Abstract

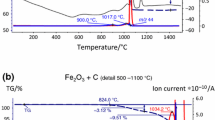

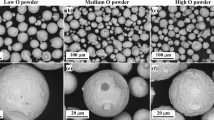

The main obstacle for utilization of Cr and Mn as alloying elements in powder metallurgy is their high oxygen affinity leading to oxidation risk during powder manufacturing, handling, and especially during further consolidation. Despite the high purity of the commercially available Cr- and Mn-prealloyed iron powder grades, the risk of stable oxide formation during the sintering process remains. Thermodynamic and kinetic simulation of the oxide formation/transformation on the former powder surface during heating and sintering stages using thermodynamic modeling tools (Thermo-Calc and HSC Chemistry) was performed. Simulation is based on the results from the analysis of amount, morphology, and composition of the oxide phases inside the inter-particle necks in the specimens from interrupted sintering trials utilizing advanced analysis tools (HRSEM + EDX and XPS). The effect of the processing parameters, such as sintering atmosphere composition, temperature profile as well as graphite addition on the possible scenarios of oxide reduction/formation/transformation for Fe-Cr-Mn-C powder systems, was evaluated. Results indicate that oxide transformation occurs in accordance with the thermodynamic stability of oxides as follows: Fe2O3 → FeO → Fe2MnO4 → Cr2FeO4 → Cr2O3 → MnCr2O4 → MnO/MnSiO x → SiO2. Spinel MnCr2O4 was identified as the most stable oxide phase at applied sintering conditions up to 1393 K (1120 °C). Controlled conditions during the heating stage minimize the formation of stable oxide products and produce oxide-free sintered parts.

Similar content being viewed by others

References

E. Hryha, E. Dudrova and S. Bengtsson, Powder Metall., 2008, vol. 51, pp. 340-42.

Höganäs AB, Iron and Steel Powders for Sintered Components. 1st ed., Höganäs AB, Höganäs, Sweden, 2002.

D. Chasoglou, E. Hryha, M. Norell, L. Nyborg (2013) Appl. Surf. Sci., 268, pp. 496–506.

E. Hryha, C. Gierl, L. Nyborg, H. Danninger, E. Dudrova (2010) Appl. Surf. Sci., 256, pp. 3946-61.

H. Karlsson, L. Nyborg and S. Berg, Powder Metall., 2005, vol. 48, pp. 51-58.

E. Hryha and L. Nyborg: Proceedings of World PM2010, vol. 2, EPMA, Florence, 2010, pp. 268–75.

O. Bergman, L. Nyborg, Powder Metall. Prog., 2010, vol. 10, pp.1-19.

E. Hryha, L. Nyborg, Powder Metall. Prog., 2011, vol. 11, pp. 42-50.

D. Chasoglou, E. Hryha and L. Nyborg: Mater. Chem. Phys., 2013, vol. 138, pp. 405–15.

E. Hryha and L. Nyborg: Proceedings of World PM2012, JPMA, Yokohama, 2013, 16A-T9-12 (CD-ROM).

D. Chasoglou, E. Hryha, and L. Nyborg: Powder Metall. Prog., 2011, vol. 11, pp. 32–41.

S. Kremel, H. Danninger and Y. Yu, Powder Metall. Prog., 2002, vol. 2, pp. 211-21.

O. Bergman, Powder Metall., 2007, vol. 50, pp. 243-49.

H. Danninger, C. Xu, and B. Lindqvist: Prog. Powder Metall., 2007, pp. 577–80.

H. Danninger and C. Gierl: Mater. Chem. Phys., 2001, vol. 67, pp. 49–55.

H. Danninger, C. Gierl, S. Kremel, G. Leitner, K. Jaenicke-Roessler, Y. Yu, Powder Metall. Prog., 2002, vol. 2, pp. 125-39.

P. Ortiz and F. Castro, Powder Metall., 2004, 47, pp. 291-98.

S. Karamchedu, E. Hryha and L. Nyborg, Powder Metall. Prog., 2011, vol. 11, pp. 90-96.

E. Hryha, E. Dudrova, and L. Nyborg: J. Mater. Process. Technol., 2012, vol. 212, pp. 977–87.

E. Hryha, L. Nyborg, A. Malas, S. Wiberg, S. Berg, Powder Metall., 2013, vol. 56, pp. 5-10.

D.L. Douglass, F. Gesmundo, and C. Asmundis, Oxid. Met., 1986, vol. 25, pp. 235–68.

I.H. Jung, Solid State Ionics, 2006, vol. 177, pp. 765-77.

L. Kjellqvist and M. Selleby, J. Alloys Compd., 2010, vol. 507, pp. 84-92.

O. Bergman: PhD Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2011.

Acknowledgments

The authors would like to thank VINNOVA (Swedish Agency for Innovation Systems) and Höganäs AB for financial support. Further thanks is also extended to Höganäs AB for scientific cooperation and permission to publish this research. Dr Ola Bergman, Höganäs AB, is greatly acknowledged for the fruitful discussions during manuscript preparation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted June 17, 2013.

Rights and permissions

About this article

Cite this article

Hryha, E., Nyborg, L. Oxide Transformation in Cr-Mn-Prealloyed Sintered Steels: Thermodynamic and Kinetic Aspects. Metall Mater Trans A 45, 1736–1747 (2014). https://doi.org/10.1007/s11661-013-1969-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1969-3