Abstract

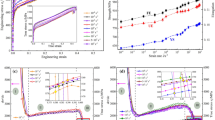

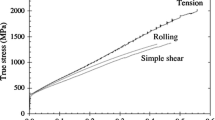

A systematic investigation of the evolution of deformation microstructure and texture of twinning-induced plasticity (TWIP) steel during cold rolling has been carried out using electron backscatter diffraction and X-ray diffraction, as well as viscoplastic self-consistent simulations. It is found that extensive twinning leads to the formation of the strong Brass {110}〈112〉 and Goss {110}〈001〉 components in TWIP steel even at low strains. At higher reduction, heterogeneous deformation contributes to further strengthening of Brass (Bs) component. The origin and stability of Bs component as well as the impact of the evolution of texture and microstructure on mechanical anisotropy is further explored using viscoplastic self-consistent simulations.

Similar content being viewed by others

References

E.A. Brandes and G.B. Brook: Smithells Metals Reference Book, 7th ed., Butterworth-Heinemann, Oxford, U.K., 1992.

E.R. Parker: Materials Data Book for Engineers and Scientists, McGraw-Hill, New York, NY, 1967.

O. Grassel, L. Cruger, G. Frommyer, and L.W. Meyer: Int. J. Plast., 2000, vol. 16, pp. 1391–409.

C. Scott, N. Guelton, S. Allain, M. Farral, and P. Cugy: Proc. M. S. & T. 05, Pittsburgh, PA, 2005.

S. Asgari, El-Danf, S.R. Kalidindi, and R.D. Doherty: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 1781–95.

S. Allain, J.P. Chateau, O. Bouaziz, S. Migot, and M. Guelton: Mater. Sci. Eng. A, 2004, vols. 387–389, pp. 158–62.

K. Sato, M. Ichinose, Y. Hirotsu, and Y. Inoue: ISIJ Int., 1989, vol. 29, pp. 868–77.

Y.G. Kim, J.M. Han, and J.S. Lee: Mater. Sci. Eng. A, 1989, vol. 114, pp. 51–59.

S. Cotes, M. Sad, and A. Fernandez Guillermet: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 1957–69.

R.E. Scharamm and R.P. Reed: Metall. Trans. A, 1975, vol. 6A, pp. 1345-51.

Y. Lu, D. Molodov, and G. Gottstein: ISIJ Int., 2011, vol. 51, pp. 812–17.

K. Pawlik: Phys. Status Solidi B, 1986, vol. 134, pp. 477–83.

TSL-OIM v5.2 Users Manual, EDAX Inc., Mahwah, NJ.

R.A. Lebensohn and C.N. Tome: Acta Metall. Mater., 1993, vol. 41, pp. 2611–24.

C.N. Tomé, G.R. Canova, and U.F. Kocks: Acta Metall., 1984, vol. 32, pp. 1637–53.

R.E. Smallman and D. Green: Acta Metall., 1964, vol. 12, pp. 145–54.

S. Vercammen, B. Blanpain, B.C. De Cooman, and P. Wollants: Acta Mater., 2004, vol. 52, pp. 2005–12.

L. Bracke, K. Verbeken, L. Kestens, and J. Penning: Acta Mater., 2009, vol. 57, pp. 1512–24.

B. Qin: Masters Dissertation, Pohang University of Science and Technology (POSTECH), Pohang, South Korea, July 2007.

G. Wasserman: Z. Metallkd., 1963, vol. 54, pp. 61–65.

J. Hirsch, K. Lücke, and M. Hatherly: Acta Metall., 1988, vol. 36, pp. 2905–27.

T. Leffers and A. Grum-Jensen: Trans. AIME, 1968, vol. 242, pp. 314–19.

T. Leffers and R.K. Ray: Prog. Mater. Sci., 2009, vol. 54, pp. 351–96.

Y. Zhong, F. Yin, T. Sakaguchi, K. Nagai, and K. Yang: Acta Mater., 2007, vol. 55, pp. 2747–56.

Acknowledgments

This study was carried out as an extension to a research program funded by Tata Steel, Jamshedpur, India. The constant encouragement received from Prof. R. K. Ray and Dr. D. Bhattacharjee (both Tata Steel R&D) is gratefully acknowledged. The facilities set up at the Indian Institute of Science, Bangalore, namely, the Institute X-ray facility and Advanced Facility for Microscopy and Microanalysis (AFMM) was utilized in this study. Thanks are due to Prof. I Samajdar for providing access to the National facility for OIM at IIT Bombay and to R. Madhavan for his help in carrying out EBSD.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 13, 2012.

Rights and permissions

About this article

Cite this article

Gurao, N.P., Kumar, P., Bhattacharya, B. et al. Evolution of Crystallographic Texture and Microstructure During Cold Rolling of Twinning-Induced Plasticity (TWIP) Steel: Experiments and Simulations. Metall Mater Trans A 43, 5193–5201 (2012). https://doi.org/10.1007/s11661-012-1346-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-012-1346-7