Abstract

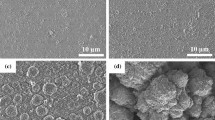

Solidification of hot dip coatings was studied regarding thermal conditions. Optical phenomena occurring at the liquid zinc surface were documented and the solid zinc surface was characterized in respect to optical and microscopic appearance, distribution of Pb and Al, crystal orientation, and topography. Resulting from these observations, a solidification model can be derived: zinc nucleation occurs at the steel/zinc interface. Due to thermal conditions in the slightly undercooled liquid zinc film, solidification occurs by rapid sideways dendritic expansion of the nucleated grains along the steel/zinc interface.

Dendritic growth is controlled by interaction of crystal orientation of the nucleated zinc grain and thermal conditions in the undercooled layer. This leads to formation of different shaped grains with thicker and thinner sectors. The mechanism of sideways expansion continues until the entire interface is covered with dendritic zinc grains. Even though the zinc outer surface is still a liquid phase, final spangle size, as well as surface appearance and shape of the grains, is already determined at that early stage of solidification. Further growth only leads to a thickening of the solid layer; however, its relief remains almost unchanged. Thickening occurs relatively slowly due to the fact that marginal heat flow toward the surface now represents the limiting factor.

Growth of the solid zinc layer results in continuous enrichment of Pb and Al in the residual liquid. Then, outer surface solidification starts as segments of single grains emerge. Distribution of the enriched residual melt in between the already solid areas depends on the relief of the solid layer. Finally, eutectic Zn-Pb reaction with precipitation of Pb particles takes place, which defines the dull appearance of these regions. Solidification for “lead-free” coatings is essentially the same, except that the final eutectic Zn-Pb reaction is missing. Additional investigations of dendritic secondary arm spacing indicate that Pb does not act by suppressing zinc nucleation. Pronounced dendritic growth is proposed to be favored by a change in interfacial energy. The new solidification model is applicable for a wide range of processing conditions and explains the origin of the typical spangle structure.

Similar content being viewed by others

References

R. Kiusalaas, G. Engberg, H. Klang, E. Schedin, and L. Schön: GALVATECH ’89, Proc. Int. Conf. on Zinc and Zinc Alloy Coated Steel Sheet, 1989, The Iron and Steel Institute of Japan, Tokyo, 1989, pp. 485–92.

F.A. Fasoyinu and F. Weinberg: Metall. Trans. B, 1990, vol. 21B, pp. 549–58.

D.I. Cameron and C.J. Harvey: Proc. 8th Int. Hot Dip Galvanizing Conf., London, 1967, Zinc Development Association, London, 1967, pp. 86–97.

Y. Fukui, M. Koda, and Y. Hirose: Tetsu-to-Hagané, 1991, vol. 77, pp. 939–46.

N.J. Wall, J.A. Spittle, and R.D. Jones: Proc. 1st Int. Conf. on Zinc Coated Steel Sheet, Munich, June 1985, Zinc Development Association, London, 1985, pp. C1-C6.

J.A. Spittle and S.G.R. Brown: INTERGALVA ’91 Proc. 3rd Int. Zinc Coated Sheet Conf., Barcelona, 1991, European General Galvanizers Association, London, 1991, pp. S4K/1-S4K/9.

Handbook of Chemistry and Physics, 62nd ed., CRC Press Inc., Boca Raton, FL, 1981–82.

S. Kavesh: in Principles of Fabrication, Rapid Solidification Technology—Source Book, R.L. Ashbrook, ed., ASM, Metals Park, OH, 1983, p. 83.

M.C. Flemings: Solidification Processing, McGraw-Hill Book Co., New York, NY, 1974, pp. 146–54 and pp. 290–94.

Metallographic Atlas of Zinc and Zinc Alloys, Centre de Recherches Métallurgique, Liege, Belgium, 1981, p. 2.7.24.

Nai-Yong Tang and G.R. Adams: Proc., The Physical Metallurgy of Zinc Coated Steel, TMS Annual Meeting, San Francisco, CA, A.R. Marder, ed., TMS, Warrendale, PA, 1994, pp. 41–54.

Yong-Wu Kim and R.S. Patil: Proc. Ist Int. Conf. on Zinc Coated Steel Sheet, Munich, June 1985, Zinc Development Association, London, 1985, pp. D1-D5.

W. Kurz and D.J. Fischer: Fundamentals of Solidification, 3rd ed., Trans Tech Publications Ltd., Aedermannsdorf, Switzerland, 1989, pp. 63–89.

G.E. Nash and M.E. Glicksman: Acta Metall., 1974, vol. 22, p. 1291.

J. Faderl, W. Maschek, and J. Strutzenberger: Proc. of GALVATECH ’95, Chicago, IL, 1995, Iron and Steel Society Inc., Warrendale, PA, 1995, pp. 675–85.

J.D. Verhoeven: Fundamentals of Physical Metallurgy, John Wiley & Sons, New York, NY, 1975.

W.J. Moore and D.O. Hummel: Physikalische Chemie, 3rd ed., Walter de Gruyter & Co, Berlin, 1983, p. 191.

Gmelins Handbuch der Anorganischen Chemie, System Nummer 32, Zink Ergänzungsband, 8th ed., Verlag Chemie GmbH., Weinheim/Bergstraße, 1956, pp. 347–48.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Strutzenberger, J., Faderl, J. Solidification and spangle formation of hot-dip-galvanized zinc coatings. Metall Mater Trans A 29, 631–646 (1998). https://doi.org/10.1007/s11661-998-0144-8

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-998-0144-8