Abstract

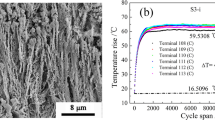

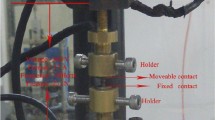

There are two major weaknesses for the AgSnO2 contacts used in the low voltage switch devices. One is poor workability, which causes the AgSnO2 materials to hardly deform into the required shape. Another is the increased contact resistance after arcing, which, in turn, causes an unfavorable temperature rise in the switches. In this article, the nanocomposited AgSnO2 materials were developed to overcome the weaknesses. The nanosized SnO2 powders with or without CuO additive were prepared by the chemical precipitation method. The SnO2 powders and Ag powders were high energy milled together to obtain AgSnO2 composite powders, which were then sintered, hot pressed and extruded. It was found that the SnO2 particles mainly distribute in the interior of Ag grains with Ag film on the grain boundary. The hardness of AgSnO2 composites and the wetting angle of Ag melt on SnO2 particles decreased with the addition of a small amount of CuO. By the combining effect of Ag film on grain boundary and the addition of CuO, the elongation and workability of the AgSnO2 materials improved. The experiments of rapid solidification revealed that more SnO2 particles with CuO addition were engulfed in the Ag matrix than those without CuO, which inhibited the redistribution of SnO2 particles on the contact surface during the arcing process. The industrial type test in the 45A contactor suggested that the nanocomposited AgSnO2 materials are suitable to be used as contacts in low voltage switches.

Similar content being viewed by others

References

P.C. Wingert and C.H. Leung: IEEE Trans. Comp. Hybrids. Manuf. Technol., 1987, vol. 10, pp. 56–62.

M. Huck, A. Kraus, R. Michal, and K.E. Saeger: IEEE, 1990, pp. 133–38.

D. Jeannot, J. Pinard, P. Ramoni, and E.M. Jost: IEEE, 1993, pp. 51–59.

D. Jeannot, J. Pinard, P. Ramoni, and E.M. Jost: IEEE Trans. A, 1994, vol. 17, pp. 17–23.

X.M. Liu, S.L. Wu, P.K. Chu, C.Y. Chung, J. Zheng, and S.L. Li: Mater. Chem. Phys., 2006, vol. 98, pp. 477–80.

W. Boehm, N. Behrens, and M. Clasing: Metall., 1981, vol. 35, pp. 539–43.

J. Feng, J.C. Chen, B. Xiao, and C.T. Zhou: Phys. B, 2009, vol. 404, pp. 2461–67.

M. Zhang, X.H. Wang, X.H. Yang, J.T. Zou, and S.H. Liang: Trans. Nonferrous Met. Soc. China, 2016, vol. 26, pp. 783–90.

V. Behrens, T. Honig, A. Kraus, R. Michal, K.E. Saeger, R. Schmidberger, and T. Staneff: IEEE Trans. CPMT Part A, 1994, vol. 17, pp. 24–31.

N. Lorrain, L. Chaffron, C. Carry, P. Delcroix, and G. Le Caër: Mater. Sci. Eng. A, 2004, vol. 367, pp. 1–8.

X.M. Liu, S.L. Wu, P.K. Chu, J. Zheng, and S.L. Li: Mater. Sci. Eng. A, 2006, vol. 426, pp. 274–77.

T. Mützel, P. Braumann, and R. Niederreuther: IEEE, 2009, pp. 200–05.

P. Verma, O.P. Pandey, and A. Verma: J. Mater. Sci. Technol., 2004, vol. 20, pp. 49–52.

Z. Ji, S.L. Li, F.Q. Dou, and T.H. Li: Rare Met., 2009, vol. 28, pp. 19–23.

V. Ćosović, A. Ćosović, N. Talijan, D. Živković, and D. Minić: J. Alloy Compd., 2013, vol. 567, pp. 33–39.

C.P. Wu, D.Q. Yi, J. Li, L.R. Xiao, B. Wang, and F. Zheng: J. Alloy Compd., 2008, vol. 457, pp. 565–70.

Q.B. Ye and Y.P. Wang: Mater. Sci. Eng. A, 2007, vol. 449, pp. 1045–48.

N. Kumari, A. Ghosh, and A. Bhattacharjee: Mater. Sci. Semicon. Proc., 2014, vol. 19, pp. 114–23.

M. Jung, J. Krausmann, M. Bender, J. Bachmann, and J. Rödel: J. Mater. Sci., 2015, vol. 50, pp. 4962–69.

G.C. Kuczynski: AIME Trans., 1949, vol. 185, pp. 169–78.

D.M. Stefanescu and B.K. Dhindaw: ASM Int., 1988, p. 142.

Acknowledgments

The authors acknowledge Q.B. Ye, J.Z. Wang, J.B. Wang, and H.Y. Liu for their assistance in the sample preparation and analysis. Thanks are also given for the financial support of the National Science Foundation of China (Grant Nos. 51171146 and 51607132) and the Program for Key Science and Technology Innovative Research Team of Shaanxi Province (Grant No. 2013KCT-05).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 5, 2016.

Rights and permissions

About this article

Cite this article

Wang, Y., Li, H. Improved Workability of the Nanocomposited AgSnO2 Contact Material and Its Microstructure Control During the Arcing Process. Metall Mater Trans A 48, 609–616 (2017). https://doi.org/10.1007/s11661-016-3859-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3859-y