Abstract

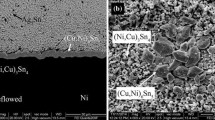

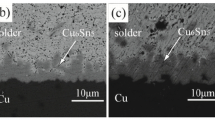

The interface microstructures as well as the rate kinetics of dissolution and intermetallic compound (IMC) layer formation were investigated for couples formed between molten 63Sn-37Pb (wt pct) solder and 99.9 pct Pd sheet. The solder bath temperatures were 488 K to 593 K (215 °C to 320 °C), and the immersion times were 5, 15, 30, 60, 120, and 240 seconds. The predominant IMC phases were Pd(Sn, Pb)4, PdSn4, and PdSn3. The IMC layer microstructure contained these phases and varying amounts of solder Pb- and Sn-rich phases. Isolated Pd-Sn needles appeared in the solder field at temperatures and times of ≥563 K (290 °C) and ≥30 seconds, respectively. Palladium dissolution was largely monotonic as a function of time and solder temperature, except for a sharp decline at 593 K (320 °C). The dissolution rate kinetics over 488 K to 563 K (215 °C to 290 °C) were represented by the At n exp(−ΔH/RT) equation. The values of n and ΔH were 0.67 ± 0.19 and 48 ± 20 kJ/mol, respectively, suggesting that a combination of interface reaction and solid-state mass transport processes controlled dissolution. The IMC layer grew monotonically with time and solder temperature, except at 593 K (320 °C) where growth dropped off significantly. The IMC growth rate kinetics over 488 K to 563 K (215 °C to 290 °C) exhibited values of n and ΔH equal to 0.88 ± 0.10 and 64 ± 10 kJ/mol, respectively, indicating a combination of interface reaction and solid-state diffusion processes. The extents of Pd dissolution and IMC layer development were significantly greater for molten Sn-Pb solder than the Pb-free Sn-Ag-Cu solder (Part I study) at a given test temperature.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

Although the term “layer” is less than descriptive of the morphology of the IMC in this and other examples of Sn-Pb/Pd couples, it will continue to be used for a consistent discussion.

References

P.T. Vianco: Circuit World, 1998, vol. 25, pp. 6–24.

The State of the Art in Pb-Free Soldering Technology, 2nd ed., P. Vianco, ed., Surface Mount Technology Association, Edina, MN, 2004, CD-ROM.

D. Abbott, R. Brook, N. McClelland, and J. Wiley: IEEE Trans. Comp., Hybrids, Mfg. Technol., 1991, vol. 14, pp. 567–72.

D. Romm and D. Abbott: Surf. Mount Technol., 1999, Jan., pp. 86–91.

K. Banerji and E. Bradley: Proc. Surface Mount Int. Conf., SMTA, Edina, MN, 1994, pp. 584–95.

W. Bader: Weld. J., 1969, vol. 48, pp. 551-s–557-s.

S. Vaynman, G. Ghosh, and M. Fine: J. Electron. Mater., 1998, vol. 27, pp. 1223–28.

D.W. Finley, U. Ray, I. Artaki, P. Vianco, S. Shah, A. Reyes, and M. Haq: Proc. Surface Mount Int. Conf., SMTA, Edina, MN, 1995, pp. 941–53.

R. Pratt, E. Stromweld, and D. Quesnel: Sandia Report No. SAND93-7104, Sandia National Laboratories, Albuquerque, NM, 1993.

G. Ghosh: Mater. Trans. A, 1999, vol. 30A, pp. 5–19.

G. Ghosh: J. Electron. Mater., 1998, vol. 27, pp. 1154–60.

G. Ghosh: Acta Mater., 2000, vol. 48, pp. 3719–38.

B. Kobe and N. McIntyre: Acta Mater., 2002, vol. 50, pp. 4667–76.

Y. Wang and K. Tu: Appl. Phys. Lett., 1995, vol. 67, pp. 1069–71.

Binary Alloy Phase Diagrams, T. Massalski, ed., ASM INTERNATIONAL, Materials Park, OH, 1986, vol. 2, p. 1848.

Binary Alloy Phase Diagrams, T. Massalski, ed., ASM INTERNATIONAL, Materials Park, OH, 1986, vol. 2, p. 1834.

P. Vianco: Environmentally Friendly Electronic Manufacturing—Pb Free Technology and Application, J. Hwang, ed., Electrochemical Pub., Ltd., British Isles, United Kingdom, 2001, p. 436.

P. Vianco, J. Martin, R. Wright, and P. Hlava: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1551–61.

Acknowledgments

The authors thank Richard Grant for contributions to the EPMA and Donald Susan for his thorough review of this manuscript. Sandia is a multiprogram laboratory operated by Sandia Corporation, a Lockheed Martin Company, for the United States Department of Energy’s National Nuclear Security Administration under Contract No. DE-AC04-94AL85000.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 23, 2009.

Rights and permissions

About this article

Cite this article

Vianco, P.T., Rejent, J.A., Zender, G.L. et al. Dissolution and Interface Reactions between Palladium and Tin(Sn)-Based Solders: Part II. 63Sn-37Pb Alloy. Metall Mater Trans A 41, 3053–3064 (2010). https://doi.org/10.1007/s11661-010-0379-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-010-0379-z