Abstract

The dependence of stacking fault energy (\({\gamma }_{\text{SFE}}\)) on temperature in austenitic Fe–Cr–Ni alloy powders was investigated by in situ high energy synchrotron X-ray diffraction and ab initio calculations in the temperature range from − 45 °C to 450 °C. The X-ray diffraction peak positions were used to determine the stacking fault probability and subsequently the temperature dependence of γSFE. The effect of temperature on the diffraction peak positions was found to be mainly reversible; however, recovery of dislocations occurred above about 200 °C, which also gave an irreversible contribution. Two different ab initio-based models were evaluated with respect to the experimental data. The different predictions of the models can be explained by their respective treatment of the magnetic moments for Cr and Ni, which is critical for the alloy compositions investigated. Ab initio calculations, taking longitudinal spin fluctuations (LSF) into consideration within the quasi-classical phenomenological model, predict a temperature dependence of \({\gamma }_{\rm SFE}\) in good agreement with the experimentally evaluated trend of increasing γSFE with increasing temperature: \(\left|\Updelta {\gamma }_{\rm SFE}/\Updelta T\right|=0.05 {\text{mJ}} {\text{m}}^{-2}/{\text{K}}.\) The temperature effect on γSFE is similar for all three investigated alloys: Fe–18Cr–15Ni, Fe–18Cr–17Ni, Fe–21Cr–16Ni (wt pct), while their room temperature \({\gamma }_{\rm SFE}\) are evaluated to be 22, 25, 20 mJ m−2, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Plastic deformation of materials with the face-centered cubic (fcc) structure occurs by one of three possible mechanisms: deformation-induced martensitic transformation, twinning or dislocation glide.[1,2,3] The active deformation mechanism in the austenite phase critically controls the deformation properties of many advanced steels with the martensitic transformation being responsible for the transformation-induced plasticity (TRIP) effect, while twinning is responsible for the twinning-induced plasticity (TWIP) effect. Thus, the possibility to tune the deformation behavior of the austenite phase is critical in steel development. It is known that the stacking fault energy (\({\gamma }_{\rm SFE}\)), basically determining the width of stacking faults in fcc materials and thus the ease of cross-slip, etc., is a key parameter to control the deformation mechanism of austenite. Since the magnitude of \({\gamma }_{\rm SFE}\) depends among others, on the chemical composition of the alloy, deformation behavior can be tuned by adjusting the chemical composition. This indicates that it is highly desirable to understand the effect of alloying elements (individual and collective effects) on \({\gamma }_{\rm SFE}\). Another important effect on \({\gamma }_{\rm SFE}\) is the temperature effect. Since it is known that \({\gamma }_{\rm SFE}\) depends on the temperature. This becomes particularly important in forming operation and in service at elevated temperatures, which could potentially change the active deformation mechanism. In spite of its importance, the literature is still divergent on the temperature dependence of \({\gamma }_{\rm SFE}\) in important alloys.[4,5] Numerous studies have been performed to examine the effect of temperature on deformation behavior and microstructure of austenitic stainless steel alloys. These are deformed at various temperatures and the stress–strain behavior as well as the resulting deformation microstructure are investigated. Since the magnitude of \({\gamma }_{\rm SFE}\) is believed to control the deformation mechanism, the observed change of the deformation microstructure can be related to the magnitude of \({\gamma }_{\rm SFE}\).[3,6,7,8,9,10] These studies provide reliable indications of the temperature dependence of \({\gamma }_{\rm SFE}\), however, the effect of temperature on \({\gamma }_{\rm SFE}\) is only investigated indirectly. A different approach to study the temperature dependence of \({\gamma }_{\rm SFE}\) has been reported in References 11,12,13,14,15, through 16. In these studies, the influence of temperature on \({\gamma }_{\rm SFE}\) is observed directly by transmission electron microscopy (TEM). Changes in the size of triple nodes and stacking fault (SF) ribbons in thin-foil samples during heating and cooling are related to the temperature dependence of \({\gamma }_{\rm SFE}\) in a series of pure metals and metallic alloys. Despite the experimental difficulties, they concluded that \({\gamma }_{\rm SFE}\) increases with elevated temperature for austenitic stainless steels. Furthermore, the dislocation node size and thus the obtained magnitude of \({\gamma }_{\rm SFE}\) was to some extent reversible during the thermal cycling. However, the previously conducted experimental studies utilizing TEM have limitations. Besides being tedious in nature, the estimation of SFE in thin TEM foils additionally suffer from pronounced stress and strain relaxation effects.[17] Therefore, the TEM measurements could be well complemented by measurements on bulk materials, e.g., by high energy X-ray diffraction (HEXRD) or neutron diffraction measurements, wherein, the strain/stress relaxation effects are minimized. Such measurements should provide reliable calibration and validation data for the modeling of \({\gamma }_{\rm SFE}\). In the present work, we undertake an effort to evaluate the temperature dependence of \({\gamma }_{\rm SFE}\) in the bulk of austenitic stainless steel alloys. In situ synchrotron X-ray diffraction investigations of the temperature effect on the faulted area and \({\gamma }_{\rm SFE}\) in Fe–Cr–Ni alloys, the base alloy system for austenitic stainless steels, has been performed as presented in Reference 18 and compared with state-of-the-art ab initio calculations.

2 Methodology

2.1 Sample Preparation

The Fe–Cr–Ni alloys were produced by arc-melting in an inert Argon atmosphere. During this process the pure elements iron, chromium and nickel were melted together to a small ingot that weighed approximately 7 grams. Table I shows the realized chemical composition of the alloys. To homogenize the samples and to achieve a fully austenitic structure, the ingots were slightly deformed, vacuum sealed in quartz tubes and heat treated at 1100 °C for 12 hours prior to cooling in an argon stream to room temperature. After heat treatment, the samples were ground by hand with abrasive paper to produce filings. To control the particle size of the filings, the powder was sieved through a 150-mesh screen, which limits the size of the particle diameter to roughly 105 µm. The size was confirmed by light optical microscopy.

2.2 In Situ Synchrotron X-ray Diffraction Experiments and Data Analysis

The synchrotron X-ray diffraction experiments were performed at the high energy powder diffraction beamline P02.1 at PETRA III, Hamburg, Germany.[19] The energy of the used synchrotron radiation was 59.86 keV, i.e., λ = 0.20713 Å. The powder diffraction patterns were collected with a PerkinElmer XRD 1621 area detector. A Linkam furnace T95 was used for temperature control with the precision of 1 °C. Calibration measurements were conducted on a CeO2 powder. The diffraction patterns of the samples were collected in situ in the temperature ranges from 45 °C to 450 °C as well as from RT to – 45 °C. In the heating experiments the samples were heated up to 450 °C in approximately 45 °C steps, where each temperature step took around 7 minutes for ramping, thermal equilibration and data acquisition. Subsequently, the same samples were cooled down from 450 °C to room temperature, but in this case with temperature intervals of 90 °C, allowing each step to take around 10 minutes. Cryo-cooling experiments were conducted for fresh samples from both alloy A starting from room temperature and cooling down to − 13 °C and − 45 °C using liquid nitrogen cooling. Alloy A and B were only measured down to − 13 °C. The time in between each temperature step and therefore each recorded diffraction pattern during the cryo-cooling experiments was 8 minutes for ramping and thermal equilibration.

The calibration of detection conditions and the integration of the 2D raw data was performed utilizing fit2d v12.077.[20,21] The removal of the background and the fitting of the diffraction patterns were conducted using the software Line-Profile Analysis Software (LIPRAS),[22] where a second-order polynomial was fitted to the background and a pseudo-Voigt function to the diffraction peaks. The diffraction peaks were fitted individually to determine the absolute peak position and the lattice parameter via Bragg’s law. To ensure the accuracy of the fitting, the residuals expressed as \({R}_{\rm p}\) and \({R}_{\rm wp}\) were minimized during the fitting procedure.

2.3 X-ray Diffraction Determination of Stacking Fault Probability

The probability of finding a stacking fault (SF) on the {111} plane between any two layers is given by the stacking fault probability α. The presence of SFs changes the line profile of X-ray diffraction peaks. These changes are proportional to α and depend significantly on the h, k, and l of the reflection. α is commonly obtained by evaluating the shift of X-ray diffraction peaks in 2θ only.[23,24,25,26,27,28,29,30,31] The peak shift from its original position in 2θ (∆(2θ)) for an austenite reflection caused by α as derived by Warren[23] is given by

where \({\sum }_{b}\left(\pm \right)\frac{{L}_{0}}{{h}_{0}^{2}\left(u+b\right)}\) is a parameter given for each individual hkl reflection (see Supplementary material), in which \({{h}_{0}^{2}={(h}^{2}+{k}^{2}+{l}^{2})}^\frac{1}{2},\;{L}_{0}=h+k+l,\) and \((u+b)\) represent the total number of unbroadened and broadened component reflections and \(\theta \) is the diffraction angle.

Equation [1] shows, that the magnitude of the peak shift increases with increasing \(\alpha \). In the case of powders with random crystallographic orientation of particles, the diffraction peak positions are affected by the lattice spacing and SFs present in the filing only.[28] With this assumption equation [1] becomes:

where 2θhkl is the absolute peak position for a specific hkl. Using Eq. [2], \(\alpha \) can be determined from the absolute 2θ peak positions of the measured austenite X-ray diffraction peaks that are displaced by SFs. As suggested by Warren [23] α is calculated from the difference in peak positions of two neighboring peaks, preferably peaks displaced in opposite directions to reduce the effect of other sources that can lead to peak shift, e.g., diffractometer zero angle error. For the neighboring diffraction pair 200 to 220, Eq. [2] becomes:

The experimental diffraction peak positions and thus (2θ220−2θ200)meas in the in situ experiments performed are additionally affected by lattice expansion due to the changes in temperature. Therefore, the thermal expansion was subtracted from the measured peak positions calculated by \({a}_{\rm calc}={a}_{0}{\alpha }_{\rm CTE,C}\Updelta T,\) where \({a}_{\rm calc}\) is the determined lattice parameter at the elevated temperatures, \({\alpha }_{\rm CTE}\) is the coefficient of linear expansion, \({a}_{0}\) is the lattice parameter at room temperature, and \(\Updelta T\) is the difference in temperature.

The determination of \({\gamma }_{\rm SFE}\) from the X-ray diffraction data is given as[29]

where \({K}_{hkl}\) is a constant, \({G}_{hkl}\) is the shear modulus and \({\langle {\varepsilon }_{50}^{2}\rangle }_{hkl}\) is the squared microstrain, which is proportional to the dislocation density \(\rho \)[29] and \({a}_{0}\) the lattice parameter. By connecting the amount of SFs, which is proportional to the density of Shockley partial dislocations \(\rho \), with the average width w of the SFs, α can be expressed as[4,30,31]

Combining [4] and [5] results in

With the knowledge of \({G}_{hkl}\) and \({a}_{0}\) as a function of temperature, and assuming that \(\rho \) is constant at low temperatures, i.e., no dislocation annihilation occur, the temperature dependence of \({\gamma }_{\rm SFE}\) can be investigated by studying changes in \(\alpha \).

2.4 Ab Initio Calculations

Although austenitic Fe–Cr–Ni steels have been investigated for decades, an accurate description of their finite-temperature properties at the atomic and electronic structure levels is still a challenging task due to their non-trivial magnetism.[32,33] To model \({\gamma }_{\rm SFE}\) in austenitic steels, two state-of-the-art methodologies are applied here. The first one[33,34] was applied to calculate \({\gamma }_{\rm SFE}\) for the first time in Reference 9, but has not been applied to calculate it in a large temperature range; while the second one[35] has never been applied to calculate \({\gamma }_{\rm SFE}\) previously. This constitutes a density functional theory (DFT)-based approach that can be used for multicomponent alloys in the paramagnetic state, where the simultaneous effects of chemical and magnetic disorder on the electronic structure should be taken into consideration.[33] It should be noted that many-body finite-temperature simulations can provide a more accurate description[36]; however, these methods are still under development and are not yet widely used in the calculation of multicomponent austenitic steels.[37]

In this paper, the paramagnetic state of fcc Fe–Cr–Ni alloys has been modeled using the disorder local moment (DLM) model.[38] In its original formulation, it substitutes randomly oriented local magnetic moments by a collinear structure with randomly distributed spin-up and spin-down magnetic moments. It provides a quite accurate DFT description of systems with localized type of magnetism such as Fe in the paramagnetic state. Meanwhile, Ni and Cr exhibit weak itinerant magnetism; therefore, their local magnetic moments depend strongly on the local and global configurations of atomic magnetic moments and disappear in the DLM calculations.[33,39] In reality, however, their average local magnetic moments are finite due to longitudinal spin fluctuations (LSF) on short time scales.[40] This is a dynamical process as everything at finite temperature. Nevertheless, it can be modeled in the adiabatic approximation using some classical magnetic Hamiltonians containing longitudinal spin fluctuations (LSF).[33,34]

To calculate free energies of alloys, two models have been used to account for LSFs. In the first model, the LSF-1 model, the formalism for the LSFs has been used.[40] It is a classical high-temperature limit of the spin fluctuation theory,[41,42] in which the contribution due to the thermally induced spin fluctuations is considered within a phenomenological model based on a classical magnetic Hamiltonian. Although it breaks down at low temperatures, where quantum effects are important, it accounts for the LSFs at elevated temperatures.[33] A further simplification can be obtained for a specific form of the LSF energy: the entropy of longitudinal spin fluctuations in the disordered local moment state has been evaluated in the classical high-temperature limit for the quadratic form of the longitudinal spin fluctuations energy.[33,34] Although the LSF energy of Ni and Cr in these alloys is not exactly a quadratic function, a parabolic form of their LSF energy provides a good support for using this analytical model.[33] In the second model, the LSF-2 model, the entropy of longitudinal spin fluctuations has been used in the expression, which was derived for the integration measure in the configuration space of the extended classical Heisenberg Hamiltonian with longitudinal variations of spin moment magnitudes.[35,43] Note that this model can only be applied for the paramagnetic state at high temperatures, e.g., RT. Further, using these expressions for the magnetic entropy, the average local magnetic moments at a given temperature have been obtained in DFT self-consistent calculations.[33]

The \({\gamma }_{\rm SFE}\) was calculated using the axial next-nearest-neighbor Ising (ANNNI) model[44]:

where Fhcp(dhcp, fcc)(T) are the free energies of the ideal hexagonal close packed (hcp, …ABAB….-type stacking), double hcp (dhcp, …ABACABAC…-type stacking) , and face-centered cubic (fcc, …ABCABC…-type stacking) structures.[45,46] The volume per atom of the ideal hcp and dhcp structures is the same as for the fcc structure, implying that only the fcc volume needs to be known, which was determined from the lattice parameter for the alloys under consideration measured by X-ray diffraction. The ANNNI model accounts for the interactions between the next-nearest-neighbor stacking planes and has been shown to be a reasonable choice in terms of accuracy and computational cost for ab initio calculations for Fe-based fcc alloys.[47,48] The self-consistent density functional theory total energy calculations were performed by the exact muffin-tin orbital method (EMTO) combined with the coherent potential approximation (CPA) to treat the electronic structure of random atomic configurations.[49,50]

The one-electron thermal excitations were included using the Fermi–Dirac distribution function.[51] The alloys’ free energies were determined as described in Reference 52. The total energies were calculated in the generalized gradient approximation.[53] All the self-consistent EMTO-CPA calculations were performed for the orbital momentum cut-off of \({l}_{\rm max}= 3\) for the partial waves. The integration over the Brillouin zone was performed using a grid of 31 × 31 × 31, 31 × 31 × 19 and 31 × 31 × 9 k-points determined according to the Monkhorst-Pack scheme for fcc, hcp, and dhcp respectively.[54].

The accuracy of the CPA was evaluated by corresponding locally self-consistent Green’s function calculations (LSGF).[55,56] The EMTO-LSGF method has also been used to determine the parameters (on-site screening constants αscr and βscr) describing the contributions of screened Coulomb interactions to the one-electron potential of an alloy component and to the total energy within the single-site formalism.[57,58] The calculated on-site screening constants αscr vary with the structure and little with the alloy composition, lattice parameters and temperature. For the fcc structure, they are equal to 0.725, 0.777 and 0.824 for Fe, Cr and Ni, respectively, while βscr is about 1.14.[9]

3 Results and Discussion

3.1 X-ray Diffraction Results and Stacking Fault Probability

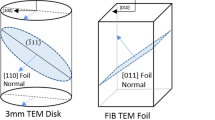

Figure 1 shows the measured lattice parameter \({a}_{\rm meas}^{111}\), \({a}_{\rm meas}^{200}\) and \({a}_{\rm meas}^{220}\) determined for material C during heating in the temperature range from 45 °C to 450 °C and during cryo-cooling down to − 45 °C. Also included in Figure 1 and represented by the black line is the linear thermal expansion of the lattice parameter aLTE with a coefficient of thermal expansion of \({\alpha }_{\rm CTE,C}=18.5\cdot {10}^{-6}{ K}^{-1}\). It can be seen that all measured lattice parameter differ significantly from aLTE for all temperatures, with a larger deviation at low temperatures than at higher temperatures. The measured lattice parameter deviations can be explained by the presence of SFs and their effect on the diffraction peak position as discussed in chapter 2.3. This is convincingly shown in Figure 2 for 111, 200 and 220. The plotted diffraction patterns are simulated with the aid of the software Diamond.[59] A perfect fcc stacking is generated from which a powder diffraction pattern can be predicted. By introducing a range of stacking fault probabilities into the fcc stacking the effect of SFs on the simulated diffraction peak positions can be studied. It can be seen that, both the 111 and 220 austenite peak shift to larger 2θ angles, whereas 200 shifts to smaller angles. The simulated peak shifts are in agreement with the suggested values of \({\sum }_{b}(\pm )\frac{{L}_{0}}{{h}_{0}^{2}(u+b)}\) (see electronic supplementary Table S1) and supports the observations in Figure 1. Since \({\sum }_{b}(\pm )\frac{{L}_{0}}{{h}_{0}^{2}(u+b)}\) has a value of \(-1/2\) for 200, it shifts to lower 2θ angles with the presence of SFs causing a larger measured lattice parameter compared to the same material without SFs. On the contrary, 220 and 111 shift in the opposite direction by half the magnitude, with a magnitude of \(+\frac{1}{4}\) for \({\sum }_{b}(\pm )\frac{{L}_{0}}{{h}_{0}^{2}(u+b)}\), resulting in a smaller measured lattice parameter.

Calculated lattice parameter \({a}_{\rm LTE}\) and measured lattice parameters of the alloy C observed during the heating and cryo-cooling. The measured lattice parameters are determined from the 111, 200 and 220 reflections. The experimental error of the lattice parameter is \(\left|\Updelta a\right|<{10}^{-3}\,\AA \)

Peak positions of a perfect fcc lattice in the bottom of the graph and the peak shift with increasing amounts of stacking faults toward the top of the graph. Simulations were performed using the software Diamond.[59]

To determine α, the approach developed by Reed and Schramm 27 (see Eq. [1]) is applied. In the following, the difference in peak position is determined from the diffraction peaks 200 and 220, since the experimental accuracy for this pair of reflections is slightly higher than for 111 and 200. In Figure 3, the difference between \({a}_{\rm meas}^{200}\) and \({a}_{\rm meas}^{220}\) (\({\Updelta a}_{\rm meas}^{200{-}220}\)) is plotted vs temperature for the alloys A represented by stars, B circles and C crosses, respectively. The heating is represented by red markers and the subsequent cooling by blue markers, and finally the cryo-cooling is represented by orange markers. It can be seen, that \(\Updelta {a}_{\rm meas}^{200{-}220}\) decreases linearly with increasing temperature for all studied alloys. Considering Eqs. [3] and [5], the decrease in \(\Updelta {a}_{\rm meas}^{200{-}220}\) indicates that the total volume of faulted layers present in the sample decrease with increasing temperature, since the effect of SFs on the diffraction peaks decreases. \(\Updelta {a}_{\rm meas}^{200{-}220}\) determined during the subsequent cooling from 450 °C to 83 °C is shown in Figure 3. As the temperature decreases, \({\Updelta a}_{\rm meas}^{200{-}220}\) is observed to increase below about 250 °C for both A and C, and below 350 °C for B. This indicates that the faulted volume gets partly restored during the cooling of the sample. This is convincingly shown during the cryo-cooling at temperatures below RT for a powder that had not been heated or cooled before (see Figure 3). The decrease in temperature causes an expansion of the total faulted layers, which become visible as larger \(\Updelta {a}_{\rm meas}^{200-220}\).

By utilizing Eq. [3], the observed changes in peak position can be expressed as a change in α (see Section II–C), with consideration of the thermal lattice expansion. The determined values are plotted in Figure 4. \(\alpha \) during heating from 45 °C to 450 °C and subsequent cooling from 450 °C to 83 °C are indicated by red and blue markers, respectively, and during cryo-cooling by orange markers. The trend during heating is similar for all three alloys. α decreases from roughly 16 × 10−3 at 45 °C almost linearly down to 7 × 10−3 at 450 °C. The behavior was found to be partly reversible during the subsequent cooling where the SFs present in the steel show a significant expansion controlled by the temperature dependence of \({\gamma }_{\rm SFE}\) that can be observed as an increase in α. However, while subsequently cooling down to 83 °C, α does not reach the same magnitude as before heating. This suggests that recovery of the material during heating occurred, leading to annihilation of SFs and thus decreasing the total faulted volume. The delayed increase in α to about 250 °C for A and C, and 350 °C for B can most likely be related to the temperature above where significant recovery occurs. The temperature dependence of α is more evident during the cryo-cooling were filings that had not been heated or cooled before were cooled down in situ from room temperature to − 45 °C. It can be seen, that α obtained from the cryo-cooling is significantly larger at temperatures below 0 °C compared to + 45 °C for the studied alloys. α increases up to roughly to 18 × 10−3 and 16 × 10−3 at − 13 °C for alloy A and B, respectively, and up to 20 × 10−3 for alloy C at − 45 °C. The decrease in temperature causes a widening of the faulted volume, which is observable as an increase in α. As mentioned above, elevated temperatures may cause recovery and therefore reduce the overall faulted volume within the filings. In contrast, the filings used during cryo-cooling experiment were investigated in the as-deformed state. Since no recovery can occur at these low temperatures, nor was there any deformation generating new dislocations or SFs, ρ and the number of SFs can be assumed to be constant during the cryo-cooling experiment. Thus, the apparent increase in α results from the increasing volume of SFs only and is therefore directly related to a decrease in \({\gamma }_{\rm SFE}.\)

Following the argumentation that the size of an SFs and therefore α is inversely proportional to \({\gamma }_{\rm SFE}\) (see Eq. [6]), the alloy with the smallest value of \({\gamma }_{\rm SFE}\) should result in the highest magnitude of α and vice versa. However, no clear difference was observed between the alloys, which is quite reasonable considering the small difference in the alloy compositions of the studied materials (see Table I) and the measurement accuracy.

It is known, that recovery of dislocations and SFs starts at temperatures above about 200 °C, which causes a further decrease in the evaluated α and leads to some non-reversibility.[60,61] Thus, the temperature effect on the width of SFs is dominant at temperatures below 200 °C (see Section III–C). With Eq. [6], and restricting the obtained α to temperatures from − 45 °C to 200 °C, where ρ and thus \({\langle {\varepsilon }_{50}^{2}\rangle }_{111}\) can be assumed to be constant, it is therefore possible to relate the change in α directly to a change in \({\gamma }_{\rm SFE}.\) Considering the temperature dependence of \({a}_{0}\) and \({G}_{111}\)[62,63] and \({\gamma }_{\rm SFE}\) at room temperature calculated by ab initio (Figure 6) Eq. [6] results in a linear increase of \({\gamma }_{\rm SFE}\) of \(\left|\Updelta {\gamma }_{\rm SFE}/\Updelta T\right|=0.05 {\text{mJ}} {\text{m}}^{-2}/{\text{K}}\) which is similar for all studied alloys.

Regarding the experimental methodology applied in the present work it should be noted that Line profile analysis (LPA) can be used to evaluate a range of crystalline imperfections. This is based on the fact that diffraction peaks change their shape and position when they originate from an imperfect crystal. In the present work, the most prone crystalline imperfection giving rise to aberrations are crystallite size, size distribution, dislocations and planar faults. According to Ungár, these crystalline imperfections lead to peak shift, peak broadening, peak asymmetry as well as anisotropic peak broadening and shape.[26] The aberrations used in order to quantify α is the peak shift. As mentioned in chapter 2.3, planar faults lead to shifting and asymmetry of the peak position. A revision was done by Velterop et al. 25 in which the aim was to improve Warren’s approach and to remove the assumptions that fault probabilities need to be small and equal for all fault planes, as well as that the crystallites in the sample have to be randomly oriented. In the present study, those adjustments of the approach are not needed considering that the determined α is small and since powder is used where texture effects can be neglected. Due to the reasons given above it is considered appropriate to evaluate α by considering the peak shift only. It should though be mentioned that Velterop et al. argue that using more than one diffraction peak might lead to overestimation of α if the approach by Warren is used. On the other hand, it has been shown that intrinsic and extrinsic stacking faults have the opposite effect on the peak shift.[23,27] In this study, peak shift appears to be solely due to intrinsic stacking faults, but it cannot be neglected that some extrinsic stacking faults exist, which hence, would lead to an underestimation of α.

3.2 Ab initio Results and Effect of Magnetism

As discussed in Section II–D, an accurate description of the magnetic contribution to the free energy of austenitic steels is crucial in order to correctly describe both, the lattice parameter[52,64] and \({\gamma }_{\rm SFE}\)[52,64,65] as a function of temperature. One of the key parameters is the local magnetic moment.[66] Figure 5 shows the local magnetic moments of Fe, Cr and Ni atoms as a function of temperature obtained by utilizing the LSF-1 and LSF-2 models described in Section II–D. It can be seen, that in both models, an increase of temperature leads to a slight increase of Fe, Cr, and Ni magnetic moments. Furthermore, the LSF-2 model provides a lower magnetic moment of all considered atoms compared to the LSF-1 model. As previously reported, these results are close to the results obtained by the DLM model for Fe.[33] The LSF-1 model is appropriate for the LSF energies of Ni and Cr, having a parabolic form, while the LSF energy for Fe can be described satisfactorily by a fourth-order polynomial; the applied LSF-1 model also works reasonably for the LSF-induced magnetic moment of Fe.[33] However, the model slightly overestimates the local magnetic moment of Fe, but the LSF-1 model was still used for Fe in order to maintain a consistent description of the magnetic energy at low temperatures.

The volume dependence of \({\gamma }_{\rm SFE}\) contributes substantially to the temperature dependence of \({\gamma }_{\rm SFE}\)[52,64] and an approach fully based on first-principles would require a theoretical evaluation of the lattice constants which are subsequently used in the \({\gamma }_{\rm SFE}\) calculations. However, the ab initio calculation of the lattice parameters’ temperature dependence for austenitic steel is a highly non-trivial task for a wide temperature range.[33,67] Although the LSF method can reproduce the temperature dependence of the lattice parameter at elevated temperatures in agreement with experimental data for some austenitic steels,[33,67] in this work, experimentally determined lattice parameters have been used for the \({\gamma }_{\rm SFE}\) calculations. The reason for this approach is two-fold. On the one hand it allows us to compare two different LSF magnetic models describing the magnetic state of austenitic steel and its calculated \({\gamma }_{\rm SFE}\). On the other hand, since it is not possible to accurately predict the lattice parameter over a large temperature range, it is the only way to ensure that the \({\gamma }_{\rm SFE}\) dependence on temperature is accurately predicted. Figure 6 shows the calculated \({\gamma }_{\rm SFE}\) compared to the experimental measurements for the austenitic Fe–Cr–Ni alloys. Both LSF models predict an increase of \({\gamma }_{\rm SFE}\) with increasing temperature, do however, provide slightly different temperature dependencies. The LSF-1 model shows a linear temperature dependence that agrees with the measured slope over the entire considered temperature range. In contrary, the LSF-2 model predicts a trend with a clear curvature at low temperatures which is distinct from the experimentally obtained slope and thus cannot reproduce the temperature dependence of \({\gamma }_{\rm SFE}\). This is mainly due to their sensitivity to the magnetic moments of Cr and Ni as shown in Figure 5. It should be noted that the LSF-1 model is supposed to handle the magnetic contributions of Ni and Cr accurately, whereas the description of Fe is less accurate but here applied to maintain consistency throughout the calculations.[33]

The magnetic state of steels plays an important role in their thermodynamics[37] and the accurate description of the magnetic state of austenitic steel at finite temperatures is crucial for the correct description of \({\gamma }_{\rm SFE}\) as a function of temperature. It should be mentioned that the interplay between the LSF magnetic excitations and the thermal lattice expansion is the main factor determining the anti-Invar effect.[52] The vibrational contribution has not been considered in this study. Methods, which allow us to correctly describe vibrational contributions along with other relevant free energy contributions such as configurational, electronic, and magnetic contributions in austenitic steels, are still under development.[33] Nevertheless, we believe that the results obtained in this work give a correct picture of the temperature dependence of \({\gamma }_{\rm SFE}.\) Moreover, the dependence of \({\gamma }_{\rm SFE}\) on the chemical composition of the alloys is also in agreement with literature. At room temperature, the calculated \({\gamma }_{\rm SFE}\) for A, B, and C are 22, 25, and 20 mJ m−2, respectively. These results suggest that the influence of Ni on the \({\gamma }_{\rm SFE}\) is dominant, whereas the effect of Cr appears to be minor. This is in agreement with the conclusions from A. Das.[5]

3.3 Discussion on Temperature Dependence of Stacking Fault Energy

The experimental values of \(|\Updelta {\gamma }_{\rm SFE}/\Updelta T|\) for all studied alloys are plotted in Figure 6. It can be seen, that the values agree with the LSF-1 model for all alloys, where the best agreement was found for Alloy B. Furthermore, the evaluated temperature dependence of \({\gamma }_{\rm SFE}\) is in reasonable agreement with prior experimental investigations[13,14,15,16,68] Although TEM has limitation if being used to determine \({\gamma }_{\rm SF}\), it is a direct experimental technique to resolve and measure the width of a single SF. The values determined in this study, utilizing in situ HEXRD, agree well with values determined previously utilizing TEM.[13,14,15,16] Rémy and Pineau 13 determined the temperature dependence of \({\gamma }_{\rm SFE}\) to \(|\Updelta {\gamma }_{\rm SFE}/\Updelta T|=\) 0.06 mJ m−2/K in for Fe–Mn–Cr–C. Moreover, Latanision and Ruff 14 concluded a temperature dependence of \(|\Updelta {\gamma }_{\rm SFE}/\Updelta T|=\) 0.04 and \(|\Updelta {\gamma }_{\rm SFE}/\Updelta T|=\) 0.03 mJ m−2/K studied the in Fe–18.3 wt pct Cr–10.7 wt pct Ni and Fe–18.7 wt pct Cr–15.9 wt pct Ni, respectively, in a temperature range from 27 °C to 327 °C. Considering the very similar chemical composition and temperature range, the applied methodology appears to be applicable to determine \({\gamma }_{\rm SFE}\) in austenitic steels. However, it is here argued that HEXRD has significant benefits due to its bulk characterization character which circumvents the problem of stress/strain relieve in thin-foils, and HEXRD also provides average measurements of many SFs instead of only measuring one or a few SFs as in TEM analysis. The obvious drawback on the other hand is the indirect nature of the HEXRD measurement. Nonetheless, the HEXRD method applied here provides robust results with small uncertainties. Moreover, they are compared to the ab initio calculations, which provide very similar temperature dependency of \({\gamma }_{\rm SFE}\) for the alloys under investigation. This combination of HEXRD and ab initio calculations hold promise for further complete systematic mapping of the composition and temperature dependence of \({\gamma }_{\rm SFE}\) in austenitic stainless steels. This could be pivotal for the tailoring of deformation characteristics of austenitic alloys.

However, it needs to be mentioned, that this comparison is made in a temperature range in which no significant recovery of SFs occurs. The annihilation of dislocations at high temperatures could lead to errors in the experimentally evaluated trend of \(|\Updelta {\gamma }_{\rm SFE}/\Updelta T|.\) Yang and Spruiell [60] investigated several austenitic stainless steels and noticed that recovery of the commercial 304 and 316 stainless steels start at around 220 °C. Furthermore, the annealing behavior of SFs was shown by Warren and Warekois.[61] Cold-worked alpha brass filings were annealed for 1 hour at various temperatures and ex situ measured at room temperature. A decreasing peak separation of affected hkl’s was observed at temperatures above 200 °C. No influence of the annealing procedure was found for temperatures below 200 °C. Furthermore, considering the short holding time between each temperature step in this study (8 minutes per temperature step) it is reasonable to assume, that the annihilation of stacking faults was limited at temperature below 200 °C and that the results obtained are not affected by a decreasing density due to annihilation. This is also indicated by the obtained \(|\Updelta {\gamma }_{\rm SFE}/\Updelta T|\) at temperatures below room temperature where the annihilation of SF and dislocation is less likely compared to elevated temperatures. It was found, that \(\alpha \) increased significantly with decreasing temperatures. However, above 200 °C recovery could play an important role counteracting the expansion of the faulted area and reducing peak shift. It should also be mentioned that a true temperature dependence of \({\gamma }_{\rm SFE}\) is not the only possible explanation for the experimentally observed change in \(\alpha \). Among other things, it has been pointed out that changes in the local composition may as well change the width of the SF with temperature[4,12,13,14] The Suzuki effect can cause a deviation of the equilibrium concentration of solutes in the fault (hcp) from the equilibrium concentration of solutes in the matrix (fcc). As pointed out already by Abrassart[12] as well as Latanision and Ruff,[14] the Suzuki effect should lead to a decrease in \({\gamma }_{\rm SFE}\) with increasing temperature due to the increased diffusion of Ni and Cr from the fault in the matrix. However, the diffusivity in the considered temperature range is low and \({\gamma }_{\rm SFE}\) was observed to increase. Therefore, it appears, that in the present work, the Suzuki effect has no considerable impact on the results. Additionally, diffusion of interstitial atoms could potentially decrease the reversibility of the faulted volume, as it was argued by Latanision and Ruff[14] who observed in cyclic temperature experiments that the node size in the first cycle was irreversible and thereafter reversible in subsequent cycles. They further argue, that the Portevin–Le Chatelier effect, which was observed to be more prominent at temperatures up to 200 °C, might also influence the irreversibility. In this study, however, the concentration of interstitial elements is very low and the irreversibility is observed at higher temperatures only. Thus, the effect of segregation of interstitial atoms can be neglected. Thus, the irreversibility observed in this study is best explained by the annihilation of SFs at temperature above 200 °C.

4 Conclusions

The dependence of \({\gamma }_{\rm SFE}\) on temperature in the bulk of three austenitic stainless steels was evaluated both experimentally via in situ synchrotron X-ray diffraction and by ab initio calculations. The variation of the stacking fault probability was measured in a temperature range from − 45 °C to 450 °C, and directly correlated to the temperature dependence of \({\gamma }_{\rm SFE}.\) All three studied Fe–Cr–Ni alloy compositions show a similar temperature behavior. A linear increase of \({\gamma }_{\rm SFE}\) with increasing temperature of \(\left|\Updelta {\gamma }_{\rm SFE}/\Updelta T\right|=0.05 \,{\text{mJ}} {\text{m}}^{-2}/{\text{K}}\) was observed between − 45 °C and 250 °C, whereas above 250 °C an irreversibility effect was observed. The irreversibility effect of the stacking fault volume is due to recovery of dislocations above about 250 °C. The experimentally observed temperature dependence of \({\gamma }_{\rm SFE}\) is in excellent agreement with ab initio calculations using the longitudinal spin fluctuation model 1. The other ab initio model applied, the longitudinal spin fluctuation model 2, predict a non-linear trend of \({\gamma }_{\rm SFE}\) which disagree with the experimental measurements. The treatment of the magnetic moments of the individual elements is critical for accurate predictions of \({\gamma }_{\rm SFE}\) from the ab initio calculations.

References

G.B. Olson and M. Cohen: Metall. Trans. A., 1975, vol. 6, pp. 791–5.

S. Curtze, V.-T. Kuokkala, A. Oikari, J. Talonen, and H. Hänninen: Acta Mater., 2011, vol. 59, pp. 1068–76.

S. Curtze and V.-T. Kuokkala: Acta Mater., 2010, vol. 58, pp. 5219–5141.

P.C.J. Gallagher: Metall. Trans., 1970, vol. 1, pp. 2429–61.

A. Das: Metall. Mater. Trans. A., 2016, vol. 47A, pp. 748–68.

V. Shterner, A. Molotnikov, I. Timokhina, Y. Estrin, and H. Beladi: Mater. Sci. Eng. A., 2014, vol. 613, pp. 224–31.

S. Allain, J.-P. Chateau, O. Bouaziz, S. Migot, and N. Guelton: Mater. Sci. Eng. A., 2004, vol. 387, pp. 158–62.

S. Martin, S. Wolf, U. Martin, L. Krueger, and D. Rafaja: Metall. Mater. Trans. A., 2016, vol. 47A, pp. 49–85.

Y. Tian, O.I. Gorbatov, A. Borgenstam, A.V. Ruban, and P. Hedström: Metall. Mater. Trans. A., 2017, vol. 48A, pp. 1–7.

Y. Tian, S. Lin, J.Y. Ko, U. Lienert, A. Borgenstam, and P. Hedström: Mater. Sci. Eng. A., 2018, vol. 734, pp. 281–90.

T.C. Tisone: Acta Metall., 1973, vol. 21, pp. 229–36.

F. Abrassart: Metall. Trans., 1973, vol. 4, pp. 2205–16.

L. Rémy, A. Pineau, and B. Thomas: Mater. Sci. Eng., 1978, vol. 36, pp. 47–63.

R.M. Latanision and A.W. Ruff: Metall. Trans., 1971, vol. 2, pp. 505–9.

F. LeCroisey and B. Thomas: Phys. Status Solidi., 1970, vol. 2, p. K217.

L. Rémy: Acta Metall., 1977, vol. 25, pp. 73–179.

D.B. Williams, C.B. Carter, D.B. Williams, and C.B. Carter: Transmission Electron Microsc., 1996, https://doi.org/10.1007/978-1-4757-2519-3_6.

B. Neding: Stacking fault energies in austenitic stainless steels—an in-situ synchrotron x-ray diffraction study, Poster presented at TMS, March 2019, San Antonio, TX.

A.C. Dippel, et al.: J. Synchrotron Rad., 2015, vol. 22, pp. 675–87.

A. P. Hammersley: ESRF Internal Report, ESRF97HA02T, 1997.

A.P. Hammersley, S.O. Svensson, M. Hanfland, A.N. Fitch, and D. Hausermann: High Press. Res., 1996, vol. 14, pp. 235–48.

C.M. Fancher G. Esteves, K. Ramos, and J.L. Jones: Lipras, 2017, https://doi.org/10.13140/RG.2.2.29970.25282/3.

B.E. Warren: X-ray Diffraction, Dover, New York, 1990.

M.S. Paterson: J. Appl. Phys., 1952, vol. 23, p. 805.

L. Velterop, R. Delhez, Th.H. de Keijser, E.J. Mittemeijer, and D. Reefman: J. Appl. Crystallogr., 2000, vol. 33, pp. 296–306.

T. Ungár: Scripta Mater., 2004, vol. 51, pp. 777–81.

L. Balogh, G. Ribárik, and T. Ungár: J. Appl. Phys., 2006, vol. 100, p. 023512.

R.P. Reed and R.E. Schramm: Metall. Trans. A., 1975, vol. 6A, pp. 1345–51.

R.P. Reed and R.E. Schramm: J. Appl. Phys., 1974, vol. 45, pp. 4705–11.

R.P.I. Adler, H.M. Otte, and C.N.J. Wagner: Metall. Trans., 1970, vol. 1, pp. 2375–82.

R.E. Smallman and K.H. Westmacott: Philos. Mag., 1957, vol. 2, pp. 669–83.

A.K. Majumdar and P.V. Blanckenhagen: Phys. Rev. B., 1984, vol. 29(7), p. 4079.

A.V. Ruban and M. Dehghani: Phys. Rev. B., 2016, vol. 94(10), p. 104111.

A.V. Ruban, A.B. Belonoshko, and N.V. Skorodumova: Phys. Rev. B., 2013, vol. 87(1), p. 14405.

S. Khmelevskyi: J. Magn. Magn. Mater., 2018, vol. 461, pp. 14–8.

A.I. Lichtenstein, M.I. Katsnelson, and G. Kotliar: Phys. Rev. Lett., 2001, vol. 87, p. 067205.

O.I. Gorbatov, Y.N. Gornostyrev, P.A. Korzhavyi, and A.V. Ruban: Phys. Met. Metallogr., 2016, vol. 117, pp. 1293–327.

B.L. Gyorffy, A.J. Pindor, J.B. Staunton, G.M. Stocks, and H. Winter: J. Phys. F Met. Phys., 1985, vol. 15, pp. 1337–86.

I.A. Abrikosov, A.V. Ponomareva, P. Steneteg, S.A. Barannikova, and B. Alling: Curr. Opin. Solid State Mater. Sci., 2016, vol. 20(2), pp. 85–106.

A.V. Ruban, S. Khmelevskyi, P. Mohn, and B. Johansson: Phys. Rev. B., 2007, vol. 75(5), p. 054402.

J.B. Staunton and B.L. Gyorffy: Phys. Rev. Lett., 1992, vol. 69(2), p. 371.

S.V. Halilov, H. Eschrig, A.Y. Perlov, and P.M. Oppeneer: Phys. Rev. B., 1998, vol. 58(1), p. 293.

S. Khmelevskyi and P. Mohn: AIP Adv., 2018, vol. 8, p. 101422.

P.J.H. Denteneer and W. van Haeringen: J. Phys. C., 1987, vol. 20, p. L883.

B.D. Cooman, Y. Estrin, and S.K. Kim: Acta Mater., 2018, vol. 142, pp. 283–362.

Z. Pei: Mater. Sci. Eng. A., 2018, vol. 737, pp. 132–50.

L. Vitos, J.-O. Nilsson, and B. Johansson: Acta Mater., 2006, vol. 54, pp. 3821–6.

V.I. Razumovskiy, C. Hahn, M. Lukas, and L. Romaner: Materials., 2019, vol. 12, p. 1129.

L. Vitos: Phys. Rev. B., 2001, vol. 64, p. 14107.

L. Vitos, I.A. Abrikosov, and B. Johansson: Phys. Rev. Lett., 2001, vol. 87, p. 156401.

N.D. Mermin: Phys. Rev., 1965, vol. 137, p. A1441.

A. Reyes-Huamantinco, P. Puschnig, C. Ambrosch-Draxl, O.E. Peil, and A.V. Ruban: Phys. Rev. B., 2012, vol. 86(6), p. 060201.

J.P. Perdew, K. Burke, and M. Ernzerhof: Phys. Rev. Lett., 1996, vol. 77, pp. 3865–8.

H.J. Monkhorst and J.D. Pack: Phys. Rev. B., 1976, vol. 13, pp. 5188–92.

I.A. Abrikosov, S.I. Simak, B. Johansson, A.V. Ruban, and H.L. Skriver: Phys. Rev. B., 1997, vol. 56, p. 9319.

O.E. Peil, A.V. Ruban, and B. Johansson: Phys. Rev. B., 2012, vol. 85, p. 165140.

A.V. Ruban and H.L. Skriver: Phys. Rev. B., 2002, vol. 66, p. 024201.

A.V. Ruban, S.I. Simak, P.A. Korzhavyi, and H.L. Skriver: Phys. Rev. B., 2002, vol. 66, p. 024202.

H. Putz and K. Brandenburg: Diamond—Crystal and Molecular Structure Visualization, Crystal Impact, Bonn, Germany, http://www.crystalimpact.com/diamond.

W. Yang and J.E. Spruiell: J. Mater. Sci., 1982, vol. 17, pp. 667–90.

B.E. Warren and E.P. Warekois: J. Appl. Phys., 1953, vol. 24, pp. 951–2.

Inco Alloys: Engineering properties at elevated temperatures, The International Nickel Company, 1978.

H.M. Ledbetter, W.F. Weston, and E.R. Naimon: J. Appl. Phys., 1975, vol. 46, pp. 3855–60.

V.I. Razumovskiy, A. Reyes-Huamantinco, P. Puschnig, and A.V. Ruban: Phys. Rev. B., 2016, vol. 93, p. 054111.

J. Lu, L. Hultman, E. Holmström, K.H. Antonsson, M. Grehk, W. Li, L. Vitos, and A. Golpayegani: Acta Mater., 2016, vol. 111, pp. 39–46.

L. Vitos, P.A. Korzhavyi, and B. Johansson: Phys. Rev. Lett., 2006, vol. 96, p. 117210.

A.V. Ruban: Phys. Rev. B., 2017, vol. 95(17), p. 174432.

A. Saeed-Akbari, J. Imlau, U. Prahl, and W. Bleck: Metall. Mater. Trans. A., 2009, vol. 40A, pp. 3076–90.

Acknowledgments

This work was performed within the VINN Excellence Center Hero-m 2i, financed by VINNOVA, the Swedish Governmental Agency for Innovation Systems, Swedish industry and KTH Royal Institute of Technology. First-principles calculations were carried out with support provided by the Ministry of Education and Science of the Russian Federation (No. 074-02-2018-329 from May 16, 2018, Grant 14.Z50.31.0043). O.I.G. acknowledges support the Knut and Alice Wallenberg Foundation. The computations were performed on resources provided by the Swedish National Infrastructure for Computing (SNIC) at the National Supercomputer Center (NSC) in Linköping, at the High Performance Computing Center North (HPC2N) in Umeå.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Funding

Open access funding provided by Royal Institute of Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted May 31, 2021; accepted September 26, 2021.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Neding, B., Gorbatov, O.I., Tseng, JC. et al. In Situ Bulk Observations and Ab Initio Calculations Revealing the Temperature Dependence of Stacking Fault Energy in Fe–Cr–Ni Alloys. Metall Mater Trans A 52, 5357–5366 (2021). https://doi.org/10.1007/s11661-021-06473-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-021-06473-5