Abstract

AISI 301 and E-BRITE stainless steels were subjected to low-temperature (743 K) carburization experiments using a commercial technology developed for carburization of 316 austenitic stainless steels. The AISI 301 steel contained ~40 vol pct ferrite before carburization but had a fully austenitic hardened case, ~20-μm thick, and a surface carbon concentration of ~8 at. pct after treatment; this “colossal” paraequilibrium carbon supersaturation caused an increase in lattice parameter of ~3 pct. The E-BRITE also developed a hardened case, 12- to 18-μm thick, but underwent a more modest (~0.3 pct) increase in lattice parameter; the surface carbon concentration was ~10 at. pct. While the hardened case on the AISI 301 stainless steel appeared to be single-phase austenite, evidence for carbide formation was apparent in X-ray diffractometer (XRD) scans of the E-BRITE. Paraequilibrium phase diagrams were calculated for both AISI 301 and E-BRITE stainless steels using a CALPHAD compound energy-based interstitial solid solution model. In the low-temperature regime of interest, and based upon measured paraequilibrium carbon solubilities, more negative Cr-carbon interaction parameters for austenite than those in the current CALPHAD data base may be appropriate. A sensitivity analysis involving Cr-carbon interaction parameters for ferrite found a strong dependence of carbon solubility on relatively small changes in the magnitude of these parameters.

Similar content being viewed by others

Notes

E-BRITE is a registered trademark of ATI Allegheny Ludlum Corp., Brackenridge, PA.

We do not suggest that graphite will precipitate in either a binary Fe-carbon alloy or a stainless steel on carburization. Rather, it is more convenient to calculate the paraequilibrium diagrams to follow, assuming metastable equilibrium with atmospheric carbon of unit activity, i.e., the activity of graphite, rather than metastable equilibrium with a paraequilibrium carbide whose free energy is unknown.

References

G.M. Michal, F. Ernst, H. Kahn, Y. Cao, F. Oba, N. Agarwal, and A.H. Heuer: Acta Mater., 2006, vol. 54, pp. 1597–1606.

G.M. Michal, F. Ernst, and A.H. Heuer: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 1819–24.

F.J. Martin, E.J. Lemieux, T.M. Neubauer, R.A. Bayles, P.M. Natishan, H. Kahn, G.M. Michal, and A.H. Heuer: Electrochem. Solid-State Lett., 2007, vol. 10, pp. C-76–C-78.

K. Farrell, E.D. Specht, J. Pang, L.R. Walker, A. Rar, and J.R. Mayotte: J. Nucl. Mater., 2005, vol. 343, pp. 123–33.

P.L. Gruzin, V.G. Kastogonov, and P.A. Platanov: Dokl. Akad. Nauk SSR, 1955, vol. 100, pp. 1069–72.

A.W. Bowen and G.M. Leak: Metall. Trans., 1970, vol. 1, pp. 1695–1700.

B.J. Lee: CALPHAD, 1992, vol. 16, pp. 121–49.

R.R. Judd: Ph.D. Thesis, Carnegie Institute of Technology, Pittsburgh, PA, 1966.

W.D. Cullity: Elements of X-Ray Diffraction, Addison-Wesley Publishing Col, Inc., Reading, MA, 1956, pp. 391–96.

F. Ernst, A. Avishai, H. Kahn, X. Gu, G.M. Michal, and A.H. Heuer: Metall. Mater. Trans. A, 2009, vol. 40A, DOI 10.1007/s11661-009-9854-9

K. Natesan and T.F. Kassner: Metall. Trans., 1973, vol. 4, pp. 2557–66.

H. Wada: Metall. Trans. A, 1985, vol. 16A, pp. 1479–90.

J.-O. Anderson: Metall. Trans. A, 1988, vol. 19A, pp. 627–36.

B. Venkatnaman and J.P. Neumann: Bull. Alloy Phase Diagrams, 1990, vol. 11, pp. 152–59.

J.J. Poubeau and J. Bigot: Acta Metall., 1985, vol. 33, pp. 1137–41.

W.H. Smith: Trans. AIME, 1957, vol. 209, pp. 47–49.

T. Christiansen and M.A.J. Somers: Surface Eng., 2005, vol. 21, pp. 445–55.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation given at the “International Conference on Surface Hardening of Stainless Steels,” which occurred October 22–23, 2007 during the ASM Heat Treating Society Meeting in Cleveland, OH under the auspices of the ASM Heat Treating Society and TMS.

Appendices

Appendix I

Preferential sputtering can cause an effective surface segregation in multicomponent systems. Of specific concern in steels is the much slower sputtering rate of carbon compared to the metal atoms which generates a near-surface region enriched in carbon. The method used to convert the surface carbon concentration as atomic fraction \( X_{\rm C}^{S} \) measured by Auger spectroscopy or ESCA to the bulk carbon concentration, \( X_{\rm C}^{B} , \) is outlined as follows (\( X_{M}^{S} \) and \( X_{M}^{B} \) are the corresponding metal atom fractions.) After a period of sputtering, the ratio of carbon to metal atoms in the near surface region compared to the bulk is given by Eq. [A1].

Experience in our laboratory suggests that the sputtering factor f cm between carbon and the metal atoms is ~6, corresponding to a considerable enrichment of the near-surface region with carbon. Due to the extremely small escape depth of ions, the enriched near-surface region only extends from the surface to one layer below the surface.

The escape depths for the carbon signal for Auger spectroscopy and ESCA are ~0.85 nm (4.4 atomic layers) and ~1.70 nm (7.8 atomic layers), respectively. The carbon concentration measured by these techniques are the average of the carbon concentration, \( X_{\rm C}^{S} , \) in the first two atomic layers and \( X_{\rm C}^{B} \) in the remaining atomic layers. The measured carbon concentration \( X_{\rm C}^{M} \) is a function of \( X_{\rm C}^{S} \) and \( X_{\rm C}^{B} \) as shown in Eq. [A2]

where n is the escape depth in units of atomic layers for the form of spectroscopy being employed. Inasmuch as \( X_{\rm C}^{S} + X_{M}^{S} = X_{\rm C}^{B} + X_{M}^{B} = 1, \) Eq. [A1] can be rearranged to yield \( X_{\rm C}^{S} \) as a function of \( X_{\rm C}^{B} . \) Inserting the expression for \( X_{\rm C}^{S} \) into Eq. [A2] establishes the functional relationship between \( X_{\rm C}^{M} \) and \( X_{\rm C}^{B} , \) as shown in Eq. [A3].

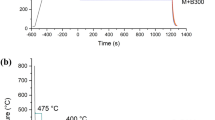

Equation [A3] was employed to convert carbon concentrations measured by either Auger spectroscopy or ESCA to the bulk carbon concentrations plotted in Figures 1(d) and 2(c).

Appendix II

A sensitivity analysis was conducted to explore the effect of changes in CALPHAD parameters on the solubility of carbon in bcc and fcc Cr-Fe alloys and the relative stability of the bcc and fcc phases of Cr-Fe alloys as a function of their carbon concentrations. Our recent paraequilibrium carburization studies[1,2] revealed that Cr-carbon interactions in the fcc phase, as presently represented in the CALPHAD data base through the work of Lee,[7] are insufficiently exothermic at low temperatures. At temperatures of ~750 K, extrapolation of the dilute solution model of Natesan and Kassner for fcc Fe-Cr-Ni-carbon alloys shows much better agreement with the experimental carbon solubilities. To increase the applicability of the Natesan and Kassner model for assessment of fcc phase stability, CALPHAD parameters were fitted to their model over the temperature range 500 to 1000 K. A multivariable best-fit procedure was employed, with the added restriction that the free energy of formation of the CrC (rock salt) carbide remain high enough that the phase would not appear on the Cr-C binary phase diagram. The parameters that were obtained are listed in Table AI, where they are compared with those of Lee.[7]

The CALPHAD parameters for the bcc phase are much larger than those for the fcc phase. The two parameters by Lee[7] were decreased by nominally 50 kJ (Table AI), and the resulting changes in the predicted solubility of carbon in pure bcc chromium and Fe-Cr alloys containing less than 7 at. pct chromium were compared with the experimental work of Venkatraman and Neumann[14] and Wada,[12] respectively, as discussed in Section IV–C. These more exothermic bcc parameters were then used to model the solubility of carbon and phase stability in AISI 301 and EBRITE stainless steels.

Rights and permissions

About this article

Cite this article

Michal, G.M., Gu, X., Jennings, W.D. et al. Paraequilibrium Carburization of Duplex and Ferritic Stainless Steels. Metall Mater Trans A 40, 1781–1790 (2009). https://doi.org/10.1007/s11661-009-9826-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-9826-0