Abstract

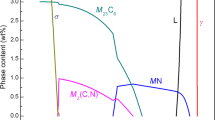

The Stellite 21 coating on the heat-resistant steel X12CrMoWVNbN10-1-1 (so-called COSTE) used in a steam turbine valve was found to be fatigue broken after service at around 873 K (600 °C) for about 8 years. In order to investigate the failure mechanism, a fresh Stellite 21 coating was also prepared on the same COSTE steel substrate by using the similar deposition parameters for comparison. It was found that the Stellite 21 coating was significantly diluted by the steel, resulting in a thin Fe-rich layer in the coating close to the fusion line. Such high Fe concentration together with the incessant Fe diffusion from the steel substrate to the coating during the service condition (about 873 K (600 °C) for long time) induced the eutectoid decomposition of the fcc α-Co(Fe,Cr,Mo) solid solution, forming an irregular eutectoid microstructure that was composed of the primitive cubic α′-FeCo(Cr,Mo) phase and the tetragonal σ-CrCo(Fe,Mo) phase. The brittle nature of such α′/σ eutectoid microstructure contributed to the fatigue fracture of the Stellite 21 coating, resulting in an intergranular rupture mode.

Similar content being viewed by others

References

Y.H. Yang, L.H. Zhu, Q.J. Wang, and C.C. Zhu: Mater. Sci. Eng. A, 2014, vol. 608, pp. 164–73.

Y. Zhang, Y.F. Sun, J.Y. Zhao, and S.K. Guan: J. Iron Steel Res. Int., 2012, vol. 19, pp. 62–66.

K.H. Lee, J.Y. Suh, S.M. Hong, J.Y. Huh, and W.S. Jung: Mater. Charact., 2015, vol. 106, pp. 266–72.

K. Sawada, T. Hara, M. Tabuchi, K. Kimura, and K. Kubushiro: Mater. Charact., 2015, vol. 101, pp. 106–13.

P. Yan, Z.D. Liu, H. Bao, Y.Q. Weng, and W. Liu: Mater. Des., 2014, vol. 54, pp. 874–79.

F. Abe, M. Tabuchi, and S. Tsukamoto: Energy Mater., 2012, vol. 4, pp. 166–74.

J.D. Majumdar, A. Kumar, and L. Li: Tribol. Int., 2009, vol. 42, pp. 750–53.

A. Gholipour, M. Shamanian, and F. Ashrafizadeh: J. Alloy Compd., 2011, vol. 509, pp. 4905–09.

J.R. Davis: Nickel, Cobalt, and Their Alloys, ASM International, Materials Park, 2000, pp. 362–70.

R.A. Jeshvaghani, M. Shamanian, and M. Jaberzadeh: Mater. Des., 2011, vol. 32, pp. 2028–33.

R. Liu, J.H. Yao, Q.L. Zhang, M. Yao, and R. Collier: Mater. Des., 2015, vol. 78, pp. 95–106.

A. Motallebzadeh, E. Atar, and H. Cimenoglu: Tribol. Int., 2015, vol. 91, pp. 40–47.

S. Brussk, A. Schrey, J. Barnikel, D. Weltersbach, and H. Starwald: Turbine Technical Conf. Expo., 2014, vol. 6, pp. 16–20.

J.N. Aoh, Y.R. Jeng, E. Chu, and L. Wu: Wear, 1999, vol. 225, pp. 1114–22.

R. Ahmed, A. Ashraf, M. Elameen, N.H. Faisal, A.M. El-Sherik, Y.O. Elakwah, and M.F.A. Goosen: Wear, 2014, vol. 312, pp. 70–82.

R. Singh, D. Kumar, S.K. Mishra, and S.K. Tiwari: Surf. Coating Technol., 2014, vol. 251, pp. 87–97.

A.P. Hammersley, S.O. Svensson, and A. Thompson: Detection Assoc. Equip., 1994, vol. 346, pp. 312–21.

J.W. Weeton and R.A. Signorelli: An Investigation of Lamellar Structures and Minor Phases in Eleven Cobalt-Base Alloys before and after Heat Treatment, National Advisory Committee for Aeronautics, Lewis Flight Propulsion Laboratory, OH, 1954.

F.Q. Xie and H.Z. Fu: Chin. Sci. Bull., 2000, vol. 45, pp. 131–34.

D.H.E. Persson: Ph.D. Thesis, Uppsala University, Uppsala, Sweden, 2003, pp. 112–13.

K. Easterling: Introduction to the Physical Metallurgy of Welding, 2nd ed., Butterworth-Heinemann Ltd, Oxford, United Kingdom, 1993, pp. 63–65.

K.N. Adhe, V. Kain, K. Madangopal, and H.S. Gadiyar: J. Mater. Eng. Performance, 1996, vol. 5, pp. 500–06.

R. Jendrzejewski, C. Navas, A. Conde, J. Damborenea, and G. Śliwiński: Mater. Des., 2008, vol. 29, pp. 187–192.

S. Shahab Naghavi, Vinay I. Hegde, and C. Wolverton: Acta Mater., 2017, vol. 132, pp. 467–78.

M.A. Kerkove, T.D. Wood, P.G. Sanders, S.L. Kampe, and D. Swenson: Metall. Mater. Trans. A, 2014, vol. 45A, pp. 3800–05.

K. Kawahara: J. Mater. Sci., 1993, vol. 18, pp. 1709–18.

A.M. Barakat, M.F. Abadir, K.T. Nam, A.M. Hamza, S.S. Al-Deyab, W. Baek, and H.Y. Kim: J. Mater. Chem., 2011, vol. 21, p. 10957.

T. Matkovic, L. Slokar, and P. Matkovic: J. Alloys Compd., 2006, vol. 407, p. 294.

A. Karaali, K. Mirouh, S. Hamamda, and P. Guiraldenq: Mater. Sci. Eng. A, 2005, vol. 390(1–2), p. 255.

S. Louidi, F.Z. Bentayeb, W. Tebib, J.J. Suñol, A.M. Mercier, and J.M. Grenèche: J. Non-Cryst. Solids, 2010, vol. 356, pp. 1052–56.

S.H. Zhang, T.Y. Cho, J.H. Yoon, W. Fang, K. Song, M.X. Li, Y.K. Joo, and C.G. Lee: Mater. Charact., 2008, vol. 59, pp. 1412–18.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 19, 2017.

Rights and permissions

About this article

Cite this article

Wang, D., Zhao, H., Wang, H. et al. Failure Mechanism of a Stellite Coating on Heat-Resistant Steel. Metall Mater Trans A 48, 4356–4364 (2017). https://doi.org/10.1007/s11661-017-4181-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-017-4181-z