–15.

C.P. Cheng, T.S. Lui, and L.H. Chen: Cast Met., 1996, vol. 8, pp. 211–16.

G. Gottstein and S. Chen: Int. Conf. on Recrystallization in Metallic Materials, The Minerals, Metals & Materials Society, Pennsylvania, USA, 1990, pp. 69–78.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Cheng, C.P., Lui, T.S. & Chen, L.H. Effect of residual magnesium content on thermal fatigue cracking behavior of high-silicon spheroidal graphite cast iron. Metall Mater Trans A 30, 1549–1558 (1999). https://doi.org/10.1007/s11661-999-0092-y

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-999-0092-y