Abstract

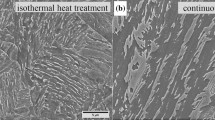

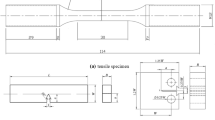

In the present study, the crack opening displacement (COD) tests of specimens of C-Mn base and weld steel were carried out in the ductile-brittle transition temperature region. The majority of the specimens were fractured and others were unloaded prior to fracture after ductile fracture initiated and extended. The cavities and cleavage microcracks located in the vicinities of tips of fibrous cracks of the unloaded specimens were observed in detail. The finite element method (FEM) calculations of the stress and strain distribution ahead of the tip of an extending fibrous crack were completed. The mechanism of the ductile-to-brittle fracture transition was further investigated. It was revealed that in the ductile-brittle transition temperature region, the ductile fracture process was independent of temperature. The ductile-to-brittle fracture transition was triggered by initiating a catastrophic extension of a cleavage crack ahead of the fibrous crack tip, which occurred in a condition satisfying a combined criterion composed of three items, i.e., ε p ≥ ε pc for initiating a crack nucleus; σ m √σ ≥ T c for preventing the crack nucleus from blunting; and σ yy ≥ σ f for propagating the crack nucleus. For a specimen in which a fibrous crack occurred and propagated, the critical event for initiating a brittle cleavage fracture was the propagation of a ferrite grain-sized crack into neighboring grains. With extension of a fibrous crack, the behavior of the ductile-to-brittle fracture transition could be analyzed by the effect of the size of an “active zone” on the initiation of the brittle cleavage fracture.

Similar content being viewed by others

References

T. Iwadate, Y. Tanaka, S. Ono, and J. Watanabe: in Elastic-Plastic Fracture: 2nd Symp., Volume II—Fracture Resistance Curves and Engineering Applications, ASTM STP 803, C.F. Shih and J.P. Gudas, eds., ASTM, Philadelphia, PA, 1983, pp. II-531–II-61.

A.R. Rosenfield, and D.K. Shetty: Eng. Fract. Mech., 1983, vol. 17, pp. 461–70.

M.T. Miglin, C.S. Wade, and W.A. Van Der Sluys: in Fracture Mechanics: 21st Symp., ASTM STP 1074, J.P. Gudas, J.A. Joyce, and E.M. Hackett, eds., ASTM, Philadelphia, PA, 1990, pp. 238–63.

A.R. Rosenfield, D.K. Shetty, and A.J. Skidmore: Metall. Trans. A, 1983, vol. 14A, pp. 1934–37.

I. Milne and G.G. Chell: in Elastic-Plastic Fracture, ASTM STP 668, J.D. Landes, J.A. Begley, and G.A. Clarke, eds., ASTM, Philadelphia, PA, 1979, p. 1358.

F. Ebrahimi: Fracture Mechanics: 18th Symp., ASTM STP 945, D.T. Read, ed., ASTM, Philadelphia, PA, 1988, pp. 555–80.

I. Milne, D.A. Curry, and G.G. Chell: Elastic-Plastic Fracture, ASTM STP 668, J.D. Landes, J.A. Begley and G.A. Clarke, eds., ASTM, Philadelphia, PA, 1979, p. 586.

K. Satoh, M. Toyota, and M. Tsukamoto: Trans. Jpn. Weld. Soc., 1987, vol. 18, p. 54.

A. Bruckner: Advances in Probabistic Fracture Mechanics, D. Francois, ed., Pergamon, New York, NY, 1984, vol. 92, p. 105.

K. Wallin: Eng. Fract. Mech., 1989, vol. 32, p. 523.

J.H. Chen and G.Z. Wang: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 1381–90.

J.H. Chen, H. Ma, and G.Z. Wang: Metall. Trans. A, 1990, vol. 21A, pp. 513–20.

P.C. Paris, H. Tada, A. Zahoor, and H. Ernst: Elastic-Plastic Fracture, ASTM STP 668, J.D. Landes, J.A. Begley, and G.A. Clarke, eds., ASTM, Philadelphia, PA, 1979, p. 5.

D.K. Biswas, M. Venkatraman, C.S. Narendranath, and U.K. Chatterjee: Metall. Trans. A, 1992, vol. 23A, pp. 1479–92.

D. Kwon and R.J. Asaro: Metall. Trans. A, 1990, vol. 21A, pp. 117–34.

G.T. Hahn: Metall. Trans. A, 1984, vol. 15A, pp. 947–59.

S.K. Maiti and P.D. Savla: Eng. Fract. Mech., 1993, vol. 44, pp. 721–33.

M.F. Kanninen and E.F. Rybicki: Elastic-Plastic Fracture, ASTM STP 668, J.D. Landes, J.A. Begley, and G.A. Clarke, eds., ASTM, Philadelphia, PA, 1979, pp. 121–50.

H.G. Pisarski: Int. J. Fract., 1981, vol. 17, p. 427.

R.O. Ritchie, J.F. Knott, and J.R. Rice: J. Mech. Phys. Solids, 1973, vol. 21, p. 395.

E. Smith: Physical Basis of Yield and Fracture, Proc. Conf., Institute of Physics and Physical Society, Oxford, United Kingdom, 1966, p. 36.

J.H. Chen and G.Z. Wang: Metall. Trans. A, 1992, vol. 23A, pp. 509–17.

J.H. Chen, C. Yan, and J. Sun: Acta Metall. Mater., 1994, vol. 42, pp. 251–61.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Wang, G.Z., Chen, J.H. & Li, Z.H. Further study on the mechanism of the ductile-to-brittle fracture transition in C-Mn base and weld steel. Metall Mater Trans A 28, 1689–1698 (1997). https://doi.org/10.1007/s11661-997-0260-x

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-997-0260-x