Abstract

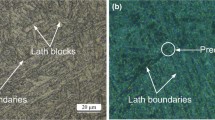

In this study, two different melting methods were used to investigate effects of Nb modification on microstructure in ultrahigh carbon steel (UHCS). Nb-free and Nb-modified UHCS samples were produced by melting and resolidifying an industrially produced base UHCS with and without addition of Nb powder. Microstructure was characterized using scanning electron microscopy, X-ray diffraction, and electron dispersive spectroscopy. Equilibrium computations of phase fractions and compositions were utilized to help describe microstructural changes caused by the Nb additions. Nb combined with C to form NbC structures before and during austenite solidification, reducing the effective amount of carbon available for the other phases. Cementite network spacing in the Nb-free samples was controlled by the cooling rate during solidification (faster cooling led to a more refined network). Network spacing in the Nb-modified UHCS could be enlarged by NbC structures that formed cooperatively with austenite.

Similar content being viewed by others

References

D.R. Lesuer, C.K. Syn, A. Goldberg, J. Wadsworth, and O.D. Sherby: JOM, 1993, vol. 45, pp. 40–46.

M.D. Hecht, B.A. Webler, and Y.N. Picard: Mater. Charact., 2016, vol. 117, pp. 134–43.

B. Walser and O.D. Sherby: Metall. Trans. A, 1979, vol. 10, pp. 1461–71.

M.A. Hamidzadeh, M. Meratian, and A. Saatchi: Mater. Sci. Eng. A, 2013, vol. 571, pp. 193–98.

M.A. Hamidzadeh, M. Meratian, and M. Mohammadi Zahrani: Mater. Sci. Eng. A, 2012, vol. 556, pp. 758–66.

G.D. de Almeida Soares, L.H. de Almeida, T.L. da Silveira, and I. Le May: Mater. Charact., 1992, vol. 29, pp. 387–96.

A. Noorian, S. Kheirandish, and H. Saghafian: Iran. J. Mater. Sci. Eng., 2010, vol. 7, pp. 22–29.

B.A. Migachev: Met. Sci. Heat Treat., 2001, vol. 43, pp. 103–6.

C. He-Xing, C. Zhe-Chuan, L. Jin-Cai, and L. Huai-Tao: Wear, 1993, vol. 166, pp. 197–201.

X. Zhi, J. Xing, H. Fu, and B. Xiao: Mater. Lett., 2008, vol. 62, pp. 857–60.

H. Mohrbacher: Materials Science and Technology Conference and Exhibition 2011, MS & T’11. Materials Science and Technology Conference and Exhibition 2011, MS & T’11. Columbus, OH, USA, 16–20 October 2011. pp. 434–45.

M.E. Maja, M.G. Maruma, L.A. Mampuru, and S.J. Moema: J. South. African Inst. Min. Metall., 2016, vol. 116, pp. 981–86.

M. Fiset, K. Peev, and M. Radulovic: J. Mater. Sci. Lett., 1993, vol. 12, pp. 615–17.

M.D. Hecht, Y.N. Picard, and B.A. Webler: Metall. Mater. Trans. A, 2017, vol. 48, pp. 2320–35.

M.D. Abràmoff, P.J. Magalhães, and S.J. Ram: Biophotonics Int., 2004, vol. 11, pp. 36–42.

R. Powell, T. Holland, and B. Worley: J. Metamorph. Geol., 1998, vol. 16, pp. 577–88.

K.G. Buchanan and M. V. Kral: Metall. Mater. Trans. A , 2012, vol. 43, pp. 1760–69.

F. Haddad, S.E. Amara, R. Kesri, and S. Hamar-Thibault: J. Phys. IV Fr., 2004, vol. 122, pp. 35–39.

E.E. Underwood: J. Microsc., 1969, vol. 89, pp. 161–80.

J. Wang, P. van der Wolk, and S. van der Zwaag: Mater. Trans. JIM, 2000, vol. 41, pp. 761–68.

Y.M. Won and B.G. Thomas: Metall. Mater. Trans. A, 2001, vol. 32, pp. 1755–67.

Acknowledgments

The authors appreciate Miller Centrifugal Casting for providing the mill roll parts for this study. This project was financed in part by a grant from the Commonwealth of Pennsylvania Department of Community and Economic Development (DCED), Developed in PA Program (D2PA). Funding support is also acknowledged from the National Science Foundation, CMMI Award No. 1436064. The authors acknowledge use of the Materials Characterization Facility at Carnegie Mellon University supported by Grant MCF-677785.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 29, 2017.

Rights and permissions

About this article

Cite this article

Hecht, M.D., Webler, B.A. & Picard, Y.N. Effects of Nb Modification and Cooling Rate on the Microstructure in an Ultrahigh Carbon Steel. Metall Mater Trans A 49, 2161–2172 (2018). https://doi.org/10.1007/s11661-018-4588-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4588-1