Abstract

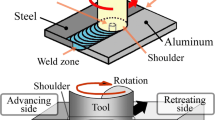

Multimaterial fabrication such as joining of steel and aluminum is currently prominent in a variety of industries. Friction stir welding is a novel solid-state welding process that causes good joint strength between steel and aluminum. However, the phenomenon contributing significant strength at the interface is not yet clear. In the present study, the interface of the friction stir lap-welded aluminum and coated steel sheet having joint strength maximum (71.4 pct of steel base metal) and minimum, respectively, under two parameter combinations, i.e., 1000 rpm 50 mm min−1 and 500 rpm 100 mm min−1, was exclusively characterized by X-ray diffraction, transmission electron microscopy (TEM), concentration profile, and elemental mapping by electron-probe microanalysis. A TEM-assisted EDS study identifies the morphologies of large size Al13Fe4 and small size Fe3Al-type intermetallic compounds at the interface. The diffusion-induced intermetallic growth (thickness) measured from a backscattered image and concentration profile agreed well with the numerically calculated one. The growth of these two phases at 1000 rpm 50 mm min−1 is attributed to the slower cooling rate (~3.5 K/s) with higher diffusion time (44 seconds) along the interface in comparison to the same for 500 rpm 100 mm min−1 with faster cooling rate (~10 K/s) and less diffusion time (13.6 seconds). The formation of thermodynamically stable and hard intermetallic phase Al13Fe4 at 1000 rpm and travel speed 50 mm min−1 in amounts higher than 500 rpm and a travel speed of 100 mm min−1 results in better joint strength, i.e., 71.4 pct, of the steel base metal.

Similar content being viewed by others

Notes

INSTRON is a trademark of Illinois Tool Works Inc. (ITW), Glenview, IL.

NANO INDENTER XP is a trademark of MTS Systems, Eden Prairie, MN.

JEOL-2000EX is a trademark of Japan Electron Optics Ltd., Tokyo.

GATAN PIPS is a trademark of Gatan, Inc., Warrendale, PA.

References

T. DebRoy and H.K.D.H. Bhadeshia: Sci. Technol. Weld. Join., 2010, vol.15, pp. 266–70.

T.A. Barnes and I.R. Pashby: J. Mater. Process. Technol., 2000, vol. 99, pp. 62–71.

S.H.C. Park, Y.S. Sato, and H. Kokawa: Proc. 7th Int. Symp., JWS, Kobe, Japan, 2001, pp. 639–44.

V.R. Ryabov: Foreign Technology Division, Wright-Patterson Air Force Base, OH, 1973, p. 16.

A. Elrefaey, M. Gouda, M. Takahashi, and K. Ikeuchi: J. Mater. Eng. Perform., 2005, vol. 14, pp. 10–17.

Maruzen, ed.: Welding Handbook, Japan Welding Society, Tokyo, 1990, p. 496.

M. Aritoshi and K. Okita: Q. J. Jpn Weld. Soc., 2002, vol. 71, pp. 432–36.

K. Ikeuchi, N. Yamamoto, M. Takahashi, and M. Aritoshi: Trans. JWRI, 2005, vol. 34, pp. 1–9.

W. Lee, M. Schmuecker, U.A. Mercardo, G. Biallas, and S. Jung: Scripta Mater., 2006, vol. 55, pp. 355–58.

K. Tanaka, M. Kumagai, and H.J. Yoshida: Jpn. Inst. Light Met., 2006, vol. 56, pp. 317–22.

K. Kimapong and T. Watanabe: Mater. Trans., JIM, 2005, vol. 46, pp. 835–41.

T. Watanabe, H. Takayama, and A. Yanagisawa: J. Mater. Proc. Technol., 2006, vol. 178, pp. 342–49.

Y.C. Chen and K. Nakata: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 1985–92.

H. Uzun, C.D. Donne, A. Argagnotto, T. Ghidini, and C. Gambaro: Mater. Des., 2005, vol. 26, pp. 41–46.

S. Bozzi, A.L.H. Etter, T. Baudin, B. Criqui, and J.G. Kerbiguet: Mater. Sci. Eng. A, 2010, vol. 527, pp. 4504–09.

H. Das, S. Basak, G. Das, and T.K. Pal: Int. J. Adv. Manufact. Technol., 2013, vol. 64, pp. 1653–61.

M. Movahedi, A.H. Kokabi, S.M. Seyed Reihani, and H. Najafi: Sci. Technol. Weld. Join., 2012, vol. 17, pp. 162–68.

S. Zimmer, L. Langlois, J. Laye, and R. Bigot: Int. J. Adv. Manufact. Technol., 2010, vol. 47, pp. 201–15.

R. Pretorius, A.M. Vredenberg, and F.W. Saris: J. Appl. Phys., 1991, vol. 70, pp. 3636–46.

R. Pretorius, R. de Reus, A.M. Vredenberg, and F.W. Saris: Mater. Lett., 1990, vol. 9, pp. 494–99.

H. Das, S.S. Jana, T.K. Pal, and A. De: Sci. Technol. Weld. Join., 2014, vol. 19, pp. 69–75.

N. Lee and J. Cahoon: J. Phase Equilib. Diff., 2011, vol. 32, p. 226.

J. Hirvonen and J. Raisanen: J. Appl. Phys., 1982, vol. 53, p. 3314.

J.W. Edington: Practical Electron Microscopy in Material Science, Van Nostrand Reinhold, New York, 1976.

M. Potesser, T. Schoeberl, H. Antrekowitsch, and J. Bruckner: EPD Congress, TMS, Warrendale, PA, 2006, pp. 167–176.

Acknowledgments

The financial support of the CSIR (New Delhi, India) for this work is gratefully acknowledged. The authors are very much thankful to Dr. G. Das, Principal Scientist, Mechanical Division, National Metallurgical Laboratory, Jamshedpur, and Drs. A. Dasgupta, A. Kumar, and T. Jayakumar, Metallurgy and Materials Group, Indira Gandhi Centre for Atomic Research (IGCAR, Kalpakkam, India), for extending their facility for EPMA and TEM.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 24, 2013.

Rights and permissions

About this article

Cite this article

Das, H., Ghosh, R.N. & Pal, T.K. Study on the Formation and Characterization of the Intermetallics in Friction Stir Welding of Aluminum Alloy to Coated Steel Sheet Lap Joint. Metall Mater Trans A 45, 5098–5106 (2014). https://doi.org/10.1007/s11661-014-2424-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2424-9