Abstract

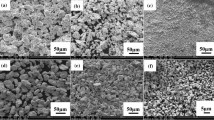

A series of high-carbon Cr-based hard-facing alloys were successfully fabricated on a substrate of 0.45 pct C carbon steel by gas tungsten arc welding (GTAW) process using various alloy fillers with chromium and chromium carbide, CrC (Cr:C = 4:1) powders. These claddings were designed to observe hypoeutectic, near-eutectic, and hypereutectic structures with various (Cr,Fe)23C6 and (Cr,Fe)7C3 carbides at room temperature. According to X-ray diffraction (XRD), field emission scanning electron microscopy (FESEM), and optical microscopy (OM), in 3.8 pct C cladding, the microstructure consisted of the primary carbides with outer shells (Cr,Fe)23C6 surrounding (Cr,Fe)7C3 cores and [α + (Cr,Fe)23C6] eutectic structures. In 5.9 pct C cladding, the composite comprised primary (Cr,Fe)7C3 as the reinforcing phase and [α + (Cr,Fe)7C3] eutectic structures as matrix. Various morphologies of carbides were found in primary and eutectic (Cr,Fe)7C3 carbides, which included bladelike and rodlike (with a hexagonal cross section). The 5.9C cladding with great amounts of primary (Cr,Fe)7C3 carbides had the highest hardness (approximately HRC 63.9) of the all conditions.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

References

ASM International Handbook Committee: ASM Handbook, 10th ed., ASM INTERNATIONAL, Materials Park, OH, 1990, vol. 18, pp. 758–68.

I.M. Hutchings: Tribology: Friction and Wear of Engineering Materials, Elsevier Limited, Cambridge, 1992, pp. 133–47.

S.O. Yılmaz: Surf. Coat. Technol., 2006, vol. 201, pp. 1568–75.

C. Fan, M.C. Chen, C.M. Chang, and W. Wu: Surf. Coat. Technol., 2006, vol. 201, pp. 908–12.

C.W. Kuo, C. Fan, S.H. Wu, and W. Wu: Mater. Trans., 2007, vol. 48, pp. 2324–28.

P.Q. La, Q.J. Xue, and W.M. Liu: Wear, 2001, vol. 249, pp. 94–100.

S. Frangini, A. Masci, and A.D. Bartolomeo: Surf. Coat. Technol., 2002, vol. 149, pp. 279–86.

P.Q. La, Q.J. Xue, W.M. Liu, and S.R. Yang: Wear, 2000, vol. 240, pp. 1–8.

A.F. Zhang, J.D. Xing, L. Fang, and J.Y. Su: Wear, 2004, vol. 257, pp. 198–204.

H. Berns: Wear, 2003, vol. 254, pp. 47–54.

J.D. Xing, Y.M. Gao, E.Z. Wang, and C.G. Bao: Wear, 2002, vol. 252, pp. 755–60.

S. Aso, S. Goto, Y. Komatsu, and W. Hartono: Wear, 2001, vol. 250, pp. 511–17.

A.G. Blake, A.A. Mangaly, M.A. Everett, and A.H. Hammeke: SPIE Conference Proceedings, 1st ed., SPIE Publications, Bellingham, WA, 1988, pp. 56–61.

E. Eiholzer, C. Cusano, and J. Mazumder: Proc. Laser Inst. Am., 1984, vol. 44, pp. 159–67.

K. Komvopoulo and K. Nagarathnam: J. Eng. Mater. Technol., 1990, vol. 112, pp. 131–43.

O. Yılmaz, M. Özenbaş, and M.H. Korkut: Mater. Sci. Technol., 2002, vol. 18, pp. 1209–17.

M.H. Korkut, O. Yilmaz, and S. Buytoz: Surf. Coat. Technol., 2002, vol. 157, pp. 5–13.

S. Buytoz, M.M. Yildirim, and H. Eren: Mater. Lett., 2005, vol. 59, pp. 607–14.

S.O. Yılmaz: Surf. Coat. Technol., 2005, vol. 194, pp. 175–83.

A. Lesko and E. Navara: Mater. Charact., 1996, vol. 36, pp. 349–56.

G.V. Raynor and V.G. Rivlin: Phase Equilibria in Iron Ternary Alloys, The Institute of Metals, Bath Press, United Kingdom, 1988, pp. 143–56.

K. Bungardt, E. Kunze, and E. Horn: Arch. Eisenhüttenwes., 1958, vol. 29, pp. 193–201.

M. Chochol, J.F. Elliott and D.M. Kundrat: Metall. Trans. B, 1984, vol. 15B, pp. 663–76.

R.S. Jackson: J. Iron Steel Inst., 1970, vol. 208, pp. 163–70.

Acknowledgment

The authors thank the National Science Council of Taiwan for its financial support (Project No. NSC97-2221-E-005-019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted October 22, 2008.

Rights and permissions

About this article

Cite this article

Lin, CM., Chang, CM., Chen, JH. et al. Microstructural Evolution of Hypoeutectic, Near-Eutectic, and Hypereutectic High-Carbon Cr-Based Hard-Facing Alloys. Metall Mater Trans A 40, 1031–1038 (2009). https://doi.org/10.1007/s11661-009-9784-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-9784-6