Abstract

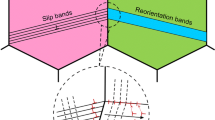

The through-thickness texture of an industrial hot-rolled Al-Mg-Si alloy plate is investigated both experimentally and numerically. The texture has been determined continuously from the plate center to the surface with large-scale electron backscatter diffraction scans. In accordance with literature results, a stable cube component and a strong brass component were found in the center, while the rotated cube component dominates the texture outside of the center region. A viscoplastic self-consistent polycrystal model including non-octahedral slip and grain shape evolution is shown to provide very good numerical predictions of the hot rolling texture. It captures the stability of the cube component and the gradients of the shear and brass component. However, it overestimates the intensity of the rotated cube component and wrongly predicts a stable goss component across the plate thickness. The calculation of deformation histories, which serve as boundary conditions for the polycrystal model, is presented and discussed.

Similar content being viewed by others

References

J. Hirsch and T. Al-Samman: Acta Mater., vol. 61, 2016, pp. 818-843.

I.L. Dillamore and W.T. Roberts: Metall. Rev., 1965, vol. 10., pp. 271-380.

N. Hansen and H. Mecking: in ICOTOM 4, G.J. Davies, I.L. Dillamore, R.C. Hudd and J.S. Kallend, eds., The Metals Society, London, 1975, pp. 34–46.

H.O. Asbeck and H. Mecking: Mater. Sci. Eng., 1978, vol. 34, pp. 111-19.

W. Truszkowski, J. Król and B. Major: Metall. Trans. A, 1980, vol. 11A, pp. 749-58.

O.V. Mishin, B. Bay and D. Juulensen: Metall. Mater. Trans. A, 2000, 31A, 1653-62.

I.L. Dillamore and H. Katoh: Met. Sci., 1975, vol. 8, pp. 73-83.

C.S. Lee, R.E. Smallman and B.J. Duggan: Mater. Sci. Technol., 1994, vol. 10, pp. 862-8.

O. Sukhopar and G. Gottstein: Int. J. Mater. Res., 2010, vol. 107, pp. 980-7.

A. Albou, S. Raavendra, P. Karajagikar, I. Samajdar, C. Maurice and J.H. Driver: Scripta Mater.. 2010, vol. 62, pp. 469-72.

B. Bacroix and J.J. Jonas: Texture Microstruct., 1988, 8, 267-311.

C. Maurice and J. Driver: Acta Metall. Mater., 1993, vol. 41, pp. 1653-64.

C. Maurice and J. Driver, Acta Mater., 1997, vol. 45, pp. 4627-38.

C. Maurice and J. Driver, Acta Mater., 1997, vol. 45, pp. pp. 4639-49.

D. Caillard, J.-L. Martin: Int. J. Mater. Res., 2010, vol. 100, pp. 1403-10.

P.A. Hollinshead and T. Sheppard: Metall. Mater. Trans. A, 1989, vol. 20A, pp. 1495-507.

H. Weiland and J. Hirsch: 1991, Texture Microstruct., 14, 647-52.

Q. Zhao, Z. Liu, S. Li, T. Huang, P. Xia and L. Lu: 2017, J. Alloy. Compd., 691, 786-99.

J.H. Driver, M.-C. Theyssier and C. Maurice: Mater. Sci. Technol., 1996, vol. 12, pp. 851-8.

S. Raveendra, H. Paranjape, S. Mishra, H. Weiland, R.D. Doherty and I. Samajdar: Metall. Mater. Trans A, 2009, vol. 40A, pp.2220-229.

I. Samajdar, P. Ratchev, B. Verlinden and E. Aernoudt: Acta Mater., 2001, vol. 49, pp. 1759-69.

W.C. Liu and J.G. Morris: Scripta Mater., 2005, vol. 52, pp. 1317-21.

Q. Contrepois, C. Maurice and J.H. Driver: Mat. Sci. Eng. A, 2010, vol. 527, pp. 7305-12.

M. Arzaghi, B. Beausir, L.S. Tóth: Acta Mater., vol. 57, 2009, pp. 2440-53.

S.V. Danilov, I.A. Mustaeva, M.A. Golovnin: Solid state phenom., vol. 265, 2017, pp. 999-1004.

J. Hirsch: Virtual fabrication of aluminum products: Microstructural modeling in industrial aluminum production, 2006, Wiley-VCH, Weinheim.

J. Hirsch: Mater. Sci. Forum, 2006, vols. 519-521, pp. 15-24.

J. Hirsch and K. Lcke: Acta metall., 1988, vol. 36, pp.2883-904.

O. Engler, M. Crumbach and S. Li: Acta mater., 2005, vol.53, pp. 2241-57.

P. Eisenlohr, D. D. Tjahjanto, T. Hochrainer, F. Roters and D. Raabe: Int. J. Mater. Res., 2009, vol. 100, pp. 500-9.

P. van Houtte, S. Li, M. Seefeldt and L. Delannay: Int. J. Plasticity, 2005, vol. 21, pp. 589-624.

D. Raabe: Acta Metall. Mater., 1995, vol. 43, pp. 1023-8.

M. Zezevic, R.A. Lebensohn, R.J. Cabe. M. : Int. J. Plasticity, vol. 109, 2018, pp. 193-211.

C.S. Lee and B.J. Duggan: Metall. Trans. A, 1991, vol. 22A, pp. 2637-43.

O. Engler, M.Y. Huh and C.N. Tomé: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 2299-315.

K. Decroos, J. Sidor and M. Seefeldt: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 948-61.

F. Pérocheau and J.H. Driver: Int. J. Plasticity, 2000, vol. 16, pp. 73-89.

R.A. Lebensohn and C.N. Tomé: Acta Metall. Mater., vol. 41, 1993, pp. 2611-24.

L.A.I. Kestens and H. Pirzaghi: Mater. Sci. Technol., 2016, vol. 32, pp. 1303-15.

J.A. Österreicher, F. Grabner, A. Schiffl, S. Schwarz and G.R. Bourret: Mater. Charact., 2018, vol. 138, pp. 145-53.

F. Bachmann, R. Hielscher and H. Schaeben: Solid State Phenom. 2010, vol.160, pp. 63-8.

P. Simon and G. Falkinger: \(11^{th}\) European LS-Dyna conference, 2017, Salzburg.

E. de Souzaneto, D. Peric and D.R.J. Owen, Computational Methods for Plasticity. Wiley, Chichester (2008).

K. Zhang, K. Marthinsen, B. Holmedal, T. Aukrust and A. Segatori: Mat. Sci. Eng. A, vol. 722, 2018, 20-9.

R.A. Lebensohn and C.N. Tomé: VPSC manual, Version 7c, 2009.

Y.-N. Kwon, Y.S. Lee, J.H. Lee: J. Mater. Process. Technol., 2007, vols. 187–188, pp. 533-6.

O. Engler, J. Hirsch: Mat. Sci. Eng. A, 2002, vol. 336, pp. 249-62.

F. Pérocheau and J.H. Driver: Int. J. Plasticity, 2002, vol. 18, pp. 185-202.

R. Quey, P.R. Dawson and J.H. Driver: J. Mech. Phys. Solids, vol. 60, 2012, pp.509-24.

C.G. Kang, H.G. Kang, H.C. Kim, M.Y. Huh and H.G. Suk: J. Mater. Process. Technol., 2007, vol. 187-188, pp.542-5.

C.-H. Choi, J.-W- Kwon, K.H. Oh and D.N. Lee: Acta mater., 1997, vol. 45, pp. 5119-28.

B. Hum, H. W. Colquhoun and J.G. Lenard: J. Mater. Process. Technol., vol. 60, 1996, pp. 331-8.

J.W. Yoon, F. Barlat, K. Chung, F. Pourboghrat and D.Y. Yang: Int. J. Plasticity, vol. 16, 2000, pp. 1075-104.

M. Zezevic and M. Knezevic: Comput. Method. Appl. M., vol. 341, 2018, pp. 888-916.

J. Segurado, R.A. Lebensohn, J. Llorca and C.N. Tomé: Int. J. Plasticity, vol. 28, 2012, pp. 124-40.

B. Plunkett, R.A. Lebensohn, O. Cazacu and F. Barlat: Acta Mater., vol. 54, 2006, pp. 4159-69.

M. Zezevic, R.J. McCabe and M. Knezevic: Int. J. Plasticity, 2015, vol. 70, pp.151-65.

D. Raabe, Z. Zhao, S.J. Park, F. Roters: Acta Mater., vol. 50, 2001, pp. 421-40.

L. Delannay, O.V. Mishin, D. Juul Jensen, P. van Houtte: Acta Mater., vol. 49, 2001, pp. 2441-451.

Acknowledgments

G.F. would like to thank Yi-Chin Yang, Franz Roters, and Dierk Raabe from the Max-Planck Institute für Eisenforschung in Düsseldorf, Germany for helpful discussions.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 23, 2019.

Rights and permissions

About this article

Cite this article

Falkinger, G., Simon, P. & Mitsche, S. Viscoplastic Self-consistent Modeling of the Through-Thickness Texture of a Hot-Rolled Al-Mg-Si Plate. Metall Mater Trans A 51, 3066–3075 (2020). https://doi.org/10.1007/s11661-020-05743-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05743-y