Abstract

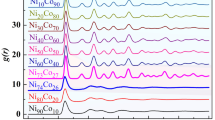

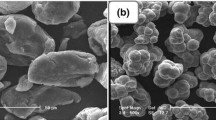

The nanocrystallization and amorphization processes in Ni60Nb40 and Ni60Zr40 binary alloys during mechanical alloying (MA) were studied in detail. The mechanical alloying behavior of these alloy systems was compared with respect to the rate of refinement of grain size, ultimate grain size, and rate of amorphization reaction. For both compositions, MA leads to the refinement of grain size and enhancement of internal strain, followed by the amorphization reaction. The higher melting temperature metal Nb exhibits smaller grain size and greater internal strain, although the Ni and Nb grain size approach a similar value of ~15 nm after 20 hours of milling time. The refinement of grain size and enhancement of internal strain was observed to occur with a slower rate during MA of Ni60Zr40 alloy compared to Ni60Nb40 alloy. In all cases, an ultrafine layered structure with a typical thickness of 30 nm, containing nanoscale size grains with a typical size of 15 nm and a high density of dislocations, develops prior to the amorphization reaction. This observation suggests that numerous high-speed diffusion paths such as grain boundaries and dislocations are necessary to allow a high diffusion rate at low temperature and therefore permits the amorphization reaction to take place kinetically. The Ni-Zr system is a better glass former in MA than Ni-Nb system; i.e., the start time of amorphization reaction for Ni60Zr40 was about half that for Ni60Nb40. These results were discussed in terms of physical and chemical characteristics of the constituent elements of the alloy systems. Furthermore, the thermodynamically stable phase in each system was predicted using a semi-empirical Miedema model, and the results were compared with the structure formed in MA of Ni-Zr and Ni-Nb powder mixture.

Similar content being viewed by others

Abbreviations

- ΔG :

-

Gibbs free energy change

- ΔH :

-

chemical enthalpy change

- ΔS :

-

chemical entropy change

- X :

-

mole fraction

- V :

-

molar volume

- n ws :

-

electron density

- \( f_{B}^{A} \) :

-

degree to which A is surrounded by B

- \( f_{A}^{B} \) :

-

degree to which B is surrounded by A

- K :

-

bulk modulus

- G :

-

shear modulus

- H :

-

hardness

- Q * :

-

activation energy for diffusion

- Z :

-

number of valence electrons

- E :

-

structural energy

- T :

-

temperature

- D :

-

grain size

- b :

-

Burger vector

- r o :

-

mean nearest-neighbor distance

- P, Q, and R * :

-

empirical constants

- λ :

-

X-ray wavelength

- β :

-

diffraction peak width at half-maximum intensity

- γ :

-

empirical parameter

- α :

-

topological disorder parameter

- ε :

-

internal strain

- θ :

-

diffraction angle

- \( \Upphi^{ * } \) :

-

work function of constituent elements

- A, B :

-

element

- sol:

-

solution

- m:

-

melting point

- chem:

-

chemical

- e:

-

elastic

- str:

-

structural

- min:

-

minimum

- am:

-

amorphous

- ref:

-

reference

References

C.Y. Chung, M. Zhu, and C.H. Man: Intermetallics, 2002, vol. 10, pp. 865–71.

M. Zhu, M. Qi, A.Q. He, H.X. Sui, and W.G. Liu: Acta Metall. Mater., 1994, vol. 42, pp. 1893–99.

J. Eckert, J.C. Holzer, C.E. Kril, and W.L. Johnson: J. Mater. Res., 1992, vol. 7, pp. 1751–61.

A. Benghalem and D.G. Morris: Acta Metall. Mater., 1994, vol. 42, pp. 4071–81.

H.J. Fecht, E. Hellstern, Z. Fu, and W.L. Johnson: Adv. Powder Metall., 1989, vol. 1, pp. 111–22.

H.J. Fecht, E. Hellstern, Z. Fu, and W.L. Johnson: Metall. Trans. A, 1990, vol. 21, pp. 2333–37.

F.A. Mohamed and Y. Xun: Mater. Sci. Eng. A, 2003, vol. 354, pp. 133–39.

F.A. Mohamed: Acta Mater., 2003, vol. 51, pp. 4107–19.

F.A. Mohamed and Y. Xun: Mater. Sci. Eng. A, 2003, vol. 358, pp. 178–85.

C.C. Koch: Nanostruct. Mater., 1993, vol. 2, pp. 109–29.

C. Suryanarayana: Prog. Mater. Sci., 2001, vol. 46, pp. 1–184.

R.B. Schwarz, R.R. Petrich, and C.K. Saw: J. Non-Cryst. Solids., 1985, vol. 76, pp. 281–302.

W.L. Johnson: Prog. Mater. Sci., 1986, vol. 30, pp. 81–134.

W.L. Johnson: Mater. Sci. Eng., 1988, vol. 97, pp. 1–13.

I. Manna, P. Nandi, B. Bandyopadhyay, K. Ghoshray, and A. Ghoshray: Acta Mater., 2004, vol. 52, pp. 4133–42.

C.C. Koch, O.B. Cavin, C.G. McKamey, and J.O. Scarbrough: Appl. Phys. Lett., 1983, vol. 43, pp. 1017–19.

F. Petzoldt, B. Scholz, and H.D. Kunze: Mater. Lett., 1987, vol. 5, pp. 280–84.

E. Hellstern and L. Schultz: Appl. Phys. Lett., 1986, vol. 48, pp. 124–26.

G.K. Williamson and W.H. Hall: Acta Metall., 1953, vol. 1, pp. 22–31.

S. Bera, S. Mazumdar, M. Ramgopal, S. Bhattacharyya, and I. Manna: J. Mater. Sci., 2007, vol. 42, pp. 3645–50.

A.R. Miedema, F.R. de Boer, and R. Boom: J. Phys. B, 1981, vol. 103, pp. 67–81.

L.M. Di, H. Bakker, P. Barczy, and Z. Gacsi: Acta Metall. Mater., 1993, vol. 41, pp. 2923–32.

H. Bakker: J. Less-Common Met., 1985, vol. 105, pp. 129–38.

P.K. Ray, M. Akinc, and M.J. Kramer: J. Alloys Compd., 2010, vol. 489, pp. 357–61.

R.F. Zhang and B.X. Liu: Appl. Phys. Lett., 2002, vol. 81, pp. 1219–21.

A.R. Miedema, P.F. de Chatel, and F.R. de Boer: Physica, 1980, vol. 100B, pp. 1–28.

N.K. Mukhopadhyay, D. Mukherjee, S. Dutta, R. Manna, D.H. Kim, and I. Manna: J. Alloy. Compd., 2008, vol. 457, pp. 177–84.

P.I. Loeff, A.W. Weeber, and A.R. Miedema: J. Less-Common Met., 1988, vol. 140, pp. 299–305.

T. Mousavi, F. Karimzadeh, and M.H. Abbasi: Mater. Lett., 2009, vol. 63, pp. 786–88.

G.J. Vander-Kolk, A.R. Miedema, and A.K. Niessen: J. Less-Common Met., 1988, vol. 145, pp. 1–17.

N. Gao and W.S. Lai: J. Phys. Condens. Matter, 2007, vol. 19, pp. 1–12.

E. Hellstern, H.J. Fechet, Z. Fu, and W.L. Johnson: J. Appl. Phys., 1989, vol. 65, pp. 305–10.

T. Nasu, K. Nagaoka, S. Takahashi, E. Suganuma, T. Sekiuchi, T. Fukunago, and K. Suzuki: Mater. Trans. JIM, 1989, vol. 30, pp. 620–23.

R. Bormann and R. Busch: New Materials by Mechanical Alloying Techniques, DGM Informationsgesellschaft, Oberursel, Germany, 1988, pp. 73–78.

S.K. Pabi, D. Das, T.K. Mahapatra, and I. Manna: Acta Mater., 1998, vol. 46, pp. 3501–10.

O. Haruyama and N. Asahi: J. Alloys Compd., 1993, vol. 194, pp. 361–71.

J. Eckert, L. Schultz, E. Hellstern, and K. Urban: J. Appl. Phys., 1988, vol. 64, pp. 3224–28.

F. Petzoldt, B. Scholz, and H.D. Kunze: Mater. Sci. Eng., 1988, vol. 97, pp. 25–29.

R. Bruning, Z. Altounnian, J.O. Strom-Olsen, and L. Schultz: Mater. Sci. Eng., 1988, vol. 97, pp. 317–20.

C. Suryanarayana, T. Klassen, and E. Ivanov: J. Mater. Sci., 2011, vol. 46, pp. 6301–15.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted August 24, 2012.

Rights and permissions

About this article

Cite this article

Enayati, M.H., Dastanpoor, E. Comparative Study of Mechanical Alloying Induced Nanocrystallization and Amorphization in Ni-Nb and Ni-Zr Systems. Metall Mater Trans A 44, 3984–3998 (2013). https://doi.org/10.1007/s11661-013-1717-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1717-8