Abstract

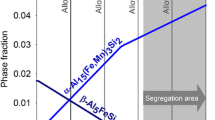

Microstructural evolution and solidification behavior of Al-5 wt pct Mg-1.5 wt pct Si-0.6 wt pct Mn-0.2 wt pct Ti alloy have been investigated using high-pressure die casting. Solidification commences with the formation of primary α-Al phase in the shot sleeve and is completed in the die cavity. The average size of dendrites and fragmented dendrites of the primary α-Al phase formed in the shot sleeve is 43 μm, and the globular primary α-Al grains formed inside the die cavity is at a size of 7.5 μm. Solidification inside the die cavity also forms the lamellar Al-Mg2Si eutectic phase and the Fe-rich intermetallics. The size of the eutectic cells is about 10 μm, in which the lamellar α-Al phase is 0.41 μm thick. The Fe-rich intermetallic compound exhibits a compact morphology and is less than 2 μm with a composition of 1.62 at. pct Si, 3.94 at. pct Fe, and 2.31 at. pct Mn. A solute-enriched circular band is always observed parallel to the surface of the casting. The band zone separates the outer skin region from the central region of the casting. The solute concentration is consistent in the skin region and shows a general drop toward the center inside the band for Mg and Si. The peak of the solute enrichment in the band zone is much higher than the nominal composition of the alloy. The die casting exhibits a combination of brittle and ductile fracture. There is no significant difference on the fracture morphology in the three regions. The band zone is not significantly detrimental in terms of the fracture mechanism in the die casting. Calculations using the Mullins and Sekerka stability criterion reveal that the solidification of the primary α-Al phase inside the die cavity has been completed before the spherical α-Al globules begin to lose their stability, but the α-Al grains formed in the shot sleeve exceed the limit of spherical growth and therefore exhibit a dendritic morphology.

Similar content being viewed by others

References

E.J. Vinarcik: High Integrity Die Casting Processes, Wiley, New York, 2003.

H.L. MacLean, L.B. Lave: Prog. Energy Combust. Sci., 2003, vol. 29 (1), pp1-69.

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. DeSmet, A. Haszler, A. Vieregge: Mater. Sci. Eng. A, 2000, vol. A280 (1), pp.37-49.

R.J. Orsato, P. Wells: J. Cleaner Prod., 2007, vol. 15(11-12), pp.994-1006.

J.T. Staley, D.J. Lege: J. De Physique IV, 1993, vol.3, pp.179-90.

A. Tharumarajah: Resour. Conserv. Recycl., 2008, vol.52, pp.1185-89.

D. Carle, G. Blount: Mater. Des., 1999, vol. 20 (5), pp. 267-72.

European Aluminium Association: Aluminium in Cars, European Aluminium Association, 2008.

S. Ji, D. Watson, Z. Fan, M. White, Mater. Sci. Eng. A, 2012, vol. 556, pp 824–33.

D. Apelian: Aluminium Cast Alloys: Enabling Tools for Improved Performance. North American Die Casting Association, Wheeling, IL, USA, 2009, pp.1-68.

P. Krug, H. Koch, and R. Klos: Magsimal-25—A new High-Ductility Die Casting Alloy for Structural Parts in Automotive Industry, www.dgm.de/download/tg/523/523_0784.pdf.

M. Hosseinifar, D.V. Malakhov: Metall. Mater. Trans. A, 2011, vol.42A, pp.825-33.

Y.L. Liu, S.B. Kang: J. Mater. Sci., 1997, vol.32, pp.1443-47.

S.A. Kori, M.S. Prabhudev, T.M. Chandrashekharaiah: Trans. Indian Inst. Met., 2009, vol.62, pp.353-56.

L. Yu, X. Liu, Z. Wang, X. Bian: J. Mater. Sci. 2005, vol.40, pp.3865-71.

S. Otarawanna, C.M. Gourlay, H.I. Laukli, A.K. Dahle: Metall. Mater. Trans. A, 2009, vol. 40A, pp.1645-59.

J. Jie, C. Zou, H. Wang, Z. Wei: Materials Letters, 2010, vol. 64, pp.869-71.

R. Kimura, H. Hatayama, K. Shinozaki, I. Murashima, J. Asada, M. Yoshida: J. Mater. Process. Technol., 2009, vol. 209 (1), pp.210-15.

A. Hamasaiid, M.S. Dargusch, C.J. Davidson, S. Tovar, T. Loulou, F. Rezai-Aria, G. Dour: Metall. Mater. Trans. A, 2007, vol. 38A, pp.1303-15.

A.K. Dahle, D.H. StJohn: Acta Mater. 1999, vol. 47, pp. 31-41.

V. Raghavan: J. Phase Equilib. Diffus., 2007, vol. 28, pp.189-91.

P. Beeley, Foundry Technology, 2nd ed., Oxford: Butterworth-Heinemann; 2001.

W.W. Mullins, R.F. Sekerka: J. Appl. Phys., 1963, vol.34, pp.323-29.

W.W. Mullins, R.F. Sekerka: J. Appl. Phys., 1964, vol.35, pp.444-51.

R.F. Sekerka: J. Appl. Phys., 1965, vol.36, pp.264-68.

D.P. Woodruff: The Solid–Liquid Interface. Cambridge: Cambridge University Press; 1973.

E.A. Brandes, G.B. Brook: Smithells Metals Reference Book. 7th ed. Oxford: Butterworth; 1992.

A.L. Greer, A.M. Bunn, A. Tronche, P.V. Evans, D.J. Bristow: Acta Mater., 2000, vol. 48, pp.2823-35.

M.H. Burden, J.D. Hunt: J. Cryst. Growth, 1974, vol. 22, pp.99-108.

J.D. Hunt, S.Z. Lu: Metall. Mater. Trans. A, 1996, vol. 27A, pp.611-23.

K. Keslioglu, M. Gunduz, H. Kaya, E. Cadırl: Mater. Lett., 2004, vol.58, pp.3067-71.

T.F. Bower, H.D. Brody, M.C. Flemings: Trans. AIME., 1966, vol.236, pp.624-33.

S-P. Li, S-X. Zhao, M-X. Pan, D-Q. Zhao, X-C. Chen, O.M. Barabash: J. Mater. Sci., 2001, vol.36, pp.1569-75.

J. Cambell (2003) Castings, 2nd ed., Elsevier Butterworth-Heinemann, Oxford.

K.A. Jackson, J.D. Hunt: Trans. Metall. Soc. AIME., 1966, vol.236, pp.1129-42.

R. Grugel, W. Kurz: Metall. Trans. A, 1987, vol.18, pp.1137-42.

U. Böyüka, S. Enginb, N. Maraşlı: Materials Characterization, 2011, vol.62 (9), pp.844-51.

H. Kaya, E. Cadirli, M. Gündüz: J. Mater. Process. Technol., 2007, vol.183 (2-3), pp.310-20.

E.P. Whelan, C.W. Haworth: J. Aust. Inst. Met., 1967, vol.12, pp.77-126.

R. Trivedi, J.T. Mason, J.D. Verhoeven, W. Kurz: Metall. Trans. A, 1991, vol.22A, pp.2523-33.

A. Moore and R. Elliott: in Proc. Conf. Iron and Steel, Ins. Publ., Brighton, 1967, pp. 167–74.

E. Cadirli, H. Kaya, M. Gunduz: Mater. Res. Bull., 2003, vol. 38, pp.1457-76.

E. Cadirli, A. Ulgen, M. Gunduz: Mater. Trans. JIM., 1999, vol. 40, pp.989-96.

R. Trivedi, P Magnin, W Kurz: Acta Metall. 1987, vol. 35, pp.971-80.

W. Kurz and R. Trivedi: Metall. Trans. A, 1991, vol.22A, 3051–57.

L. Wang, M. Makhlouf, D. Apelian: Int. Mater. Rev., 1995, vol. 40, pp. 221-38.

L.F. Mondolfo: Aluminium Alloys: Structure and Properties, London, Butterworths, 1976.

S.G. Shabestari: Mater. Sci. Eng. A, 2004, vol.383A, pp.289-300.

G. Gustafsson, T. Thorvaldsson, G.L. Dunlop: Metall. Trans. A, 1986, vol. 17A, pp.45-52.

S.G. Shabestari, M. Mahmudi, M. Emami, J. Campbell: Int. J. Cast Met. Res.., 2002, vol. 15, pp.17-24.

J.L. Jorstad: Die Casting Eng., 1986, vol. 11/12, pp.23-27.

L.F. Mondolfo: Manganese in Aluminium Alloys, The Manganese Centre, Paris, 1978.

A. Couture: A.F.S. Int. Cast Met. J., 1981, vol.6(4), pp.9-17.

Acknowledgments

The authors wish to thank EPSRC and JLR for the financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted April 25, 2012.

Rights and permissions

About this article

Cite this article

Ji, S., Wang, Y., Watson, D. et al. Microstructural Evolution and Solidification Behavior of Al-Mg-Si Alloy in High-Pressure Die Casting. Metall Mater Trans A 44, 3185–3197 (2013). https://doi.org/10.1007/s11661-013-1663-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-013-1663-5