Abstract

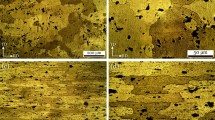

By making effective use of precipitation hardening of AA3004 alloys, a superstrengthening effect was achieved in the manufacturing of AA3004 can stock materials through modified processing, which combines a regular work hardening process with a further precipitation hardening process. The annealing operation in the conventional processing was replaced by a high-temperature solution treatment to regain a high supersaturation of solutes in solid solution. The combined operations of cold rolling and low-temperature aging were able to yield varied combinations of high mechanical strength and ductility. In this work, the effects of processing sequences on the mechanical property improvement and the texture control of the final gage sheets were studied. The mechanical properties of the materials were evaluated based on the tensile results. Texture analyses were performed by means of orientation distribution function (ODF) descriptions. Earing tests were carried out in order to determine the mechanical anisotropy of the final sheets.

Similar content being viewed by others

References

S. Ding: Ph.D. Thesis, University of Kentucky, Lexington, KY, 1996, pp. 58–83.

E. Usui, T. Inaba, and N. Shinano: Kobelco Technol. Rev., 1990, vol. 7, pp. 14–17.

a. Ruhenbeck: Aluminium, 1953, vol. 29, pp. 254–55.

W.A. Anderson: in Precipitation from Solid Solution, R.F. Mehl et al., eds., ASM, Cleveland, OH, 1959, pp. 150–207.

D.J. Lloyd and D. Kenny: Metall. Trans. A, 1982, vol. 13A, pp. 1445–52.

Hsun Hu, R.S. Cline, and S.R. Goodman: Recrystallization, Grain Growth and Textures, ASM, Metals Park, OH, 1966, pp. 295–366.

John E. Hatch: Aluminum—Properties and Physical Metallurgy, ASM, Metals Park, OH, 1984, pp. 124–25.

I.L. Dillamore and H. Katoh: Met. Sci., 1974, vol. 8, pp. 73–83.

J. Hjelen, R. Orsund, and E. Nes: Acta Metall., 1991, vol. 39, pp. 1377–1404.

K. Lucke and O. Engler: Mater. Sci. Technol., 1990, vol. 6, pp. 1113–30.

A.L. Dons and E. Nes: Mater. Sci. Technol., 1986, vol. 2, pp. 8–18.

J. Hirsch and K. Lucke: Acta Metall., 1988, vol. 36, pp. 2863–82.

K. Lucke, C. Darmann, and J. Hirsch: Trans. Ind. Inst. Metall., 1985, vol. 38, pp. 496–509.

K. Lucke and J. Hirsch: Proc. Aluminum Technology 86, T. Sheppard, ed., The Institute of Metals, London, 1986, pp. 267–79.

B.J. Duggan, M. Hatherly, W.B. Hutchinson, and P.T. Wakefield: Met. Sci., 1978, vol. 12, pp. 343–51.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Ding, S., Morris, J.G. Processing of AA3004 alloy can stock for optimum strength and formability. Metall Mater Trans A 28, 2715–2721 (1997). https://doi.org/10.1007/s11661-997-0028-3

Issue Date:

DOI: https://doi.org/10.1007/s11661-997-0028-3