Abstract

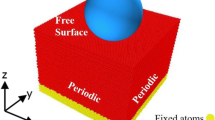

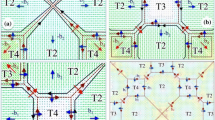

The present work aims to develop a geometrically necessary dislocations (GNDs) generation model to accommodate the mismatch of the coefficient of thermal expansion (CTE) and elastic modulus between the matrix and reinforcement. Interstitial prismatic loops have been punched in the spherical ceramic reinforced matrix. The developed model is verified using nanoindentation experimentation into the metal matrix nanocomposite (MMnC). The nanoreinforcements are in-situ developed into the Mg matrix. As per hypothesis, Taylor strengthening dominates the Orowan and Hall–Petch strengthening. The experimentally obtained yield strength is very close to the theoretically estimated one.

Similar content being viewed by others

References

T.W. Clyne and P.J. Withers: An Introduction to Metal Matrix Composites. Cambridge: Cambridge University Press, 1993.

N.M. Chelliah, H. Singh, and M.K. Surappa: Mater. Chem. Phys., 2017, vol. 194, pp. 65–76.

N. Tahreen, D.F. Zhang, F.S. Pan, X.Q. Jiang, D.Y. Li, and D.L. Chen: J. Mater. Sci. Technol., 2018, vol. 34, pp. 1110–18.

M.F. Ashby: Phil. Mag., 1969, vol. 21, pp. 399–424.

G.I. Taylor: Proc. R. Soc. London, Ser. A, 1934, vol. 145, pp. 362–404.

R.J. Arsenault and N. Shi: Mater. Sci. Eng., 1986, vol. 81, pp. 175–87.

W.S. Miller and F.J. Humphreys: Scripta Metall. Mater., 1991, vol. 25, pp. 33–38.

L.H. Dai, Z. Ling, and Y.L. Bai: Compos. Sci. Technol., 2001, vol. 61, pp. 1057–63.

A. Sanaty-Zadeh: Mater. Sci. Eng. A, 2012, vol. 531, pp. 112–18.

V.C. Nardone and K.M. Prewo: Scripta Metall., 1986, vol. 20, pp. 43–48.

M.S. Kujur, V. Manakari, G. Parande, K.S. Tun, A. Mallick, and M. Gupta: Ceram. Int., 2018, vol. 44, pp. 15035–15043.

C.S. Goh, M. Gupta, J. Wei, and L.C. Lee: J. Compos. Mater., 2007, vol. 41, pp. 2325–35.

J.F. Nye: Acta Metall., 1953, vol. 1, pp. 153–62.

W.D. Nix and H. Gao: J. Mech. Phys. Solids, 1998, vol. 46, pp. 411–25.

H. Singh, D. Kumar, and H. Singh: J. Compos. Mater., https://doi.org/10.1177/0021998320946432.

H. Singh, S. Kumar, and D. Kumar: Mater. Sci. Eng. A, 2020, vol. 789, pp. 1–9.

U.C. Archiopoli, N. Mingolo, and O.E. Martínez: Surf. Coat. Technol., 2011, vol. 205, pp. 3087–92.

C.H. Cáceres, J.R. Griffiths, A.R. Pakdel, and C.J. Davidson: Mater. Sci. Eng. A, 2005, vol. 402, pp. 258–68.

B.Q. Han and D.C. Dunand: Mater. Sci. Eng. A, 2000, vol. 277, pp. 297–304.

N.M. Chelliah, H. Singh, R. Raj, and M.K. Surappa: Mater. Sci. Eng. A, 2017, vol. 685, pp. 429–38.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 28, 2020, accepted September 3, 2020.

Rights and permissions

About this article

Cite this article

Singh, H., Kumar, D. Validation of Novel Geometrically Necessary Dislocations Calculation Model Using Nanoindentation of the Metal Matrix Nanocomposite. Metall Mater Trans A 51, 6700–6705 (2020). https://doi.org/10.1007/s11661-020-06016-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-06016-4