Abstract

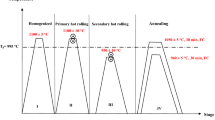

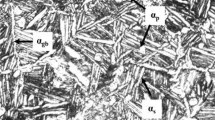

In this study, the microstructural characteristics and mechanical properties of Ti-1.0Fe alloy with equiaxed α + β microstructures were investigated in detail. Four different equiaxed α + β microstructures with β phase fraction ranging from 3 to 26 pct were obtained by hot deforming the martensite initial microstructure in α + β two-phase region with different deformation temperatures and cooling rates. The average nano-hardness of β grains was found to be much larger than that of α grains, which was attributed to the higher Fe concentration as well as nano-sized athermal ω precipitates inside the β grains. As a result, plastic strain partitioning occurred between the two phases during the tensile deformation, where the plastic strain within the soft α grains was much larger. With the increase of the β phase fraction, both yield and tensile strength of the samples increased, while at the same time, the total elongation gradually decreased. Most of the micro-cracks formed at the α/β interphase boundaries and propagated across the narrowest part of β phase. In the sample with the largest β phase fraction (26 pct), strain-induced β to α′ phase transformation occurred at the expense of initial athermal ω precipitates during the tensile deformation. This resulted into local nano-hardness variations between transformed and un-transformed β areas. Consequently, much more micro-cracks formed in this sample either at the boundaries between transformed and un-transformed β areas, or around the strain-induced α′ phase with a plate-like morphology. This explained the premature fracture shortly after necking in the sample with the largest β phase fraction.

Similar content being viewed by others

References

[1] D. Banerjee and J.C. Williams: Acta Mater, 2013, vol. 61, pp. 844-879.

G. Lutjering and J.C. Williams, Titanium, 2nd edition, Springer, Berlin, 2005.

[3] L.A. Maltakhova, A.N. Maltakhov, S.N. Monteiro, S.G. Fedotov, B.A. Goncharenko, Mater Sci Eng A, 2005, vol. 393, pp. 320-326.

[4] V. Lyasotskaya, S. Fedotov, S. Knyazeva, A. Dmitriev, Metal Sci Heat Treat, 1993, vol. 35, pp. 242-246.

[5] A.R. Kilmametov, Yu. Ivanisenko, A.A. Mazilkin, B.B. Straumal, A.S. Gornakova, O.B. Fabrichnaya, M.J. Kriegel, D. Rafaja and H. Hahn: Acta Mater, 2018, vol. 144, pp. 337-351.

[6] B.B. Straumal, A.R. Kilmametov, Yu. Ivanisenko, A.S. Gornakova, A.A. Mazilkin, M.J. Kriegel, O.B. Fabrichnaya, B. Baretzky and H. Hahn, Adv Eng Mater, 2015, vol. 17, pp. 1835-1841.

A. Kilmametov, Y. Ivanisenko, B. Straumal, A.A. Mazilkin, A.S. Gornakova, M.J. Kriegel, O.B. Fabrichnaya, D. Rafaja and H. Hahn, Scr. Mater., 2017, vol. 136, pp. 46-49

[8] Yu. Ivanisenko, A. Kilmametov, H. Rosner and R.Z. Valiev, Int J Mater Res, 2018, vol. 99, pp. 36-41.

[9] Y. Chong, G.Y. Deng, A. Shibata, N. Tsuji, Adv Eng Mater, 2019, vol. 21, pp. 1900607.

[10] G.Y. Deng, T. Bhattacharjee, Y. Chong, R.X. Zheng, Y. Bai, A. Shibata, N. Tsuji, J All Comp, 2020, vol. 822, pp. 153604.

[11] M.J. Kriegel, A.R. Kilmametov, M. Rudolph, B.B. Straumal, A.S. Gornakova, H. Stocker, Yu. Ivanisenko, O.B. Fabrichnaya, H. Hahn and D. Rafaja, Adv Eng Mater, 2018, vol. 20, pp. 170093.

[12] S.L Semiatin, V. Seetharaman and I. Weiss, JOM, 1997, vol. 49, pp. 33-40.

[13] S.L. Semiatin, V. Seetharaman and I. Weiss, Mater Sci Eng A, 1999, vol. 263, pp. 257-271.

[14] T. Furuhara, B. Poorganji, H. Abe and T. Maki, JOM, 2007, vol. 59, pp. 64-67.

[15] S.L. Semiatin and T.R. Bieler, Acta Mater, 2001, vol. 49, pp. 3565-3573.

[16] Y. Chong and N. Tsuji, Mater Sci Forum, 2016, vol. 879, pp. 344-349.

[17] S. Mironov, M. Murzinova, S. Zherebtsov, G.A. Salishchev and S.L. Semiatin, Acta Mater, 2009, vol. 57, pp. 2470-2481.

[18] Y. Chong, T. Bhattacharjee, M-H. Park, A. Shibata and N. Tsuji, Mater Sci Eng A, 2018, vol. 730, pp. 217-222.

[19] H.H. Liu, M. Niinomi, M. Nakai, and K. Cho, Acta Mater, 2016, vol. 106, pp. 162-170.

[20] H.H. Liu, M. Niinomi, M. Nakai, K. Cho and H. Fujii, Scripta Mater, 2017, vol. 130, pp. 27-31.

[21] S.K. Sikka, K. Vohra and R. Chidambaram, Prog Mater Sci, 1982, vol. 27, pp. 245-310.

[22] N. Tsuji, Y. Ito, Y. Saito and Y. Minamino, Scripta Mater, 2002, vol. 47, pp. 893-899.

[23] N. Tsuji, Y. Saito, H. Utsunomiya and S. Tanigawa, Scripta Mater, 1999, vol. 40, pp. 795-800.

[24] P.J. Jacques, Q. Furnemont, F. Lani, T. Pardoen and F. Delannay, Acta Mater, 2007, vol. 55, pp. 3681-3693.

[25] S. Zaefferer, J. Ohlert and W. Bleck, Acta Mater, 2004, vol. 52, pp. 2765-2778.

[26] F.D. Fischer, G. Reisner, E. Werner, K. Tanaka, G. Cailletaud and T. Antretter, Int J Plasticity, 2000, vol. 16, pp. 723-748.

Acknowledgments

The authors are grateful to the financial support from Cross-ministerial Strategic Innovation Promotion Program (SIP) supported by the Cabinet Office of Japanese government and the Elements Strategy Initiative for Structural Materials (ESISM) in Kyoto University supported by the Ministry of Education, Culture, Sports, Science and Technology (MEXT), Japan.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted August 30, 2019.

Rights and permissions

About this article

Cite this article

Chong, Y., Zheng, R., Deng, G. et al. Investigation on the Microstructure and Mechanical Properties of Ti-1.0Fe Alloy with Equiaxed α + β Microstructures. Metall Mater Trans A 51, 2851–2862 (2020). https://doi.org/10.1007/s11661-020-05760-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05760-x