Abstract

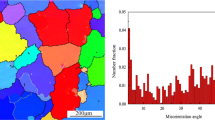

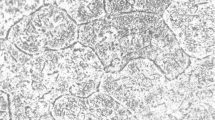

The objective of the present work was to investigate the dynamic recrystallization phenomenon of a new Al-2.8Cu-1.4Li alloy. Isothermal compression experiments were carried out at a temperature of 643 K to 723 K (370 °C to 450 °C), strain rate of 0.001 to 1 s−1, and deformation degree of 20 to 50 pct to determine material parameters for empirical models. Different holding times from 10 to 30 minutes were set to obtain the effect of initial grain size on microstructural evolution. Based on the results of stress-strain curves and metallographic analysis, the constitutive model and dynamic recrystallization mathematical model of Al-2.8Cu-1.4Li alloy were derived. The coupled thermomechanical finite element method integrated with the dynamic recrystallization model was used to simulate the change of microstructure during hot upsetting. Good agreement between the predicted results and experimental results was obtained, which demonstrated that the dynamic recrystallization model can be successfully used to predict microstructural evolution during hot working for Al-2.8Cu-1.4Li alloy.

Similar content being viewed by others

References

M.F. Abbod, C.M. Sellars, A. Tanaka, D.A. Linkens, and M. Mahfouf: Mater. Sci. Eng. A, 2008, vol. 491, pp. 290–96.

A.J. Brand, S. Kalz, and R. Kopp: Comp. Mater. Sci., 1996, vol. 7, pp. 242–46.

S.I. Kim and K.C. Yoo: Mater. Sci. Eng. A, 2001, vol. 311, pp. 108–13.

H.J. McQueen and J.E. Hockett: Metall. Trans., 1970, vol. 1, pp. 2997–3004.

M.E. Wahabi, L. Gavard, F. Montheillet, J.M. Cabrera, and J.M. Prado: Acta Mater., 2005, vol. 53, pp. 4605–12.

J.T. Yeom, C.S. Lee, J.H. Kim, and N.K. Park: Mater. Sci. Eng. A, 2007, vols. 449–451, pp. 722–26.

Y.S. Na, J.T. Yeom, N.K. Park, and J.Y. Lee: J. Mater. Process. Technol., 2003, vol. 141, pp. 337–42.

Z. Peng and T. Sheppard: Modell. Simul. Mater. Sci. Eng., 2004, vol. 12, pp. 43–57.

C.M. Sellars and J.A. Whiteman: Met. Sci., 1979, vol. 13, pp. 187–94.

T. Senuma and H. Yada: Proc. 7th Risø Int. Symp. on Metallurgy and Materials Science, Roskilde, Denmark, 1986, pp. 547–52.

Y. Saito, T. Enami, and T. Tanaka: Trans. Iron Steel Inst. Jpn., 1985, vol. 25, pp. 1146–55.

M.A. Munon-Morris, I. Gutierrez-Urrutia, N. Calderon, and D.G. Morris: Mater. Sci. Eng. A, 2008, vol. 442, pp. 268–75.

Y.L. Chen, J.F. Li, H.J. Lv, S.C. Li, Z.Q. Zheng, Y.W. Zhang, and X.H. Zhang: Trans. Nonferrous Met. Soc. China, 2007, vol. 17, pp. s271–s275.

S. Kobayashi, S.I. Oh, and T. Altan: Metal Forming and the Finite Element Method, Oxford University Press, Oxford, United Kingdom, 1989.

C.M. Sellars: Acta Metall., 1966, vol. 14, pp. 1136–38.

Y.S. Jang, D.C. Ko, and B.M. Kim: J. Mater. Process. Technol., 2000, vol. 101, pp. 85–94.

J.R. Cho, H.S. Jeong, D.J. Cha, W.B. Bae, and J.W. Lee: J. Mater. Process. Technol., 2005, vol. 160, pp. 1–8.

DEFORMTM-2D V9.0 User Manual, Scientific Forming Technologies Corporation, Columbus, OH, 2006.

Acknowledgments

The authors gratefully acknowledge the support given by the Ministry of Industry and Information Technology of the People’s Republic of China (Grant No. 2009ZX04014-082). This work was also supported by the State Key Laboratory of Materials Processing and Die & Mould Technology, Huazhong University of Science and Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted July 29, 2010.

Rights and permissions

About this article

Cite this article

Deng, L., Wang, X.Y., Xia, J.C. et al. Microstructural Modeling and Simulation of Al-2.8Cu-1.4Li Alloy during Elevated Temperature Deformation. Metall Mater Trans A 42, 2509–2515 (2011). https://doi.org/10.1007/s11661-011-0657-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-011-0657-4