Abstract

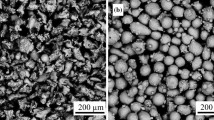

In the present study, attempts have been made to develop SiC dispersed (5 and 20 wt pct) AISI 316L stainless steel matrix composite by direct laser cladding with a high power diode laser. Direct laser cladding has been carried out by melting the powder blends of AISI 316L stainless steel and SiC (5 and 20 wt pct) and, subsequently, depositing it on mild steel (0.15 pct C steel) in a layer by layer fashion to develop a coupon of 100 mm2 × 10 mm dimension. A continuous, defect-free (microcracks and micro- or macroporosities), and homogeneous microstructure is formed, which consists of a dispersion of partially dissolved SiC (leading to formation of very low fraction of Cr3C2 and Fe2Si) in grain-refined austenite. The microhardness of the clad layer increases from 155 VHN to 250 to 340 VHN (for 5 wt pct SiC dispersed) and 450 to 825 VHN (for 20 wt pct SiC dispersed) as compared to 155 VHN of commercially available AISI 316L stainless steel. The corrosion rate in 3.56 wt pct NaCl solution is significantly reduced in 5 wt pct SiC dispersed steel; however, 20 wt pct SiC dispersed steel showed a similar behavior as the commercially available AISI 316L stainless steel. The processing zone for the development of a defect-free microstructure with improved properties has been established.

Similar content being viewed by others

Notes

PHILIPS is a trademark of FEI Company, Hillsboro, OR.

References

C.J. Novak: in Handbook of Stainless Steels, D. Peckner and I.M. Bernstein, eds., McGraw-Hill, New York, NY, 1977, p. 1.

An Introduction to Metal Matrix Composites, T.W. Clyne and P.J. Withers, eds., Cambridge University Press, Cambridge, United Kingdom, 1993.

Laser Material Processing, W.M. Steen, ed., Springer Verlag, New York, NY, 1991, p. 1.

F.T. Cheng, C.T. Kwok, and H.C. Man: Surf. Coat. Technol., 2001, vol. 139, pp. 14–24.

G. Thawari, G. Sundarararjan, and S.V. Joshi: Thin Solid Films, 2003, vol. 423, pp. 41–53.

A. Woldan, J. Kusiński, and E. Tasak: Mater. Chem. Phys., 2003, vol. 81 pp. 507-509.

S. Buytoz and M. Ulutan: Surf. Coat. Technol., 2006, vol. 200 pp. 3698–3734.

Q. Li, G.M. Song, Y.Z. Zhang, T.C. Lei, and W.Z. Chen: Wear, 2003, vol. 254 pp. 222–29.

J. Dutta Majumdar, B. Ramesh Chandra, A.K. Nath, and I. Manna: Phys. Status Solidi (a), 2006, vol. 203, pp. 2260–65.

C. Tassin, F. Laroudie, M. Pons, and L. Lelait: Surf. Coat. Technol., 1996, vol. 80, pp. 207–10.

A.J. Pinkerton and L. Li: Appl. Surf. Sci., 2003, vol. 208, pp. 405–10.

F.G. Arcella and F.H. Froes: J. Met., 2000, vol. 52, pp. 28–30.

D. Srivastava, I.T.H. Chang, and M.H. Loretto: Intermetallics, 2001, vol. 9 pp. 1003–13.

J. Dutta Majumdar, A. Pinkerton, Z. Liu, I. Manna, and L. Li: Appl. Surf. Sci., 2005, vol. 247, pp. 320–27.

J. Dutta Majumdar, A. Pinkerton, Z. Liu, I. Manna, and L. Li: Appl. Surf. Sci., 2005, vol. 247, pp. 373–77.

F. Wang, J. Mei, H. Jiang, and X. Wu: Mater. Sci. Eng., 2007, vols. A445–A446, pp. 461–66.

“Standard Recommended Practice for Conducting Cyclic Potentiodynamic Polarization Measurements for Localized Corrosion,” Annual Book of ASTM Standards, ASTM, Philadelphia, PA, 1985, p. G61.

S. Kalogeropoulou, L. Baud, and N. Eustathopoulos: Acta Metall. Mater., 1995, vol. 43, pp. 907–12.

T. Iseki: in Silicon Carbide—I, Somiya and Y. Inomata, eds., Elsevier Science, New York, NY, 1991, p. 247.

J. Lacaze and B. Sundman: Metall. Trans. A, 1991, vol. 22A, pp. 2211–23.

G. Abbas and U. Ghazanfar: Wear, 2005, vol. 258, pp. 258–64.

Acknowledgments

Financial support from the Department of Science and Technology (Boyscast Scheme, N. Delhi), Council of Scientific and Industrial Research (N. Delhi), and Board of Research on Nuclear Science (Bombay) for the present study is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 28, 2008.

Rights and permissions

About this article

Cite this article

Majumdar, J.D., Li, L. Studies on Direct Laser Cladding of SiC Dispersed AISI 316L Stainless Steel. Metall Mater Trans A 40, 3001–3008 (2009). https://doi.org/10.1007/s11661-009-0018-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0018-8