Abstract

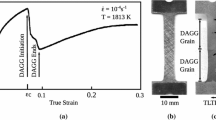

A new abnormal grain growth phenomenon that occurs only during continuous plastic straining, termed dynamic abnormal grain growth (DAGG), was observed in molybdenum (Mo) at elevated temperature. DAGG was produced in two commercial-purity molybdenum sheets and in a commercial-purity molybdenum wire. Single crystals, centimeters in length, were created in these materials through the DAGG process. DAGG was observed only at temperatures of 1713 K (1440 °C) and above and occurred across the range of strain rates investigated, ~10−5 to 10−4 s−1. DAGG initiates only after a critical plastic strain, which decreases with increasing temperature but is insensitive to strain rate. Following initiation of an abnormal grain, the rate of boundary migration during DAGG is on the order of 10 mm/min. This rapid growth provides a convenient means of producing large single crystals in the solid state. When significant normal grain growth occurs prior to DAGG, island grains result. DAGG was observed in sheet materials with two very different primary recrystallization textures. DAGG grains in Mo favor boundary growth along the tensile axis in a 〈110〉 direction, preferentially producing single crystals with orientations from an approximately 〈110〉 fiber family of orientations. A mechanism of boundary unpinning is proposed to explain the dependence of boundary migration on plastic straining during DAGG.

Similar content being viewed by others

References

J.G. Byrne: Recovery, Recrystallization, and Grain Growth, The MacMillian Company, New York, 1965, p. 106.

F. J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, Elsevier, New York, 2004, pp. 368–370.

J. Dennis, P.S. Bate, and F.J. Humphreys: Mater. Sci. Forum, 2007, vol. 558–559, pp. 717–722.

C. L. Briant, F. Zaverl, and W. T. Carter: Acta Metallurgica et Materialia, 1994, vol. 42, pp. 2811–2821.

V. Randle: Materials Science Forum, 1993, vol. 113–115, pp. 189–194.

J.B. Koo, D.Y. Yoon, and M.F. Henry: Metall. Mater. Trans. A, 2000, vol. 31A, pp. 1489–1491.

K. Takebe and Y. Hiraoka: Mo Alloy Single Crystal and Its Production, Japan Patent No. JP6248384, September 6, 1990.

T. Fujii, Y. Hiraoka and R. Watanabe: United States Patent No. 4,491,560, January 1 1985.

Y. Hiraoka, T. Fujii, T. Kainuma, M. Okada, and R. Watanabee: in Physical Metallurgy and Technology of Molybdenum and Its Alloys, K.H. Miska, M. Semchyshen, E.P. Whelan, and D.J. Kruzich, eds., AMAX Inc., Ann Arbor, MI, 1985, pp. 81–86.

J. R. Ciulik and E. M. Taleff: Sripta Materialia, 2009, vol. 61, pp. 895–898.

J.R. Ciulik: Ph.D. Thesis, The University of Texas at Austin, August 2005.

C. Musiol: Metals Technology, 1976, vol. 3, pp. 173–183.

R. C. Gifkins: Nature, 1952, vol. 169, pp. 238–239.

R.C. Gifkins: J. Inst. Met., 1953–54, vol. 82, pp. 39–47.

R.C. Gifkins: J. Inst. Met., 1957–58, vol. 86, pp. 15–16.

R.C. Gifkins: J. Inst. Met., 1958–59, vol. 87, pp. 255–61.

R. C. Gifkins: Transactions of the Metallurgical Society of AIME, 1959, vol. 215, pp. 1015–1022.

J. R. Ciulik and E. M. Taleff: Materials Science and Engineering A, 2007, vol. 463, pp. 197–202.

ASTM International: Standard Specification for Molybdenum and Molybdenum Alloy Plate, Sheet, Strip and Foil, Standard Designation B 306–03, ASTM International, West Conshohocken, PA, 2003.

ASTM International: Standard Test Method for Determination of Carbon in Refractory and Reactive Metals and Their Alloys, Standard Designation E 1941–04, ASTM International, West Conshohocken, PA, 2004.

ASTM International: Standard Test Methods for Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys by Various Combustion and Fusion Techniques, Standard Designation E 1019–08, ASTM International, West Conshohocken, PA, 2008.

D.L. Donohue and J.A. Carter: in Metals Handbook, 19th ed., vol. 10, J.R. Davis, ed., American Society for Metals, Metals Park, OH, 1986, pp. 141–50.

R. L. Barto and L. J. Ebert: Metallurgical Transactions, 1971, vol. 2A, pp. 1643–1649.

ASTM International: Standard Test Methods for Determining Average Grain Size, Standard Designation E 112–96, ASTM International, West Conshohocken, PA, 1996.

F. J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, Elsevier, New York, 2004, p. 334.

C.S. Barrett and T.B. Massalski: Structure of Metals: Crystallographic Methods, Principles and Data, 3rd revised ed., Pergamon Press, Oxford, UK, 1980.

A.D. Rollett and S.I Wright: in Texture and Anisotropy: Preferred Orientations in Polycrystals and their Effect on Material Properties, U.F. Kocks, C.N. Tomé, and H.-R. Wenk, eds., Cambridge University Press, Cambridge, UK, 1998, pp. 178–238.

E. Fjeldberg, E. A. Holm, A. D. Rollett and K. Marthinsen: Materials Science Forum, 2012, vol. 715–716, pp. 930–935.

D. McLean: Nature, 1953, vol. 172, pp. 300–301.

M. Winning, G. Gottstein, and L. S. Shvindlerman: Acta Materialia, 2001, vol. 49, pp. 211–219.

M. Winning, G. Gottstein, and L. S. Shvindlerman: Materials Science and Engineering A, 2001, vol. A317, pp. 17–20.

M. Winning, G. Gottstein, and L. S. Shvindlerman: Acta Materialia, 2002, vol. 50, pp. 353–363.

J. W. Cahn, Y. Mishin, and A. Suzuku: Philosophical Magazine, 2006, vol. 86, pp. 1–11.

J. W. Cahn and J. E. Taylor: Acta Materialia, 2004, vol. 52, pp. 4887–4898.

W.F. Gale and T.C. Totemeier, eds: Smithells Metals Reference Book, 18th ed., Elsevier, Butterworth-Heinemann, Burlington, MA, 2004, pp. 4–39.

G. Gottstein and L. S. Shvindlerman. Grain Boundary Migration in Metals. CRC Press, New York, 1999.

J. Weertman: Trans. Metall. Soc. AIME, 1960, vol. 218, pp. 207–218.

J. Weertman: Journal of Applied Physics, 1957, vol. 28, pp. 362–364.

J. Weertman: Journal of Applied Physics, 1957, vol. 28, pp. 1185–1189.

Acknowledgments

The authors gratefully acknowledge the National Science Foundation for experimental equipment supported under grant DMR-9974476 and research support under Grants DMR-0605731 and DMR-1105468. The authors thank Osram Sylvania for providing composition analysis services. The authors extend special thanks to Dr. James Ciulik for significant technical contributions to this study. EMT thanks Prof. Thomas R. Bieler for useful discussions on through-thickness texture variations in sheet materials.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 3, 2011.

Rights and permissions

About this article

Cite this article

Worthington, D.L., Pedrazas, N.A., Noell, P.J. et al. Dynamic Abnormal Grain Growth in Molybdenum. Metall Mater Trans A 44, 5025–5038 (2013). https://doi.org/10.1007/s11661-013-1865-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1865-x