Abstract

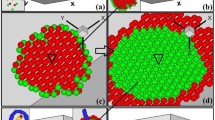

Dimpled fracture via void nucleatïon, growth, and coalescence is common in alloys containing hard particles or inclusions, which act as void nucleation sites. Void-covered fracture surfaces have also been observed in planar slip materials. However, the process by which dimples from in the planar slip materials is not understood because these materials generally do not contain hard particles or inclusions. An intersecting slip process was recently proposed as a possible mechanism for the formation of dimpled fracture in the planar slip materials. In this article, experimental evidence of void nucleation and growth on planar slip bands in a Nb-Cr-Ti solid-solution alloy (Nb-13Cr-37Ti, in at. pct) is presented. The experimental observations are compared against the intersecting slip model and a peierls stress calculation to elucidate the mechanism of dimpled fracture in planar slip materials.

Similar content being viewed by others

References

K.D. Puttick: Phil. Mag., 1959, vol. 4, pp. 964–69.

T.J. Baker and J.A. Charles: J. Iron Steel Inst., 1972, vol. 210, pp. 702–06.

G.T. Hahn and A.R. Rosenfield: Metall. Trans. A, 1975, vol. 6A, pp. 653–68.

J.C. Chesnutt, C.G. Rhodes, and J.C. Williams: Fractography—Microscopic Cracking Processes, ASTM STP 600, C.D. Beachem and W.R. Warke, eds., ASTM, Philadelphia, PA, 1976, pp. 99–138.

Kwai S. Chan: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 2518–31.

D.L. Davidson, K.S. Chan, and D.L. Anton: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 3007–18.

J. Dipasquale, D. Gahutu, D. Konitzer, and W. Soboyejo: Materials Research Society Proceedings, Materials Research Society, Pittsburgh, PA, 1995, vol. 364, pp. 1347–52.

V.K. Sikka and E.A. Loria: Mater. Sci. Eng., 1997, vols. 239–240, pp. 745–51.

M.G. Medira, R. Goetz, D.M. Dimiduk, and J.J. Lewandowski: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 1767–76.

K.S. Chan: Metall. Trans. A, 1992, vol. 23A, pp. 183–99.

H. Chiu and X. Mao: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 3817–25.

A.H. Cottrell: Trans. AIME, 1958, vol. 212, pp. 192–203.

A.N. Stroh: Proc. R. Soc. A, 1954, vol. 223, pp. 597–606.

Kwai S. Chan: in Recent Advances in Fracture, R.K. Mahidhara, A.B. Geltmacher, P. Matic, and K. Sadananda, eds., TMS, Warrendale, PA, 1997, pp. 137–57.

A. Nagy, J.B. Campbell, and D.L. Davidson: Rev. Sci. Instrum., 1984, vol. 55, pp. 778–82.

K.S. Chan and D.L. Davidson: Metall. Mater. Trans. A, 1999 (in press).

H.C. Rogers: Trans. TMS-AIME, 1960, vol. 218, pp. 498–506.

K.S. Chan: in Micromechanics of Advanced Materials, S.N.G. Chu, P.K. Liaw, K.S. Chan, R.J. Arsenault, K. Sadananda, W.W. Gerberch, C.C. Chau, and T.M. Chung, eds., TMS, Warrendale, PA, 1995, pp. 113–20.

J.N. Wang: Acta Metall., 1996, vol. 44, pp. 1541–46.

A.J.E. Foreman: Acta Metall., 1955, vol. 3, pp. 322–30.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chan, K.S., Davidson, D.L. Evidence of void nucleation and growth on planar slip bands in a Nb-Cr-Ti alloy. Metall Mater Trans A 30, 579–585 (1999). https://doi.org/10.1007/s11661-999-0049-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-999-0049-1