Abstract

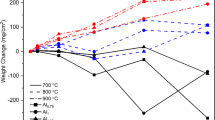

This article describes the effect of phosphorus on the microstructure and stress rupture property at 650 °C in an Fe-Ni-Cr base superalloy. The results showed that phosphorus markedly improved the intergranular precipitation in the range of 0.0005 to 0.016 wt pct, which facilitated M23C6 and M3B2 precipitation but inhibited the formation of MC carbide. A too high phosphorus addition (0.051 wt pct P) resulted in an excessive precipitation at grain boundaries, while a too low phosphorus content (0.0005 wt pct P) led to many precipitate-free grain boundaries. Phosphorus also enlarged the size of the γ′ particles and lowered its stability, that η-Ni3Ti preferred to form in the alloy with 0.051 wt pct P. Due to the improvement of the microstructure, appropriate amount of P content significantly prolonged the rupture life of the alloys in the range of 0.0005 to 0.016 wt pct. The peak value was 660 hours at 0.016 wt pct, more than 4 times that of the alloy with 0.0005 wt pct phosphorus, but phosphorus reduced the fracture elongation. The mechanism by which phosphorus influenced the alloy is discussed.

Similar content being viewed by others

References

G.W. Meetham: Met. Technol., 1984, vol. 11, pp. 414–18.

A.C. Wang, Y.Y. Li, C.G. Fan, K. Yang, D.F. Li, X. Zhao, and C.X. Shi: Scripta Metall. Mater., 1994, vol. 31, pp. 1695–1700.

Y.X. Zhu, S. Zhang, T. Zhang, L. Lou, Y. Tong, X. Ning, Z. Hu, and X. Xie: in Superalloys 718, 625, 706 and Various Derivatives, E.A. Loria, ed., TMS-AIME, Warrendale, PA, 1994, pp. 89–98.

W.R. Sun, S.R. Guo, J.T. Guo, D.Z. Lu, and Z.Q. Hu: Acta Metall. Sinica 1995, vol. 31A, pp. 346–50 (in Chinese).

C. Chen, R.G. Thompson, and D.W. Davis: in Superalloys 718, 625 and Various Derivatives, E.A. Loria, ed., TMS-AIME, Warrendale, PA, 1991, pp. 81–96.

John D. Verhoeven: Fundamentals of Physical Metallurgy, John Wiley & Sons, New York, NY, 1975, pp. 199–201.

J.T. Wang, Q. Chen, and G.S. Li: Acta Metall. Sinica, 1985, vol. 21A, pp. 477–84 (in Chinese).

B.R. Clark and F.B. Pickering: J. Iron Steel Inst., 1967, Jan., pp. 70–84.

J. Nutting: Structural Process in Creep, 1961, p. 149.

D. Bika and C.J. McMahon: Acta Metall. Mater., 1995, vol. 43, pp. 1909–16.

S.-H. Chen, T. Takasugi, and D.P. Pope: Scripta Metall. Mater., 1982, vol. 16, pp. 79–83.

P.E. Li, J.S. Zhang, F.G. Wang, and J.Z. Jin: Metall. Trans. A, 1992, vol. 23A, pp. 1379–81.

A.J. Perry: J. Mater. Sci., 1974, vol. 9, pp. 1016–44.

W.R. Sun, S.R. Guo, D.Z. Lu, J.T. Guo, and Z.Q. Hu: Acta Metall. Sinica, 1995, suppl., vol. 31, pp. 112–15 (in Chinese).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sun, W.R., Guo, S.R., Lu, D.Z. et al. Effect of phosphorus on the microstructure and stress rupture properties in an Fe-Ni-Cr base superalloy. Metall Mater Trans A 28, 649–654 (1997). https://doi.org/10.1007/s11661-997-0050-5

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-997-0050-5