Abstract

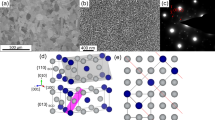

The Immm-Ni2(Cr,Mo,W) body centered orthorhombic (BCO) intermetallic phase, denoted as γ′″, is the primary strengthening phase in commercial Ni-base HAYNES® 242® and 244® alloys. Due to the relatively low symmetry and six crystallographic variants precipitating in the face-centered cubic solid solution γ matrix, the deformation mechanisms are expected to be complex, and a myriad of planar defects are predicted to be observed on the close-packed {013} and {110} planes, which are nearly co-planar to the matrix {111} plane. We find that these defects include those analogous to the γ′-Ni3Al phase: superlattice intrinsic stacking faults, antiphase boundaries, and complex stacking faults. We determined these planar defect energies and generalized stacking fault energy surfaces utilizing ab initio density functional theory calculations. The γ′″ {013} and {110} planes exhibited comparable planar defect energies but showed drastically different dislocation shear pathways due to the lower symmetry of the orthorhombic phase. We observed that the addition of W increased the fault energies significantly, which could correspond to the observed increase in yield strength of 244 alloy over that of 242 alloy.

Similar content being viewed by others

References

R.C. Reed: The Superalloys Fundamentals and Applications, 2006.

T.M. Pollock and S. Tin: J. Propul. Power, 2006, vol. 22, pp. 361–74.

R.E. Schafrik and R. Sprague: Advanced Materials and Processes.

R.C. Reed and R.C. Reed: The Physical Metallurgy of Nickel and Its Alloys, 2009.

M.G. Fahrmann, S.K. Srivastava, and L.M. Pike: MATEC Web of Conferences, https://doi.org/10.1051/matecconf/20141417004.

P.E.A. Turchi, L. Kaufman, and Z.K. Liu: Calphad, 2006, vol. 30, pp. 70–87.

Y. Mishin: Acta Mater., 2004, vol. 52, pp. 1451–67.

D.C. Lv, D. McAllister, M.J. Mills, and Y. Wang: Acta Mater., 2016, vol. 118, pp. 350–61.

L. Feng, D. Mcallister, C.H. Zenk, M.J. Mills, and Y. Wang: Deformation Mechanisms of γ ′ and γ ” Co -Precipitates in IN718, Springer International Publishing, 2020.

L. Kovarik, R.R. Unocic, J. Li, P. Sarosi, C. Shen, Y. Wang, and M.J. Mills: Prog. Mater. Sci., 2009, vol. 54, p. 54.

R.W. Kozar, A. Suzuki, W.W. Milligan, J.J. Schirra, M.F. Savage, and T.M. Pollock: Metall. Mater. Trans. A, 2009, vol. 40A, pp. 1588–1603.

Q.Z. Chen and D.M. Knowles: Mater. Sci. Eng. A, 2003, vol. 356, pp. 352–67.

D. Caillard, G. Molénat, and V. Paidar: Mater. Sci. Eng. A, 1997, vol. 234, pp. 695–98.

M.S. Titus, Y.M. Eggeler, A. Suzuki, and T.M. Pollock: Acta Mater., 2015, vol. 82, pp. 530–39.

T.M. Smith, R.R. Unocic, H. Deutchman, and M.J. Mills: Mater. High Temp., 2016, vol. 33, pp. 372–83.

B.H. Kear and H.G.F. Wilsdorf: Transactions of The American Institute of Mining, Metallurgical and Petroleum Engineers.

R. (Nasa L.R.C. Bowman: 9th International Symposium on Superalloys.

J.S. van Sluytman, C.J. Moceri, and T.M. Pollock: Mater. Sci. Eng. A, 2015, vol. 639, pp. 747–54.

M. Khantha, V. Vitek, and D.P. Pope: Modell. Simul. Mater. Sci. Eng., 1994, vol. 2, pp. 587–96.

G. Sauthoff: Intermetallics, 2007.

N. Yang, Y. Wei, C. Song, and L. Jiao: Acta Metall. Sin., 1986, vol. 22, pp. 477–83.

M. Dodaran, A.H. Ettefagh, S.M. Guo, M.M. Khonsari, W.J. Meng, N. Shamsaei, and S. Shao: Intermetallics (Barking), 2020, vol. 117, 106670.

D. Baither, C. Rentenberger, H.P. Karnthaler, and E. Nembach: Philos. Mag. A, 2002, vol. 82, pp. 1795–1805.

G. Molenat and D. Caillard: Philos. Mag. A, 1991, vol. 64, pp. 1291–1317.

W. Cai and W.D. Nix: Imperfections in Crystalline Solids, 2016.

Y. Rao, T.M. Smith, M.J. Mills, and M. Ghazisaeidi: Acta Mater., 2018, vol. 148, pp. 173–84.

T.M. Smith, B.D. Esser, N. Antolin, G.B. Viswanathan, T. Hanlon, A. Wessman, D. Mourer, W. Windl, D.W. McComb, and M.J. Mills: Acta Mater., 2015, vol. 100, pp. 19–31.

A. Mottura, A. Janotti, and T.M. Pollock: Intermetallics (Barking), 2012, vol. 28, pp. 138–43.

M. Kumar and V.K. Vasudevan: Acta Mater., 1996, vol. 44, pp. 4865–80.

M. Kumar and V.K. Vasudevan: Acta Mater., 1997, vol. 45, pp. 3203–22.

D.G. Pettifor Cottrell Alan Institute of Materials (London England): Electron Theory in Alloy Design, Institute of Materials, London, 1992.

H. Hasan, P. Mlkvik, P.D. Haynes, and V.A. Vorontsov: Materialia (Oxford), 2020, vol. 9, 100555.

G. Kresse and J. Hafner: Phys. Rev. B, 1993, vol. 48, pp. 13115–18.

G. McCartney, T. Hacker, and B. Yang: Educause Review.

P.E. Blöchl: Phys. Rev. B, 1994, vol. 50, pp. 17953–79.

G. Kresse and D. Joubert: Phys. Rev. B, 1999, vol. 59, pp. 1758–75.

G. Kresse and J. Furthmüller: Comput. Mater. Sci., 1996, vol. 6, pp. 15–50.

G. Kresse and J. Furthmüller: Phys. Rev. B, 1996, vol. 54, pp. 11169–86.

R. Hu, G.M. Cheng, J.Q. Zhang, J.S. Li, T.B. Zhang, and H.Z. Fu: Intermetallics (Barking), 2013, vol. 33, pp. 60–66.

V. Vitek: Prog. Mater Sci., 1992, vol. 36, pp. 1–27.

S. Zhao, G.M. Stocks, and Y. Zhang: Acta Mater., 2017, vol. 134, pp. 334–45.

T.L. Achmad, W. Fu, H. Chen, C. Zhang, and Z.G. Yang: Comput. Mater. Sci., 2016, vol. 121, pp. 86–96.

M. Kanani, A. Hartmaier, and R. Janisch: Acta Mater., 2016, vol. 106, pp. 208–18.

A.R. Natarajan and A. van der Ven: Npj Comput. Mater., 2020, vol. 6, pp. 80–89.

P. Vinet, J. Ferrantef, J.R. Smith, and J.H. Rose: J. Phys. C, 2022, https://doi.org/10.1088/0022-3719/19/20/001.

J.H. Rose, J. Ferrante, and J.R. Smith: Phys. Rev. Lett., 1981, vol. 47, pp. 675–78.

A. Jain, G. Hautier, C.J. Moore, S. Ping Ong, C.C. Fischer, T. Mueller, K.A. Persson, and G. Ceder: Comput. Mater. Sci., 2011, vol. 50, pp. 2295–2310.

K.S. Chan, Y.D. Lee, and Y.M. Pan: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 523–37.

K.V. Vamsi and S. Karthikeyan: Superalloys, 2012, vol. 3, pp. 521–30.

K. v. Vamsi and S. Karthikeyan: MATEC Web of Conferences, 2014, vol. 14, pp. 1–6.

J. Kim: J. Alloy. Compd., 2015, vol. 650, pp. 564–71.

A. Zunger, S.H. Wei, L.G. Ferreira, and J.E. Bernard: Phys. Rev. Lett., 1990, vol. 65, pp. 353–56.

J.M. Sanchez: Phys. Rev. B, 1993, vol. 48, pp. 14013–15.

P. Srimannarayana, K. V. Vamsi, and S. Karthikeyan: MATEC Web of Conferences, https://doi.org/10.1051/matecconf/20141415003.

J.B. Singh, M. Sundararaman, and P. Mukhopadhyay: Philos. Mag. A, 2000, vol. 80, pp. 1983–2010.

W. Cai, V. v. Bulatov, J. Chang, J. Li, and S. Yip: in Dislocations in Solids, 2004.

J. Wang, H. Sehitoglu, and H.J. Maier: Int. J. Plast, 2014, vol. 54, pp. 247–66.

B. Joos and Q. Ren: Phys. Rev. B, 1994, vol. 50, pp. 5890–98.

B. Joós and M.S. Duesbery: Phys. Rev. Lett., 1997, vol. 78, pp. 266–69.

G. Schoeck: Mater. Sci. Eng. A, 2005, vol. 400–401, pp. 7–17.

T.M. Pollock and A.S. Argon: Acta Metall. Mater., 1992, vol. 40, pp. 1–30.

D. Hull and D.J. Bacon: Introduction to Dislocations, vol. 5, 2011.

J.P. Hirth, J. Lothe, and T. Mura: Theory of Dislocations (2nd Ed.), 1983.

P. Chowdhury, H. Sehitoglu, W. Abuzaid, and H.J. Maier: Int. J. Plast, 2015, vol. 71, pp. 32–61.

S. Mahajan and G.Y. Chin: Acta Metall., 1973, vol. 21, pp. 1353–63.

Y.M. Juan and E. Kaxiras: Philos. Mag. A, 1996, vol. 74, pp. 1367–84.

J. Wang and H. Sehitoglu: Intermetallics (Barking), 2014, vol. 52, pp. 20–31.

V. Paidar, D.P. Pope, and V. Vitek: Acta Metall., 1984, vol. 32, pp. 435–48.

V. Vitek: Intermetallics (Barking), 1998, vol. 6, pp. 579–85.

M. Yamaguchi, V. Paidar, D.P. Pope, and V. Vitek: Philos. Mag. A, 1982, vol. 45, pp. 867–82.

Acknowledgments

This work was supported by a generous gift from Haynes International, Inc., and through computational resources provided by Information Technology at Purdue University, West Lafayette, Indiana. TM would like to thank Dr. Dongsheng Wen and Dr. Shivam Tripathi for their vital help and guidance.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

See Table AI.

Appendix B

The equilibrium separation distance of partial dislocations can be calculated by a force balance between the Peach-Koehler forces of the dislocations, and the force from the energy of the planar defect bound by the partials. The following equation was used to determine these distances.

\(F\left({\gamma }_{defect}\right)\) is the attractive force that minimizes the faulted region, and \(F\left(K, {d}_{i}\right)\) is the repulsive force between the partial dislocations. K is \(\frac{\mu {b}^{2}}{2\pi }\) where μ is the shear modulus of the system and b is the burgers vector of the partial dislocations. The magnitude of the partial dislocation burgers vector depends on the b lattice parameter shown in Table II. The shear modulus for each system and each plane is extracted from the elastic tensor determined using the VASP software for the super cell. The separations distances are shown in Table BI. The coefficients used to analytically represent the slip pathway we calculated and are shown in Table BII. The disregistry function and misfit energy curves for the Ni2Mo and Ni2W system are shown in Figures B1 and B2. These systems are like the Ni2Cr, but the different energies of the various planar defects and different shear moduli affect the equilibrium separation in the disregistry function and the curvature of the misfit energy. The equilibrium separation distance is determined by solving the following systems of equations for each plane and direction (see Table BIII).

{013} Short: \({\gamma }_{isf}=K\left(\frac{1}{{d}_{1}}\right)\)

{013} Full:

{110} Full:

The disregistry functions and misfit energy curves for the Ni2Cr system. (a) Shows the disregistry function for the easy slip pathway of the {013}γ′″ plane and the misfit energy is shown in (b). The equilibrium separation distance of the partial dislocations is also shown. (c) And (e) show the disregistry function for the whole pathway along the {013} γ′″ and {110} γ′″ planes respectively, and (d) and (f) show the misfit energy curves used to determine the Peierls Stress

The disregistry functions and misfit energy curves for the Ni2Cr system. (a) Shows the disregistry function for the easy slip pathway of the {013}γ′″ plane and the misfit energy is shown in (b). The equilibrium separation distance of the partial dislocations is also shown. (c) And (e) show the disregistry function for the whole pathway along the {013} γ′″ and {110} γ′″ planes respectively, and (d) and (f) show the misfit energy curves used to determine the Peierls Stress

Rights and permissions

About this article

Cite this article

Mann, T., Fahrmann, M.G. & Titus, M.S. Ab Initio Investigation of Planar Defects in Immm-Ni2(Cr,Mo,W) Strengthened HAYNES 244 Alloy. Metall Mater Trans A 53, 4188–4206 (2022). https://doi.org/10.1007/s11661-022-06797-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06797-w