Abstract

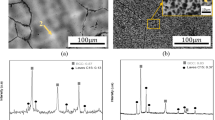

The microstructure and properties of Cu-C pseudoalloy films prepared by R.F. magnetron sputtering have been investigated. As Cu and C are mutually immiscible, nonequilibrium supersaturated solid solutions of C in Cu with nanocrystalline microstructures were observed in as-deposited films. Upon heating of the films, three major transition events took place. Recovery occurred at ∼280 to 300 °C, while at ∼400 °C, crystallites started to growth and coalescence, due to the release of strain energies stored during deposition. Annealing at above 600 °C led to the occurrence of grain growth and altered the microstructure considerably. Although attempts have been made in this study, a possible annealing-induced phase separation could not be unambiguously identified. Yet, the fact of low twin densities and fine grain structures observed in the annealed films suggests that the extensive grain growth was impeded by the presence of carbon. Resistivity and hardness properties correlated well with the film microstructure and were governed by the impurity effect of carbon. Low-carbon Cu-C films yielded relatively low resistivity, attributable to the improved film microstructure. Hardness results indicated the strengthening of films was mainly due to fine structure, presence of carbon, and grain refinement by annealing twins.

Similar content being viewed by others

References

H. Wang: Ph.D. Dissertation, University of Illinois at Urbana-Champaign, Urbana, IL, 1994, pp. 1–124.

R.T. Carson, H.S. Savage, and J.M. Rigsbee: in PVD Fabrication of Nanocrystalline Composite Materials, V.A. Ravi and T.S. Srivatsan, eds., TMS, Warrendale, PA, 1992, pp. 361–75.

G. Ramanath, H.Z. Xiao, L.C. Yang, A. Rockett, and L.H. Allen: J. Appl. Phys., 1995, vol. 78 (4), pp. 2435–40.

D.L. Ellis and D.L. McDanels: Metall. Trans. A, 1993, vol. 24A, pp. 43–52.

M. Ohring: Materials Science of Thin Film, Academic Press, Boston, MA, 1991, pp. 113–566.

C.D. Wagner, W.M. Riggs, I.E. Davis, J.F. Moulder, and G.E. Muilenberg: Handbook of X-ray Photoelectron Spectroscopy, Perkin-Elmer, Eden Prairie, MN, 1979.

B.D. Cullity: Elements of X-Ray Diffraction, 2nd ed., Addison-Wesley, Reading, MA, 1978, pp. 350–68.

J.P. Chu, C.H. Chung, P.Y. Lee, and J.M. Rigsbee: National Taiwan Ocean University, Keelung, Taiwan, unpublished research, 1996.

D.W. Brown, E.P. Donovan, C.M. Cotell, and K.S. Grabowski: Mater. Res. Soc. Symp. Proc., 1992, vol. 235, pp. 729–34.

R.D. Shull: Thermal Analysis in Metallurgy, R.D. Shull and A. Joshi, eds., TMS, Warrendale, PA, 1992, pp. 95–119.

R.E. Reed-Hill and R. Abbaschian: Physical Metallurgy Principles, 3rd ed., PWS, Boston, MA, 1991, pp. 227–71.

CRC Handbook of Chemistry and Physics, 65th ed., CRC Press, Boca Raton, FL, 1984–85, p. D-187.

J.P. Chu, J.W. Chang, and P.Y. Lee: Mater. Chem. Phys., 1997, vol. 50, pp. 31–36.

J.P. Chu, J.W. Chang, P.Y. Lee, J.K. Wu, and J.Y. Wang: Thin Solid Films, in press.

C.T. Huang and J.G. Duh: Surf. Coat. Technol., 1995, vol. 71, pp. 259–66.

B. Window, M.V. Swain, and G.L. Harding: Surf. Coat. Technol., 1991, vol. 49, pp. 199–202.

B. Window, G.L. Harding, C. Horrigan, and T. Bell: J. Vac. Sci. Technol., 1992, vol. A10, pp. 3278–82.

J.S. Benjamin and T.E. Volin: Metall. Trans., 1974, vol. 5, pp. 1929–34.

R. Venkatraman, J.C. Bravman, W.D. Nix, P.W. Davies, P.A. Flinn, and D.B. Fraser: J. Electronic Mater., 1990, vol. 19, pp. 1231–37.

R.E. Smallman: Modern Physical Metallurgy, 4th ed., Butterworth and Co., London, 1985, pp. 335–79.

J.P. Chu, J.M. Rigsbee, G. Banaś, F.V. Lawrence, and H.E. Elsayed-Ali: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 1507–17.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chu, J.P., Lee, P.Y., Chung, C.H. et al. Microstructure and properties of Cu-C pseudoalloy films prepared by sputter deposition. Metall Mater Trans A 29, 647–658 (1998). https://doi.org/10.1007/s11661-998-0145-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-998-0145-7