Abstract

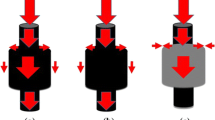

Spark plasma sintering has been a well-studied processing technique primarily for its very high cooling and heating rates. However, the underlying phenomenon driving the sintering behavior of powders under an electric field is still poorly understood. In this study, we look at the effect of changing current pathways through the powder bed by changing die materials, from conductive graphite to insulating boron nitride for sintering aluminum alloy 5083 powder. We found that the aluminum powder itself was insulating and that by changing the current paths, we had to find alternate processing methods to initiate sintering. Altering the current pathways led to faster temperature raises and faster melting (and potentially densification) of the aluminum powder. A flash sintering effect in metallic powders is observed in which the powder compact undergoes a rapid transition from electrically insulating to conducting at a temperature of 583 K (310 °C).

Similar content being viewed by others

References

1.) Z. Munir, U. Anselmi-Tamburini, and M. Ohyanagi: J. Mater.Sci., 2006, vol. 41, pp. 763-777.

2.) D. Hulbert, A. Anders, J. Andersson, E. Lavernia, and A. Mukherjee: Scr. Mater., 2009, vol. 60, pp. 835-838.

3.) E. Olevsky, and L. Froyen: Scr. Mater., 2006, vol. 55, pp. 1175-1178.

4.) L. Stanciu, V. Kodash, and J. Groza: Metall. Mater. Trans. A, 2001, vol. 32, pp. 2633-2638.

5.) M.Omori: Metall. Mater. Trans. A, 2000, vol. 31, pp. 183-188.

6.) R. Duan, G. Zhan, J. Kuntz, B. Kear, and A. Mukherjee: Mater. Sci. Eng., A, 2004, vol. 373, pp. 180-186.

7.) Z. Zhang, F. Wang, S. Lee, Y. Liu, J. Cheng, and Y. Liang: Mater. Sci. Eng., A, 2009, vol. 523, pp. 134-138.

8.) C. Shearwood, Y. Fu, L. Yu, and K. Khor: Scr. Mater., 2005, vol. 52, pp. 455-460.

9.) G. Kim, D. Shin, Y. Seo, and Y. Kim: Mater. Charact., 2008, vol. 59, pp. 1201-1205.

10.) R. Kumar, K. Prakash, P. Cheang, and K. Khor: Acta Mater., 2005, vol. 53, pp. 2327-2335.

W. Chen, U. Anselmi-Tamburini, J. Garay, J. Groza, J. and Z. Munir: Mater. Sci. Eng. A, 2005, vol. 394, pp. 132–38.

12.) U. Anselmi-Tamburini, S. Gennari, J. Garay, and Z. Munir: Mater. Sci. Eng. A, 2005, vol. 394, pp. 139-148.

13.) U. Anselmi-Tamburini, J. Garay, and Z. Munir: Mater. Sci. Eng. A, 2005, vol. 407, pp. 24-30.

14.) H. Conrad: Mater. Sci. Eng. A, 2000, vol. 287, pp. 227-237.

15.) J. Garay, U. Anselmi-Tamburini, and Z. Munir: Acta Mater., 2003, vol. 51, pp. 4487-4495.

16.) J. Friedman, J. Garay, U. Anselmi-Tamburini, and Z. Munir: Intermetallics, 2004, vol. 12, pp. 589-597.

17.) M. Cologna, B. Rashkova, and R. Raj: J. Am. Ceram. Soc., 2010, vol. 93, pp. 3556-3559.

18.) R. Raj, M. Cologna, and J. Francis: J. Am. Ceram. Soc., 2011, vol. 94, pp. 1941-1965.

19.) Y. Zhang and J. Luo: Scr. Mater., 2015, vol. 106, pp. 26-29.

23.) C. Carney, and T. Mah: J. Am. Ceram. Soc., 2008, vol. 91, pp. 3448-3450.

24.) J. Garay: Annu. Rev. Mater. Res., 2010, vol. 40, pp. 445-468.

25.) G. Xie, O. Ohashi, T. Yoshioka, M. Song, K. Mitsuishi, H. Yasuda, K. Furuya, and T. NodaI: Mater. Trans., 2001, vol. 42, pp. 1846-1849.

26.) B. McWilliams, J. Yu, and A. Zavaliangos: J. Mater. Sci., 2015, vol. 50, pp. 519-530.

27.) A. Zavaliangos, J. Zhang, M. Krammer, and J. Groza: Mater. Sci. Eng. A, 2004, vol. 379, pp. 218-228.

28.) L. Kowalski, B. Korevaar, and J. Duszczyk: J. Mater. Sci., 1992, vol. 27, pp. 2770-2780.

29.) L. Chen, W. Song, J. Lv, X. Chen, and C. Xie: Mater. Chem. Phys., 2010, vol. 120, pp. 670-675.

30.) Y. Li, W. Song, C. Xie, D. Zeng, A. Wang, and M. Hu: Mater. Chem. Phys., 2006, vol. 97, pp. 127-131.

31.) A. Lawley: J. Mater., 1990, vol. 42, pp. 12-14.

32.) Z. Trzaska, and J-P Monchoux: J. Alloys Compd., 2015, vol. 635, pp. 142-149.

33.) N. Toyofuku, T. Kuramoto, T. Imai, M. Ohyanagi, and Z. Munir: J. Mater. Sci., 2012, vol. 47, pp. 2201-2205

J. Frei, U. Anselim-Tamburini, and Z. Munir: J. Appl. Phys., 2007, vol. 101, pp. 114914-1, 114914-8.

20.) B. Nui, F. Zhang, J. Zhang, W. Ji, W. Wang, and Z. Fu: Scr. Mater., 2016, vol. 116, pp. 127-130.

21.) S. Grasso, T. Saunders, H. Porwal, O. Cedillos-Barraza, D. Jayaseelan, W. Lee, and M. Reece: J. Am. Ceram. Soc., 2014, vol. 97, pp. 2405-2408.

22.) S. Grasso, E. Kim, T. Saunders, M. Yu, S. Choi, A. Tudball, and M. Reece: Cryst. Growth Des., 2016, vol. 16, pp. 2317-2321.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 9, 2016.

Rights and permissions

About this article

Cite this article

Kellogg, F., McWilliams, B. & Cho, K. Effect of Current Pathways During Spark Plasma Sintering of an Aluminum Alloy Powder. Metall Mater Trans A 47, 6353–6367 (2016). https://doi.org/10.1007/s11661-016-3803-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3803-1