Abstract

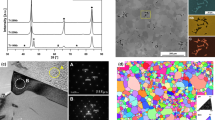

A bulk nanocrystalline 80Ni-15Fe-5Co (wt pct) soft magnetic material was successfully produced via “mechanical alloying-explosive compaction” route. A rapid grain refining was observed during initial 12 hours of milling in high-energy planetary ball mill, followed by a level-off trend. A comparison of crystallite size of 125-hour-milled mechanically-alloyed (MAed) powder (10 nm) and explosively-compacted material (15 nm) showed negligible grain growth during explosive compaction. It has been shown that no phase change was brought about by the explosive compaction of the milled powder, and Ni3Fe remained the predominant phase in both MAed and explosively-compacted material. A possible mechanism of densification of flaky MAed powder during explosive compaction has been proposed, which consisted of the plastic deformation of powder particles into elongated shape followed by joining and folding of elongated particles. This process produced a continuous network of elongated and folded particles in the compact. The bulk nanocrystalline material showed improved magnetic properties, such as high Curie temperature and negligible core loss, making it a promising soft magnetic material for applications involving high temperatures and changing magnetic environment.

Similar content being viewed by others

Notes

JEOL is a trademark of Japan Electron Optics Ltd., Tokyo.

INCONEL is a trademark of Inco Alloys International, Huntington Woods, WV.

References

H. Gleiter: Prog. Mater. Sci., 1989, vol. 33, pp. 223–315

R. Birringer: Mater. Sci. Eng. A, 1989, vol. 117, pp. 33–43

N. Nihara: J. Ceram. Soc. Jpn., 1991, vol. 99 (10), pp. 974–82

C. Kuhourt, L. Schultz: J. Appl. Phys., 1992, vol. 71 (4), pp. 1896–1900

H. Gleiter: Acta Mater., 2000, vol. 48, pp. 1–29

G. Herzer: J. Magn. Magn. Mater., 2005, vol. 294, pp. 99–106

Y. Yoshizawa, S. Oguma, K. Yamauchi: J. Appl. Phys., 1988, vol. 64, pp. 6044–46

G. Herzer: IEEE Trans. Magn., 1990, vol. 26 (5), pp. 1397–402

G. Herzer: J. Magn. Magn. Mater., 1992, vol. 112, pp. 258–62

Y. Yoshizawa: J. Metast. Nanocryst. Mater., 1999, vol. 1, pp. 51–62

G. Herzer: IEEE Trans. Magn., 1989, vol. 25 (5), pp. 3327–29

Y. Yoshizawa: Scripta Mater., 2001, vol. 44, pp. 1321–25

H.J. Fecht, E. Hellstern, Z. Fu, W.L. Johnson: Metall. Trans. A, 1990, vol. 21A, pp. 2333–37

N.E. Fenineche, R. Hamzaoui, O. El Kedim: Mater. Lett., 2003, vol. 57, pp. 4165–69

C. Kuhrt, L. Schultz: J. Appl. Phys., 1993, vol. 73 (10), pp. 6588–90

C.N. Chinnasamy, A. Narayanasamy, N. Ponpandian, K. Chattopadhyay, M. Saravanakumar: Mater. Sci. Eng. A, 2001, vols. 304–306, pp. 408–12

I. Chicinas, O. Geoffroy, O. Isnard, V. Pop: J. Magn. Magn. Mater., 2005, vols. 290–291, pp. 1531–34

G. Gonzales, D. Ibarra, J. Ochoa, R. Villalba, A. Sagarzazu: J. Alloy Compd., 2007, vols. 434–435, pp. 437–41

I. Chicinas, O. Geoffroy, O. Isnard, V. Pop: J. Magn. Magn. Mater., 2007, vol. 310, pp. 2474–76

C. Kuhrt: J. Magn. Magn. Mater., 1996, vols. 157–158, pp. 235–36

H.R.M. Hosseini, A. Bahrami: Mater. Sci. Eng. B, 2005, vol. 123, pp. 74–79

W. Lu, L. Yang, B. Yan, W. Huang, B. Lu: J. Alloy Compd., 2006, vol. 413, pp. 85–89

J. Ding, Y. Li, L.F. Chen, C.R. Deng, Y. Shi, Y.S. Chow, T.B. Gang: J. Alloy Compd., 2001, vol. 314, pp. 262–67

Y. Shen, H.H. Hng, J.T. Oh: J. Alloy Compd., 2004, vol. 379, pp. 266–71

O. Isnard, V. Pop, I. Chicinas: J. Magn. Magn. Mater., 2005, vols. 290–291, pp. 1535–38

W.H. Gourdin: Prog. Mater. Sci., 1986, vol. 30, pp. 39–80

K.I. Kondo, H. Hirai, H. Oda: Jpn. J. Appl. Phys., 1994, vol. 33, pp. 2079–86

C.P. Dogan, J.C. Rawers, R.D. Govier, G. Korth: Nanostr. Mater., 1994, vol. 4 (6), pp. 631–44

S.C. Glade, N.N. Thadani: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 2565–69

G.E. Korth, R.L. Williamson: Metall. Mater. Trans. A, 1995, vol. 26A, pp. 2571–78

J.C. Rawers, G. Korth: Nanostr. Mater., 1996, vol. 7 (1–2), pp. 25–45

C. Suryanarayana, F.H. Froes, G.E. Korth: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 293–302

J.R. Groza: in Non-Equilibrium Processing of Materials, C. Suryanarayana, ed., Pergamon, New York, NY, 1999, ch. 13, p. 368

R.A. Varin, L. Zbroniec, T. Czujko, Y.K. Song: Mater. Sci. Eng. A, 2001, vol. A300, pp. 1–11

T.P. Raming, W.E. Vanzyl, E.P. Carton, H. Verweiz: Ceram. Int., 2004, vol. 30, pp. 629–34

B. Gehrmann: J. Magn. Magn. Mater., 2005, vols. 290–291, pp. 1419–22

H. Gavrila, V. Ionita: J. Optoelec. Adv. Mater., 2002, vol. 4 (2), pp. 173–92

H.P. Klug, L.E. Alexander: X-ray Diffraction Procedures for Polycrystalline and Amorphous Materials, John Wiley and Sons, New York, NY, 1974, pp. 618–708

W. Herrmann: J. Appl. Phys., 1969, vol. 40, p. 2490

M.A. Meyers, S.L. Wang: Acta Metall., 1988, vol. 36, pp. 925–36

M.A. Meyers: Dynamic Behavior of Materials, John Wiley and Sons, Inc., New York, NY, 1994, pp. 124–51

H.L. Coker, M.A. Meyers, J.F. Wessels: J. Mater. Sci., 1991, vol. 26, pp. 1277–86

R.R. Pruemmer, T.B. Bhat, K. Sivakumar, K. Hokamoto: Explosive Compaction of Powders and Composites, Science Publishers, Enfield, NH, 2006, pp. 20–23

I. Chicinas, V. Pop, O. Isnard: J. Magn. Magn. Mater., 2002, vols. 242–245, pp. 885–87

I. Chicinas, V. Pop, O. Isnard, J.M.L. Breton, J. Juraszek: J. Alloy Compd., 2003, vol. 352, pp. 34–40

E. Jartych, J.K. Zurawicz, D. Oleszak, M. Pekala: J. Magn. Magn. Mater., 2000, vol. 208, pp. 221–30

H.N. Frase, R.D. Shull, L.B. Hong, T.A. Stephens, Z.Q. Gao, B. Fultz: Nanostr. Mater., 1999, vol. 11 (8), pp. 987–93

Acknowledgments

The authors acknowledge the support extended by the Director, Terminal Ballistic Research Laboratory (Chandigarh, India) for conducting explosive-compaction tests. We also extend our sincere thanks to M/S Union Miniere, Belgium, for providing Co powder for the present work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 16, 2008.

Rights and permissions

About this article

Cite this article

Vajpai, S., Dube, R. & Tewari, A. Studies on the Mechanical Alloying of Ni-Fe-Co Powders and Its Explosive Compaction. Metall Mater Trans A 39, 2725–2735 (2008). https://doi.org/10.1007/s11661-008-9617-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9617-z