Abstract

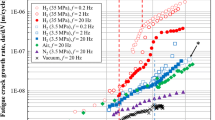

Threshold stress intensity factors were measured in high-pressure hydrogen gas for a variety of low alloy ferritic steels using both constant crack opening displacement and rising crack opening displacement procedures. Thresholds for crack extension under rising displacement, K THi, for crack extension under constant displacement, \( K_{\text{THi}}^{*} \), and for crack arrest under constant displacement K THa, were identified. These values were not found to be equivalent, i.e. K THi < K THa < \( K_{\text{THi}}^{*} \). The hydrogen assisted fracture mechanism was determined to be strain controlled for all of the alloys in this study, and the micromechanics of strain controlled fracture are used to explain the observed disparities between the different threshold measurements. K THa and K THi differ because the strain singularity of a stationary crack is stronger than that of a propagating crack; K THa must be larger than K THi to achieve equivalent crack tip strain at the same distance from the crack tip. Hydrogen interacts with deformation mechanisms, enhancing strain localization and consequently altering both the nucleation and growth stages of strain controlled fracture mechanisms. The timing of load application and hydrogen exposure, i.e., sequential for constant displacement tests and concurrent for rising displacement tests, leads to differences in the strain history relative to the environmental exposure history and promotes the disparity between \( K_{\text{THi}}^{*} \) and K THi. K THi is the only conservative measurement of fracture threshold among the methods presented here.

Similar content being viewed by others

Notes

The tensile stress ahead of the crack tip is nearly identical for stationary and propagating cracks in perfectly plastic materials; however differences do increase with the degree of strain hardening.[22] Nonetheless, this difference remains relatively small compared with the difference found between the strain fields of stationary and propagating cracks.

Quantitative analyses should consider that the value of ε Hf may not be identical for constant displacement and rising displacement test conditions.

This same scenario was also simulated by applying finite element modeling[20] to the elastic–plastic response of the 4130X (641 MPa) WOL specimen. For the same applied front-face displacement, the total J was calculated as 183 kJ/m2, which is within 10 pct of the total J estimated from the experimental load vs displacement data.

References

R.P. Gangloff: Comprehensive Structural Integrity, vol. 6, I. Milne, R.O. Ritchie and B. Karihaloo, Eds., Elsevier Science, New York, NY, 2003, pp. 31-101

A.W. Thompson and I.M. Bernstein: in Advances in Corrosion Science and Technology, vol. 7: Hydrogen-Assisted Environmental Fracture, M.G Fontana, R.W. Staehle, eds., Plenum Publishing Corporation, New York, 1980, pp. 53–175.

H.K. Birnbaum, I.M. Roberston, P. Sofronis and D. Teter: Proceedings of the Second International Conference on Corrosion–Deformation Interactions, CDI 96, T. Magnin ed., Woodhead Publishing Limited, Cambridge, 1997.

I.M. Bernstein: Mater. Sci. Eng., 1970, vol. 6, pp. 1-19.

J.P. Hirth: Metall. Trans. A, 1980, vol. 11A, pp. 861-890.

R.A. Oriani: Annu. Rev. Mater. Sci., 1978, vol. 8, pp. 327-357.

H.G. Nelson: Hydrogen Embrittlement Testing, ASTM STP 543, ASTM, Philadelphia PA, 1974, pp. 152-169.

P. McIntyre: Hydrogen Degradation in High Strength Steels, R.A. Oriani, J.P. Hirth and M. Smialowski, eds., Noyes Publications, New Jersey, 1985, pp. 763–98.

A.W. Loginow and E.H. Phelps: Corrosion, 1975, vol. 31, pp. 404-412.

M. Dadfarnia, P. Sofronis, B.P. Somerday, D.K. Balch, P. Schembri and R. Melcher: Eng. Fract. Mech., 2011, vol. 78, pp. 2429-2438.

W.G. Clark and J.D. Landes: Stress Corrosion – New Approaches, ASTM STP 610, ASTM, Philadelphia PA, 1976, pp. 108-127.

R.P. Gangloff: Hydrogen Effects on Materials Behavior and Corrosion Deformation Interactions, N.R. Moody, A.W. Thompson, R.E. Ricker, G.W. Was, and R.H. Jones, eds., The Minerals Metals and Materials Society, Warrendale, PA, 2003, pp. 477–97.

ASTM E1681-03, Annual Book of ASTM Standards, ASTM International, West Conshohocken, PA, 2003.

R.P. Wei and S.R. Novak: J. Test. Eval., 1987,vol. 15, pp.38-75.

J.H. Underwood, W.A. Van Der Sluys, and G.N. Vigilante: Technical Report ARCCB-TR-97016, US Army Armament Research, Development and Engineering Center, Benet Laboratories, Watervliet, NY, 1997.

G.N. Vigilante, J.H. Underwood, D. Crayon, S. Tauscher, T. Sage and E. Troiano: Fatigue and Fracture: 28 th Volume, ASTM STP 1321, J.H. Underwood, B.D. Macdonald and M.R. Mitchell, eds., ASTM, West Conshohocken, PA, 1997, pp. 602–16.

H.P. Seifert and S. Ritter: J. Nucl. Mater., 2008, vol. 372, pp. 114-131.

J. Heldt and H.P. Seifert: Nucl. Eng. Des., 2001, vol. 206, pp. 57-89.

EIGA Doc 100/03/E: Hydrogen Cylinders and Transport Vessels, European Industrial Gases Association, Brussels, Belgium, 2003.

K.A. Nibur, B.P. Somerday, C. San Marchi, J.W. Foulk III, M. Dadfarnia, P. Sofronis, G.A. Hayden: Sandia Report SAND2010-4633, Sandia National Laboratories, Livermore, CA 2010.

W.J. Drugan, J.R. Rice, and T.-L. Sham: J. Mech. Phys. Solids, 1982, vol. 30, pp. 447-473.

M.R. Begley, J.A. Begley and C.M. Landis: Gaseous Hydrogen Embrittlement of Materials in Energy Technologies Volume 2: Mechanics, Modelling and Future Developments, R.P. Gangloff and B.P. Somerday, eds., Woodhead Publishing Limited, Cambridge, UK, 2011, pp. 286–325.

B.P. Somerday, L.M. Young and R.P. Gangloff: Fatigue Fract. Eng. Mater. Struct., 2000, vol. 23, pp. 39-58.

M.M. Hall Jr.: Corros. Sci., 2008, vol. 50, pp. 2902-2905.

W.W. Gerberich and S. Chen: Environment-Induced Cracking of Metals: Proceedings of the First International Conference on Environment-Induced Cracking of Metals, R.P. Gangloff and M.B. Ives, eds., NACE, Houston TX, 1988, pp. 167–87.

S.H. Chen, Y. Katz and W.W. Gerberich: Philos. Mag. A, 1991, vol. 63, pp. 131-155.

M.W. Perra: Environmental Degradation of Engineering Materials in Hydrogen, M.R. Louthan, R.P. McNitt, and R.D. Sisson, eds., VPI Press, Blacksburg, VA, 1981 pp. 321–33.

ASTM E1820-09: Annual Book of ASTM Standards, ASTM International, West Conshohoken, PA, 2009.

ASTM E1737-96: Annual Book of ASTM Standards, ASTM International, West Conshohocken, PA, 1996.

R.L.S. Thomas, J.R. Scully, and R.P. Gangloff: Metall. Trans. A, 2003, vol. 34A, pp. 327-344.

R. Zawierucha and K. Xu: Proceedings of Materials Science and Technology 2005: Materials for the Hydrogen Economy, TMS, Warrendale, PA, 2005, pp. 79-90.

C. San Marchi, B.P. Somerday, K.A. Nibur, D.G. Stalheim, T. Boggess, S. Jansto: Proceedings of the ASME 2010 Pressure Vessels and Piping Division/K-PVP Conference, PVP2010-25825, ASME, New York, NY, 2010.

Y. Takeda and C.J. McMahon. Metall. Trans. A, 1981, vol. 12, pp. 1255-1266.

J.E. Costa and A.W. Thompson: Metall. Trans. A, 1981, vol. 12A, pp. 761-771.

M. Gao, M. Lu, and R.P. Wei: Metall. Trans. A, 1984, vol. 15A, pp. 735-746.

T.D. Lee, T. Goldenberg, and J.P. Hirth: Metall. Trans. A, 1979, vol. 10A, pp. 199-208.

C.D. Beachem: J. Basic Eng. (Trans. ASME Series D), 1965, vol. 87, pp. 299-306.

H.C. Burghard, Jr., and N.S. Stoloff: Electron Fractography, ASTM STP 436, ASTM, Philadelphia, PA, 1968, pp. 32-58.

A.W. Thompson: Fatigue Fract. Eng. Mater. Struct., 1996, vol. 19, pp. 1307-1316.

C.D. Beachem and R.M.N. Pelloux: Fracture Toughness Testing and its Applications, STP 381, ASTM, Philadelphia PA, 1965, pp. 210-244.

Electron Fractography: ASTM STP 436, C.D. Beachem, ed., ASTM International, Philadelphia, PA, 1967.

M.L. Martin, J.A. Fenske, G.S. Liu, P. Sofronis, and I.M. Robertson: Acta Mater., 2011, vol. 59, pp. 1601-1606.

M.R. Bache, W.J. Evans, and H.M. Davies: J. Mater. Sci. 1997, vol. 32, pp. 3435-3442.

M.Q. Jiang, Z. Ling, J.X. Meng and L.H. Dai: Philos. Mag. 2008, vol. 88, pp. 407-426.

K. Tokaji, M. Kamakura, Y. Ishiizumi, N. Hasegawa: Int. J. Fatigue, 2004, vol. 26, pp. 1217-1224.

C.J. McMahon, Jr.: Hydrogen Effects in Metals, I.M. Bernstein and A.W. Thompson, eds., The Metallurgical Society of AIME, Warrendale, PA, 1981, pp. 219–34.

F. Nakasato and I.M. Bernstein: Metall. Trans., 1978, vol. 9A, pp. 1317-1326.

A.W. Thompson and I.M. Bernstein: Advances in Research on the Strength and Fracture of Materials, Vol. 2A, Proceedings of the Fourth International Conference on Fracture, D.M.R. Taplin, ed., Permagon Press, Oxford, 1977, pp. 249–54.

M.L. Martin, I.M. Robertson and P. Sofronis: Acta Mater., 2011, vol. 59, pp. 3680-3687.

D. Kwon and R.J. Asaro: Metall. Trans. A, 1990, vol. 21A, pp. 117-134.

I.M. Robertson: Eng. Fract. Mech., 1999, vol. 64, pp. 649-673.

I.M. Robertson, M.L. Martin, and J.A. Fenske: Gaseous Hydrogen Embrittlement of Materials in Energy Technologies, R.P. Gangloff and B.P. Somerday, eds., Woodhead Publishing Limited, Cambridge, UK, 2011, pp. 166–206.

K.A. Nibur, D.F. Bahr, B.P. Somerday: Acta Mater., 2006, vol. 54, pp. 2677-2684.

K.A. Nibur, B.P. Somerday, D.K. Balch, and C. San Marchi: Acta Mater., 2009, vol. 57, pp. 3795-3809.

H.E. Hanninen, T.C. Lee, I.M. Robertson and H.K. Birnbaum: J. Mater. Eng. Perform., 1993, vol. 2, pp. 807-817.

R.O. Ritchie and A.W. Thompson: Metall. Trans. A, 1985, vol. 16A, pp. 233-248.

R.H. Dean and J.W. Hutchinson: Fracture Mechanics: Twelfth Conference, ASTM STP 700, American Society for Testing and Materials, West Conshohocken, PA. 1980, pp. 383-405.

J.R. Rice and E.P. Sorensen: J. Mech. Phys. Solids, 1978, vol. 26, pp. 163-186.

O.A. Onyewuenyi and J.P. Hirth: Metall. Trans. A, 1983, vol. 14A, pp. 259-269.

N.F. Mott and F.R.N. Nabarro: Physical Society Bristol Conference Report, 1948, pp. 1–19.

A.H. Cottrell: Philos. Mag. Lett., 2002, vol. 82, pp. 65-70.

M.M. Hall, Jr.: Report CONF-9505335-1, Alloy 600 Experts Meeting sponsored by the Electric Power Research Institute, Electric Power Research Institute, 1993.

S. Wang, Y. Zhang, and W. Chen: J. Mater. Sci., 2001, vol. 36, pp. 1931-1938.

C.G. Park, K.S. Shin, J. Nagakawa and M. Meshii: Scripta Metall. 1980, vol. 14, pp. 279-284.

A. Barnoush, M. Zamanzade, and H. Vehoff: Scripta Metall. 2010, vol. 62, pp. 242-245.

H.K. Birnbaum and P. Sofronis: Mater. Sci. Eng., 1994, vol. A176, pp. 191-202.

E. Sirois and H.K. Birnbaum: Acta Metall. Mater. 1992, vol. 40, pp. 1377-1385.

R.M. Rieck, A. Atrens and I.O. Smith: Metall. Trans. A, 1989, vol. 20A, pp. 889-895.

A. Oehlert and A, Atrens: Acta Metall. Mater., 1994, vol. 42, pp. 1493-1508.

R.N. Parkins: Stress Corrosion Cracking – The Slow Strain-Rate Technique, ASTM STP 665, G.M. Ugiansky and J.H. Payer, eds., ASTM, Philadelphia, PA, 1979, pp. 5–25.

K.A. Nibur, B.P. Somerday, C. SanMarchi and D.K. Balch: Proceedings of 2008 ASME Pressure Vessels and Piping Division Conference, PVP2008-61298, 2008.

V. Vitek: Int. J. Fract., 1977, vol. 13, pp. 481-501.

J.W. Hutchinson: J. Mech. Phys. Solids, 1968, vol. 16, pp. 13-31.

J.R. Rice and G.F. Rosengren: J. Mech. Phys. Solids, 1968, vol. 16, pp. 1-12.

R.O. Ritchie, W.L. Server, and R.A. Wullaert: Metall. Trans. A, 1979, vol. 10A, pp. 1557-1570.

J.R. Rice: Fracture: an Advanced Treatise – Vol. 2: Mathematical Fundamentals, H. Liebowitz, ed., Academic Press, 1968, Chapter 3, pp. 191–311.

F.A. McClintock and G.R. Irwin: Fracture Toughness Testing and its Applications, ASTM STP 381, American Society for Testing and Materials, Chicago, 1965, pp. 84-113.

J.R. Rice, W.J. Drugan and T.-L. Sham: Fracture Mechanics: Twelfth Conference, ASTM STP 700, American Society for Testing and Materials, Philadelphia, PA, 1980, pp. 189-221.

J.R. Rice: Mechanics of Solids: The Rodney Hill 60 th Anniversary Volume, H.G. Hopkins and M.J. Sewell, eds., Pergamon Press, Oxford, England, 1982, pp. 539–62.

K.S. Chan: Metall. Trans. A, 1990, vol. 21A, pp. 69-80.

W.W. Gerberich, D.L. Davidson, and M. Kaczorowski: J. Mech. Phys. Solids, 1990, vol. 38, pp. 87-113.

Y.-C. Gao and K.-C. Hwang: Advances in Fracture Research; Proceedings of the Fifth International Conference on Fracture, U.K., 1982, pp. 669–82.

R. Irani: Hydrogen Embrittlement: How It Was Resolved in the 1980’s, Presentation from ISO TC58/WG7, Gas Cylinder Compatibility, Atlanta GA, 29 Sept. 2008.

T.L. Anderson: Fracture Mechanics Fundamentals and Applications, Third Edition, Taylor and Francis, Boca Raton FL, 2005.

ASTM E399-06: Annual Book of ASTM Standards, ASTM International, West Conshohocken, PA, 2006.

J.A. Joyce and R.L. Tregoning: Fatigue and Fracture Mechanics: 30th Volume, ASTM STP 1360, ASTM, West Conshohocken PA, 2000, pp. 357-376.

HKS: Abaqus Version 6.7, Theory Manual. Hibbit, Karlsson, and Sorensen, Providence, RI, 2007.

G.R. Irwin: Structural Mechanics, Proceedings of the First Symposium of Naval Structural Mechanics, J.N. Goodier and N.J. Hoff, eds., Permagon Press, Oxford, 1960, pp. 557–94.

Acknowledgments

Sandia National Laboratories is a multi-program laboratory managed and operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Corporation, for the U.S. Department of Energy’s National Nuclear Security Administration under contract DE-AC04-94AL85000. The experimental work presented here has been supported by the US Department of Energy Fuel Cell Technologies program through the Safety, Codes and Standards sub-program element. PS and MD were supported by the US Department of Energy under Grant GO15045. The assistance of Ken Lee and Jeff Campbell in the experimental work as well as Andy Gardea, Jeff Chames and Ryan Nishimoto in metallography and microscopy is gratefully acknowledged. The authors additionally thank Gary Hayden (CP Industries) and John Felbaum (Fiba Technologies) for providing technologically relevant steels for testing.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted March 5, 2012.

Appendix A: K-Dominance at Crack Initiation and Crack Arrest

Appendix A: K-Dominance at Crack Initiation and Crack Arrest

1.1 K-Dominance at Crack Initiation

For the lower-strength steels in this study, both K app and K THa were relatively high (Figures 3 and 4). As a result, significant plasticity is expected at the crack tip in these lower-strength steels, and the potential implication of this plasticity on the crack-driving forces during the onset of subcritical cracking and at crack arrest must be addressed. Specifically, extensive plasticity can compromise rigorous application of linear-elastic fracture mechanics and the presumption of a highly constrained crack tip.

All values of K app and K THa presented here are calculated using linear-elastic fracture mechanics, however very few of the WOL specimens tested in this study met the specimen size requirements specified by ASTM E1681 for small-scale yielding and plane strain, which requires:

where B, a, and b refer to the specimen thickness, crack length, and remaining ligament (W-a), respectively, σo is the yield strength and K I is the stress-intensity factor. Upon initial loading, only the high-strength SA372 grade L (1053 MPa) specimens met the specimen size criteria, i.e., Eq. [A1] was satisfied with K I = K app for this steel heat. At crack arrest, the SA372 grade L (1053 MPa) and DOT-3T specimens also met the specimen size criteria, i.e., Eq. [A1] was satisfied with K I = K THa for these steel heats. None of the other, lower-strength steel specimens satisfied Eq. [A1] at either initial loading or crack arrest. While meeting the specimen size requirements in Eq. [A1] generally ensures plane-strain constraint under small-scale yielding, these conditions are not necessarily compromised in the WOL specimens if Eq. [A1] is not satisfied.

It has been well documented that the specimen size criterion for plane strain is overly conservative for the thickness, B, dimension when appropriate side-grooves are designed into the specimens.[84] Side-grooves enhance through-thickness constraint, effectively creating plane-strain conditions along the entire crack front, except near the end points where the presence of the free surfaces relaxes the constraint. In the absence of side-grooves, the region of reduced constraint extends further from the surfaces and fracture within this region occurs as 45 deg shear fracture (forming “shear lips”), whereas fracture within the highly constrained, plane-strain region appears flat. When the region of shear fracture contributes to a significant portion of the total crack front, elevated fracture measurements result. However, if the regions of shear fracture are a small fraction of the total crack front, plane-strain fracture can be assumed.[84] Shear lips were insignificant along the entire crack length for all WOL specimens tested in this study, suggesting that plane-strain conditions prevailed for all K levels between K THa and K app.

It has been argued that the dimensional requirements for small-scale yielding, i.e., limits on crack length, a, and uncracked ligament, b, in Eq. [A1], were extended to ASTM E1681 and other standards from ASTM E399,[85] in which these criteria were intended to apply only to the 95 pct secant method for measurement of K Ic. As a result, failure to satisfy the criteria does not necessarily indicate a violation of small-scale yielding.[86] Rather, it has been suggested that the relative contributions of the elastic and plastic components of the J-integral is a better means to assess small-scale yielding. If the plastic component of J is small relative to the elastic component, then linear-elastic fracture mechanics, i.e., small-scale yielding, is a valid assumption.

The small-scale yielding assumption during initial loading of the WOL specimens was evaluated by estimating J from experimental load vs crack-opening displacement data. Actual load vs displacement data for the 4130X (641 MPa) specimen loaded to the highest value of K app is shown in Figure 10. These data, measured from the load-tup and clip gage during initial loading, reveal deviations from linear behavior. Such deviation from linear behavior was most pronounced for the lower-strength steels loaded to high values of K app and was not observed for the higher-strength steels. In Figure 10, the deviation from linearity is such that the value of load inferred from the final displacement measurement assuming linear-elastic loading is nearly 40 pct higher than the load measured from the load-tup. Based on the load vs displacement data in Figure 10, the plastic component of J was calculated from ASTM E1820 using the relationships for the CT specimen, which is expected to closely approximate the WOL specimen. The calculations demonstrate that the elastic component of J was 87 kJ/m2 and the plastic component was 112 kJ/m2.Footnote 3 This plastic component is large relative to the elastic component, suggesting that globally elastic, small-scale yielding behavior is not the case (consistent with the grossly non-linear load vs displacement curve in Figure 10); however, the specimen crack tip is expected to be highly constrained according to the dimensional requirements for plane strain and J-dominance provided by ASTM E1820:

Load vs crack-opening displacement recorded during initial loading of 4130X WOL specimen. Dashed line shows behavior under linear-elastic loading conditions inherent to the calculation of K app, whereas the solid line shows actual applied load which was used to calculate J app. Fortuitously, K app ~ K Japp

Equation [A2] requires that the thickness, B, and uncracked ligament, b, only equal 3.1 mm, criteria that the WOL specimen easily satisfies. The above analysis was conducted for 4130X specimens, since these tests represented an extreme combination of low yield strength and high K app, and thus exhibited the most severe plastic deformation during loading. In fact, few other specimens exhibited any noticeable deviation from linearity in the measured load vs displacement trace. For the higher-strength steels and those specimens with lower values of K app, the assumption of small-scale yielding during loading is valid.

The lowest-strength steels, e.g., 4130X, do not exhibit small-scale yielding during loading, therefore the relevance of the linear-elastic fracture mechanics quantity K app for characterizing the remote crack-driving force is in question. For those cases in which plasticity caused deviations from linear-elastic loading, the value of K app calculated from the front-face displacement assuming linear-elastic behavior (e.g., 199 MPa \( \sqrt {\text{m}} \) for 4130X) is fortuitously a good representation of the elastic-plastic loading condition, since K Japp equals 212 MPa \( \sqrt {\text{m}} \) (calculated from the J app = 183 kJ/m2 determined above using experimental load vs displacement data); i.e., K app ≈ K Japp. Therefore, it appears that K app calculated using the linear-elastic fracture mechanics relationship in Eq. [1] provides an approximate representation of remote crack-driving force for the entire range of elastic-plastic behavior exhibited by the specimens in this study. It must be noted that this result is not a general conclusion, and the coincidence of K app and K Japp must be verified before assuming that it applies to lower-strength steels or to different specimen geometries.

1.2 K-Dominance at Crack Arrest

As described in Section III–A, subcritical cracking progressed through a large fraction of the specimen width in most WOL specimens, such that the final crack length-to-width (a/W) ratio of the arrested crack was typically greater than 0.8. Consequently, the presumption that the linear-elastic stress-intensity factor, K, uniquely characterized the crack-tip stress and strain fields at crack arrest was in question. Whereas the extent of crack-tip plasticity during loading of the WOL specimens could be assessed using experimental load vs displacement data to estimate the relative plastic and elastic contribution to the J-integral, a similar evaluation at crack arrest required numerical simulation since unloading which occurs as the cracks propagate violates the proportional loading assumption that underlies the validity of the J-integral. The finite element method was used to assess K-dominance at the arrested crack tip.

To address this issue, numerical calculations were conducted using Abaqus Standard[87] to demonstrate that K governed the crack-tip fields in WOL specimens that represented the experiments. Finite strain elastoplastic deformation was implemented in the simulations. In the elastic regime, the material was assumed to be linear and isotropic and in the plastic regime to obey normality, with von Mises yielding and isotropic hardening. Data from uniaxial tension tests (provided by the material supplier) were used to construct the flow stress as a function of plastic strain. The WOL specimen was discretized with eight-noded isoparametric plane-strain elements. Deep cracks (a/W = 0.81 and 0.94) were loaded to crack-mouth-opening displacements comparable to those used in the experiments. It is noted that contour plots of the effective plastic strain in the neighborhood of the crack tip can be used to discern whether plasticity is confined to the crack tip. Two approaches for evaluating K-dominance were considered, each of which assessed the condition of an arrested crack near the back face of the specimen. The effect of crack propagation history on the crack-tip fields was not considered.

The first approach to assess K-dominance was to evaluate the extent of plasticity through calculations of the J-integral. The domain integral approach on contours around the crack tip was utilized to calculate the value of the J-integral. The associated stress-intensity factor can be determined from

The criterion for K-dominance is based on comparing this value of K J to the stress-intensity factor calculated numerically for the WOL specimen under the assumption of purely elastic specimen response.

The second approach to assess K-dominance was to compare the stress profiles as calculated ahead of the blunting crack tip in the full-field simulation of the WOL specimen with those prevailing at the crack tip under small-scale yielding (SSY) conditions. The SSY domain was loaded under plane strain by remote displacements associated with the stress-intensity factor K I obtained from the elastic analysis of the WOL specimen. Thus, the asymptotic displacements of the Irwin singular linear elastic field[88] were prescribed remotely from the crack tip. These displacements were imposed incrementally at a constant stress-intensity factor rate toward the final value of K I, which was selected to be consistent with experimentally measured values of K THa.

Full-field simulations of the crack-tip stresses and strains were conducted by modeling a WOL specimen of SA372 grade J (717 MPa) having a stationary crack at a/W = 0.81. The front-face displacement was V FF = 1.26 mm which resulted in K THa = 109 MPa \( \sqrt {{m}} \) (as determined using Eq. [1]); these values directly replicate measurements from one of the specimens in the experimental study. The elastic finite element analysis gave K = 119 MPa \( \sqrt {\text{m}} \), while K J from elastic-plastic analysis was 116 MPa \( \sqrt {\text{m}} \). The similarity of the calculated K and K J values indicates that small-scale yielding prevailed. In addition to comparing these remote-loading parameters, Figure 11 shows the crack-opening stress, σyy, along the axis of symmetry ahead of the crack tip for the representative WOL specimen from SA372 grade J. Superposed on the same figure is the opening stress as furnished by the SSY solution. The strong agreement between these two solutions confirms that there is K-dominance at crack arrest. In summary, the FEM analysis suggests that K I accurately describes the crack-tip fields even at these long final crack lengths near the back face of the specimen. This conclusion is consistent with the comparison of results from experiments on straight-notched and chevron-notched WOL specimens, in which K THa was not dependent on a/W.

Comparison of the crack-tip opening stress, σ yy , on the plane of symmetry ahead of the crack in the WOL specimen with the small-scale yielding solution. Flow properties representative of the SA372 grade J (717 MPa) steel were used. The simulation for the WOL specimen was done with the specimen loaded to a crack-opening displacement V FF = 1.26 mm and the crack tip positioned at a/W = 0.81

Rights and permissions

About this article

Cite this article

Nibur, K.A., Somerday, B.P., Marchi, C.S. et al. The Relationship Between Crack-Tip Strain and Subcritical Cracking Thresholds for Steels in High-Pressure Hydrogen Gas. Metall Mater Trans A 44, 248–269 (2013). https://doi.org/10.1007/s11661-012-1400-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1400-5