Abstract

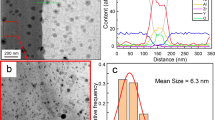

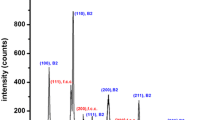

Fe100–x C x melts (x = 18 to 24) can be cast under B2O3 flux into solids of interconnected network morphology, with a wavelength in the submicron range. There are two major constituent subnetworks, which are a brittle Fe3C subnetwork and a ductile αFe subnetwork. The Fe100–x C x network alloys, therefore, are white cast iron of novel microstructure. Fe100–x C x specimens of x = 18 to 21 are ductile and the yield strength can be as large as ~3200 MPa. Fe100–x C x specimens of x = 22 to 24 are in the regime of a ductile-to-brittle transition. The compressive strength is high, at ~2700 MPa. Microstructural analysis indicates that the ultrafine network morphology and the ductile αFe subnetwork are responsible for the ductility exhibited in Fe100–x C x network alloys of x = 17 to 21. They are also responsible for the high compressive strength in Fe100–x C x network alloys of x = 22 to 24.

Similar content being viewed by others

Notes

BUEHLER is a trademark of Lake Bluff, IL.

INSTRON is a trademark of Norwood, MA.

TEFLON is a trademark of E.I. Du Pont de Nemours & Co., Inc., Wilmington, DE.

References

M.F. Ashby and D.R.H. Jones: Engineering Materials 2, An Introduction to Microstructures, Processing and Design, 3rd ed., Elsevier, Oxford, United Kingdom, 2006, pp. 128–31.

C.P. Tabrett, I.R. Sare, and M.R. Ghomashchi: Int. Mater. Rev., 1996, vol. 41, pp. 59–82.

D.R. Askeland: The Science and Engineering of Materials, 3rd ed., PWS Publishing Company, Boston, MA, 1994, pp. 365–73.

C.M. Ho, C.C. Leung, Y.L. Yip, S.W. Mok, and H.W. Kui: Metall. Mater. Trans. A, 2010, vol. 41A, pp. 3443–51.

Binary Alloy Phase Diagrams, 2nd ed., ASM INTERNATIONAL, Materials Park, OH, 1996.

C.F. Lau and H.W. Kui: J. Appl. Phys., 1990, vol. 67, pp. 3181–84.

D. Tabor: The Hardness of Metals, Oxford University Press, Oxford, United Kingdom, 1951, p. 6.

J.W. Cahn: J. Chem. Phys., 1965, vol. 42, pp. 93–99.

M.F. Ashby and D.R.H. Jones: Engineering Materials 2, An Introduction to Microstructures, Processing and Design, 3rd ed., Elsevier, Oxford, United Kingdom, 2006, p. 198.

J.W. Cahn: Trans. TMS-AIME, 1968, vol. 242, pp. 166–80.

J.E. Hilliard: Phase Transformations, ASM, Metals Park, OH, 1970, pp. 497–561.

H.S. Chen and D. Turnbull: Acta Metall., 1969, vol. 17, pp. 1021–31.

C.P. Chou and D. Turnbull: J. Non-Cryst. Solids, 1975, vol. 17, pp. 169–88.

C.P. Chou and F. Spaepen: Acta Metall., 1975, vol. 23, pp. 609–13.

H.S. Chen: Mater. Sci. Eng., 1976, vol. 23, pp. 151–54.

L.E. Tanner and R. Ray: Scripta Metall., 1980, vol. 14, pp. 657–62.

C.O. Kim and W.L. Johnson: Phys. Rev. B, 1981, vol. 23, pp. 143–47.

C.W. Yuen and H.W. Kui: J. Mater. Res., 1998, vol. 13, pp. 3034–42.

K.L. Lee and H.W. Kui: J. Mater. Res., 1999, vol. 14, pp. 3653–62.

D. Nagahama, T. Ohkubo, and K. Hono: Scripta Mater., 2003, vol. 49, pp. 729–34.

S.V. Madge, H. Rosner, and G. Wilde: Scripta Mater., 2005, vol. 53, pp. 1147–51.

T. Wada, D. Louzguine-Luzgin, and A. Inoue: Scripta Mater., 2007, vol. 57, pp. 901–04.

J. Eckert and S. Scudino: Materials Processing Handbook, Boca Raton, FL, 2007, pp. 6.6–6.7.

E.S. Park, E.Y. Jeong, J.K. Lee, J.C. Bae, A.R. Kwon, A. Gebert, L. Schultz, H.J. Chang, and D.H. Kim: Scripta Mater., 2007, vol. 56, pp. 197–200.

N. Mattern, G. Goerigk, U. Vainio, M.K. Miller, T. Gemming, and J. Eckert: Acta Mater., 2009, vol. 57, pp. 903–08.

Selected Values of Thermodynamic Properties of Metals and Alloys, R. Hultgren, R.L. Orr, P.D. Anderson, and K.K. Kelly, eds., John Wiley and Sons, New York, NY, 1963, p. 565.

J. Chipman: Metall. Trans., 1972, vol. 3, pp. 55–64.

J. Lacaze and B. Sundman: Metall. Trans. A, 1991, vol. 22A, pp. 2211–17.

M.E. Schlessinger and Q. Xiang: J. Alloys Compd., 2001, vol. 321, pp. 242–47.

Y.L. Yip and H.W. Kui, Department of Physics, Chinese University of Hong Kong, Shatin, N.T., Hong Kong, P.R. China, unpublished research, 2009.

G.E. Dieter: Mechanical Metallurgy, 3rd ed., McGraw-Hill, Singapore, 1988, pp. 189–91.

M.A. Meyers and K.K. Chawla: Mechanical Behavior of Materials, Prentice Hall, Englewood Cliffs, NJ, 1999, p. 327.

M.F. Ashby and D.R.H. Jones: Engineering Materials 2, 3rd ed., Elsevier, Oxford, United Kingdom, 2006, p. 223.

Acknowledgments

We thank Ms. Y.L. Yip for technical assistance and useful discussions. We thank Mr. K.M. Woo and Miss S.Y. Ku for measuring the R values of the Fe-C network specimens.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted September 21, 2010.

Rights and permissions

About this article

Cite this article

HO, C.M., KUI, H.W. Ductile and High Strength White Cast Iron of Ultrafine Interconnected Network Morphology. Metall Mater Trans A 42, 3826–3837 (2011). https://doi.org/10.1007/s11661-011-0772-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0772-2