Abstract

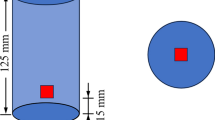

The rapid solidification of a peritectic alloy is studied. Various 2D and 3D characterization techniques were effectively utilized to investigate the effect of cooling rate on both the phase fractions and the shrinkage porosity. Particles of Al-36 wt pct Ni were produced using a drop tube impulse system. Neutron diffraction and Rietveld analysis were used to quantify the phases formed during solidification. The microstructure of the produced particles was analyzed using SEM and X-ray microtomography. It was found that increasing cooling rate resulted in decreasing the Al3Ni2 to Al3Ni ratio. Also, quantitative analysis of the microtomography images revealed that the volume percent of porosity increased with increasing particle size. The distribution of porosity was found to be significantly different in small and large particles. It was concluded that the extensive growth of Al3Ni2 at lower cooling rates followed by the peritectic reaction made the feeding of the shrinkages more difficult, and as a result, the volume percent of porosity increased. Other findings showed that high cooling rate during solidification would result in the formation of a quasicrystalline phase, known as D-phase, and suppression of the primary Al3Ni2. Also, investigation of the 3D structure of the solidified particles revealed that large particles of Al-36 wt pct Ni contain multiple nucleation sites, while smaller particles contain only one single nucleation site.

Similar content being viewed by others

References

Kerr H W and Kurz W 1996 Int. Mater. Rev. 41(4) 129-164.

Umeda T, Okane T and Kurz W 1996 Acta Mater. 44(10) 4209-4216.

Povarova K B, Lomberg B S, Filin S A, Kazanskaya N K, Shkol’nikov D Y and Bespalova M D 1994 Izv. Ross. Akad. Nauk, Ser. Met. 3 77-84.

Devred F, Reinhart G, Iles G N, Van D K, Adkins N J, Bakker J W, Nieuwenhuys B E 2011 Catal. Today 163(1) 13-19.

Ilbagi A, Delshad Khatibi P, Swainson I P, Reinhart G and Henein H 2011 Can. Metall. Q. 50(3) 295-302.

Bao C M, Dahlborg U, Adkins N and Calvo-Dahlborg M 2009 J. of Alloy. and Compd. 481 199–206.

A. Ilbagi, D. Tourret, H. Henein, and C.-A. Gandin: IOP Conf. Ser. Mater. Sci. Eng., 2012, vol. 33, p. 012060.

Prasad A, Henein H, Maire E and Gandin Ch-A 2004 Can. Metall. Q. 43(2) 273.

Prasad A, Henein H, Maire E and Gandin Ch-A 2006 Metall. Mater. Trans. A 37 249.

Henein H, Buchoud V, Schmidt R–R, Watt C, Malakhov D, Gandin Ch-A, Lesoult G, Uhlenwinkel V 2010 Can. Metall. Q. 49(3) 275.

A. Ilbagi, P. Delshad Khatibi, and H. Henein: Proc. PowderMet2011, San Francisco, CA, 2011.

Ilbagi A, Henein H and Phillion A B 2011 J Mater Sci 46:6235–6242.

Henein H 2002 Mater. Sci. Eng. A 326 92.

R.B. Von Dreele: Neutron Diffraction in Materials Science and Technology: A Comprehensive Treatment, vol. 2B, Wiley-VCH, New York, NY, 1994.

J.A. Patchett and G.J. Abbaschian: in Proc. Fourth Conf. Rapid Solidif. Process. Princ. Technol., R. Mehrabian and P.A. Parrish, University of California, Santa Barbara, CA, 1986.

W. Kurz and D.J. Fisher: Fundamentals of solidification, Transaction Technical Publication, Aedermannsdorf, 1989, p. 88.

D. Tourret and C.-A. Gandin: Acta Mater., 2009, vol. 57(7), pp. 2066–2079.

Pohla C and Ryder P L 1997 Acta Mater. 45 2155.

Shuleshova O, Holland-Moritz D, Loser W, Reinhart G, Iles G N and Buchner B 2009 Europhys. Lett. 86(3) 19.

Grushko B and Holland-Moritz D 1997 Mater. Sci. Eng. A. 226-228 999.

Pohla C and Ryder P L 1991 Mater. Sci. Eng. A, 134 947.

Acknowledgments

We would like to thank the National Research Council of Canada-Canadian Neutron Beam Centre, (NRC-CNBC), Chalk River, ON, Canada, and Ronald Donabergerfor for their support in conducting the neutron diffraction experiments. The authors also acknowledge access to beamtime from the Swiss Light Source, Paul Scherrer Institute, Villigen, Switzerland (Proposal No. 20100178). We are grateful to the Tomcat beamline group whose outstanding efforts have made these experiments possible. We would like to thank Dr. Julie Fife for her support in setting up the beamline and data collection. The assistance and support of Dr J. Johansson, D. Thornton, and M. Kazakevich in carrying out the 3D image analysis from microtomography are also acknowledged. We are grateful for the support of the Canadian Space Agency (CSA) and the Natural Sciences and Engineering Research Council of Canada (NSERC) for this project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 22, 2013.

Rights and permissions

About this article

Cite this article

Ilbagi, A., Henein, H. 3D Quantitative Characterization of Rapidly Solidified Al-36 Wt Pct Ni. Metall Mater Trans A 45, 2152–2160 (2014). https://doi.org/10.1007/s11661-013-2116-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-2116-x