Abstract

The parametric dependencies of threshold stress for superplastic flow were characterized over a wide range of temperatures using a fine-grained magnesium alloy with various grain sizes. The threshold stress was proportional to the reciprocal of the square root of the grain size at 473 K, whereas it was independent of the grain size at 598 K. The threshold stress decreased with increasing deformation temperature more quickly than the shear modulus did. It was suggested that the temperature dependence of the threshold stress is associated with the interaction between the solute atoms and dislocations. The origin of the threshold stress probably resulted from the dislocations breaking away from the solute atmospheres formed in the grain boundaries and in the lattice at low temperatures and at high temperatures, respectively.

Similar content being viewed by others

References

J. Pilling, N. Ridley: Superplasticity in Crystalline Solids, The Institute of Metals, London, 1989, pp. 65–101

T.G. Nieh, J. Wadsworth, O.D. Sherby: Superplasticity in Metals and Ceramics, Cambridge University Press, Cambridge, United Kingdom, 1997, pp. 32–57

O.D. Sherby, E.M. Taleff: Mater. Sci. Eng., 2002, vol. A322, pp. 89–99

J. Fiala, J. Novotný, J. Čadek: Mater. Sci. Eng., 1983, vol. 60, pp. 195–206

R.G. Peters: Scripta Metall., 1983, vol. 17, pp. 587–91

A.H. King: Scripta Metall. Mater., 1994, vol. 31, pp. 1493–94

W.J. Kim, D.W. Kum: Mater. Trans. JIM, 1999, vol. 40, pp. 760–64

P. Málek, M. Cieslar: Mater. Sci. Eng., 1997, vols. A234–A236, pp. 782–85

F.A. Mohamed: J. Mater. Sci., 1983, vol. 18, pp. 582–92

L. Kloc, J. Fiala, J. Čadec: Mater. Sci. Eng., 1990, vol. A130, pp. 165–72

R.S. Mishra, T.R. Bieler, A.K. Mukherjee: Acta Mater., 1995, vol. 43, pp. 877–91

H. Hosokawa, K. Higashi: Metall. Mater. Trans. A, 2006, vol. 37A, pp. 2947–53

G.S. Murty, M.J. Koczak: Mater. Sci. Eng., 1987, vol. 96, pp. 117–24

G.S. Murty, M.J. Koczak: Mater. Sci. Eng., 1988, vol. 100, pp. 37–43

P.K. Chaudhury, V. Sivaramakrishnan, F.A. Mohamed: Metall. Trans. A, 1988, vol. 19A, pp. 2741–52

P.K. Chaudhury, K. Park, F.A. Mohamed: Metall. Mater. Trans. A, 1994, vol. 25A, pp. 2391–2401

Y. Li, T.G. Langdon: Acta Mater., 1997, vol. 45, pp. 4797–4806

Y. Li, T.G. Langdon: Acta Mater., 1998, vol. 46, pp. 1143–55

Y. Li, T.G. Langdon: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 315–24

W.J. Kim: Mater. Sci. Eng., 2000, vol. A277, pp. 134–42

B.Q. Han, T.G. Langdon: Mater. Sci. Eng., 2002, vol. A322, pp. 73–78

E. Sato, M. Valsan, K. Kuribayashi, P. Rodriguez: Mater. Trans., JIM, 1999, vol. 40, pp. 754–59

H. Watanabe, T. Mukai, K. Ishikawa, M. Mabuchi, K. Higashi: Mater. Sci. Eng., 2001, vol. A307, pp. 119–28

H. Watanabe, T. Mukai, M. Mabuchi, K. Higashi: Scripta Mater., 1999, vol. 41, pp. 209–13

ASM Handbook, vol. 2, ASM INTERNATIONAL, Materials Park, OH, 1990, p. 516

O.D. Sherby, J. Wadsworth: Progr. Mater. Sci., 1989, vol. 33, pp. 169–221

G. Rai, N.J. Grant: Metall. Trans. A, 1975, vol. 6A, pp. 385–90

T.G. Langdon: Metall. Trans. A, 1982, vol. 13A, pp. 689–701

K. Higashi, M. Mabuchi, T.G. Langdon: ISIJ Int., 1996, vol. 36, pp. 1423–38

A-U. Karim and W.A. Backofen: Mater. Sci. Eng., 1968–69, vol. 3, pp. 306–07

G.S. Murty: Scripta Mater., 1972, vol. 6, pp. 663–66

M. Mabuchi, T. Asahina, H. Iwasaki, K. Higashi: Mater. Sci. Technol., 1997, vol. 13, pp. 825–31

H. Watanabe, T. Mukai, K. Higashi: Scripta Mater., 1999, vol. 40, pp. 477–84

S. Tandon, G.S. Murty: Mater. Trans. JIM, 1993, vol. 34, pp. 319–24

H.J. Frost, M.F. Ashby: Deformation-Mechanism Maps, Pergamon Press, Oxford, United Kingdom, 1982, pp. 43–46

R.Z. Valiev, O.A. Kaibyshev: Phys. Status Solidi A, 1997, vol. 44, pp. 65–76

M.F. Ashby: Surf. Sci., 1972, vol. 31, pp. 498–542

D. McLean: Philos. Mag., 1971, vol. 23, pp. 467–72

O.D. Sherby, J. Wadsworth: Deformation Processing and Structure, ASM, Metals Park, OH, 1982, pp. 355–88

O.A. Ruano, O.D. Sherby: Mater. Sci. Eng., 1982, vol. 56, pp. 167–75

H. Watanabe, T. Mukai, M. Kohzu, S. Tanabe, K. Higashi: Acta Mater., 1999, vol. 47, pp. 3753–58

H. Watanabe, T. Mukai, M. Mabuchi, K. Higashi: Acta Mater., 2001, vol. 49, pp. 2027–37

H. Watanabe: Doctoral Thesis, Osaka Prefecture University, Sakai, Osaka, Japan, 2002, pp. 96–130

H. Watanabe, T. Mukai, K. Higashi: Mater. Trans., 2004, vol. 45, pp. 2497–2502

E. Arzt, M.F. Ashby, R.A. Verrall: Acta Metall., 1983, vol. 31, pp. 1977–89

J. Rösler, R. Joos, E. Arzt: Metall. Trans. A, 1992, vol. 23A, pp. 1521–39

R.W. Lund, W.D. Nix: Acta Metall., 1976, vol. 24, pp. 469–81

L. Kloc, S. Spigarelli, E. Cerri, E. Evangelista, T.G. Langdon: Acta Mater., 1997, vol. 45, pp. 529–40

U.F. Kocks: Philos. Mag., 1966, vol. 13, pp. 541–66

R.S.W. Shewfelt, L.M. Brown: Philos. Mag., 1977, vol. 35, pp. 945–62

E. Arzt, M.F. Ashby: Scripta Metall., 1982, vol. 16, pp. 1285–90

D.J. Srolovitz, M.J. Luton, R. Petkovic-Luton, D.M. Barnett, W.D. Nix: Acta Metall., 1984, vol. 32, pp. 1079–88

E. Arzt, D.S. Wilkinson: Acta Metall., 1986, vol. 34, pp. 1893–98

E. Arzt, J. Rösler: Acta Metall., 1988, vol. 36, pp. 1053–60

J. Rösler, E. Arzt: Acta Metall. Mater., 1990, vol. 38, pp. 671–83

S.E. Broyles, K.R. Anderson, J.R. Groza, J.C. Gibeling: Metall. Mater. Trans. A, 1996, vol. 27A, pp. 1217–27

R. Kaibyshev, O. Sitdikov, A. Goloborodko, T. Sakai: Key Eng. Mater., 2000, vols. 171–174, pp. 355–62

D. Hull, D.J. Bacon: Introduction to Dislocations, 4th ed., Elsevier, Oxford, United Kingdom, 2001, pp. 202–06

J. Friedel: Dislocations, Pergamon Press, Oxford, United Kingdom, 1964, pp. 351–67

D. Kum, W.-J. Kim: Mater. Sci. Forum, 1999, vols. 304–306, pp. 241–48

J.W. Cahn: Acta Metall., 1956, vol. 4, pp. 449–59

O.D. Sherby, P.M. Burke: Progr. Mater. Sci., 1966, vol. 13, pp. 325–90

O.D. Sherby, J. Wadsworth: Mater. Sci. Forum, 1997, vols. 233–234, pp. 125–38

H. Fukuyo, H.C. Tsai, T. Oyama, O.D. Sherby: ISIJ Int., 1991, vol. 31, pp. 76–85

H. Watanabe, T. Mukai, M. Sugioka, K. Ishikawa: Scripta Mater., 2004, vol. 51, pp. 291–95

J.A. del Valle, F. Carreño, O.A. Ruano: Scripta Mater., 2007, vol. 57, pp. 829–32

H. Watanabe, T. Mukai, K. Ishikawa, Y. Okanda, M. Kohzu, K. Higashi: J. Jpn. Inst. Lt. Met. 1999, vol. 49, pp. 401–04

K. Ishikawa, H. Watanabe, T. Mukai: Mater. Lett., 2005, vol. 59, pp. 1511–15

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 8, 2008.

Appendices

Appendix A

Grain growth during superplastic flow caused both by the exposure at high temperatures and by well-documented strain-induced grain growth has a visible effect on the stress-strain curves; because the flow stress during superplastic flow increases with increasing grain size, work hardening occurs as a result of grain growth. In fact, due to the ease of grain growth in several magnesium alloys, a grain-growth effect on the flow stress is suggested to be the origin of threshold stress-like behavior in the low-strain-rate range.[66] The authors, however, assumed that the grain sizes after static annealing before straining remain unchanged during the tensile deformation up to ε = 0.1; for this reason, the effect of grain growth during deformation to ε = 0.1 on the calculated threshold-stress values was neglected throughout that article.

In the present study, the linear-extrapolation method was adopted to calculate the threshold-stress values. Inspection of Figures 5 and 7 revealed that the n = 2 provided a linear extrapolation, even in the low-strain-rate range. If the threshold stress varies with exposure time or strain rate, the data will not provide a linear extrapolation. The linearity over a wide range of strain rates observed in the present study indicates the absence of significant grain growth, even in the low-strain-rate range.

In order to experimentally confirm the grain-size stability of the materials used in the present study, both the strain-hardening behavior and grain-growth behavior in the gage portion were examined under several extreme conditions (the slowest strain rates or the highest temperatures). The arrows in Figures 2 and 4(a) show the deformation conditions examined in Appendix A. The microstructures of the gage portion were observed after plastic deformation to ε ≈ 0.1, at which the flow stress was determined.

True stress-true strain curves up to ε = 0.2 are shown in Figure A1 for (1) the as-extruded alloy deformed at 523 K and 1 × 10−5 s−1, (2) the as-extruded alloy deformed at 623 K and 1 × 10−3 s−1, and (3) the annealed alloy deformed at 473 K and 3 × 10−6 s−1. The change in the average grain size and the distribution of grain sizes before and after deformation (ε ≈ 0.1) evaluated at the same deformation conditions are shown in Figure A2. The extent of strain hardening was slightly higher in the annealed alloy (Figure A1(c)) than in the as-extruded alloy (Figures A1(a) and (b)). This is probably because of the low strain rate imposed on the specimen (3 × 10−6 s−1). In order to compare the extent of strain hardening with conventional superplastic alloys, the true stress-true strain curve obtained in a superplastic Mg-3 mass pct Al-1 mass pct Zn (AZ31) alloy deformed at 623 K and 1 × 10−3 s−1[67] is shown in Figure A1(b). The alloy was processed by extruding a commercial bar; the grain size of the as-extruded AZ31 was 5.1 μm. The extent of strain hardening was obviously smaller in PM ZK61 for both as-extruded (Figures A1(a) and (b)) and annealed (Figure A1(c)) alloys than that in conventional AZ31. This fact indicates that the grains of the present PM ZK61 are stable at high temperatures, compared with conventional magnesium alloys. In fact, as is evident in Figure A2, the distribution of grain sizes before and after deformation was quite similar at all conditions; the grain growth of PM ZK61 was negligibly small, even after the deformation at extreme conditions. The grain sizes of the superplastically deformed specimens were, at most, 1.2 times larger than those of the undeformed specimens. Since the grain sizes differ slightly form the initial ones, the grain-growth effect on threshold stress was neglected in the present study.

True stress-true strain curves up to ε = 0.2 for (a) the as-extruded alloy deformed at 523 K and 1 × 10−5 s−1, (b) the as-extruded alloy deformed at 623 K and 1 × 10−3 s−1, and (c) the annealed alloy deformed at 473 K and 3 × 10−6 s−1. True stress-true strain curve for the as-extruded AZ31 alloy deformed at 623 K and 1 × 10−3 s−1[67] is also shown in (b)

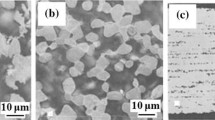

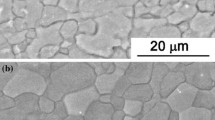

The average grain sizes, d, and distribution of grain size in the PM ZK61 before deformation (upper rows) and after deformation to ε ≈ 0.1 (lower rows): (a) and (b) for the as-extruded alloy deformed at 523 K and 1 × 10−5 s−1; (c) and (d) for the as-extruded alloy deformed at 623 K and 1 × 10−3 s−1; and (e) and (f) for the annealed alloy deformed at 473 K and 3 × 10−6 s−1

Appendix B

It is beneficial to examine the elastic modulus of the present alloy at elevated temperatures. The material used for measurement was ZK60 (Mg-6 mass pct Zn-0.5 mass pct Zr) alloy, assuming similar elastic properties between ZK61 and ZK60. This will be confirmed from the fact that the slight difference in chemical composition does not generally affect the elastic moduli. Hot-extruded ZK60, which was annealed at 723 K for 5 hours before the measurement, was machined into a rectangular specimen. The specimen had a length of 60 mm, a width of 10 mm, and a thickness of 1.5 mm. The annealing treatment led to some sort of bimodal grain mixture, with fine grains 15 μm in size and coarse grains 100 to 500 μm in size. The dynamic shear modulus, G, was measured up to 493 K in every 10 K by employing the method of resonant vibration in cantilever specimen holding.

The measured dynamic shear modulus of ZK60 decreased linearly with increasing temperature up to ∼450 K. This is in contrast to the behavior of AZ91 (Mg-9 mass pct Al-1 mass pct Zn) alloy with a grain size of 70 to 300 μm:[68] the temperature dependence of the measured modulus did not deviate from linearity (dG/dT = −0.0082 GPa K−1), at least up to 623 K. The deviation in ZK60 may be ascribable to the relaxation from the occurrence of GBS,[65] which results from the existence of fine grains 15 μm in size. The dynamic, unrelaxed, shear modulus of ZK60, which was derived by fitting the data from RT to 450 K, was calculated to be G = 18.33 − 0.0090 T, where the units of G and T are GPa and K, respectively. The shear modulus from 473 to 623 K used for the present analysis was estimated by extrapolation.

Rights and permissions

About this article

Cite this article

Watanabe, H., Mukai, T. & Higashi, K. Influence of Temperature and Grain Size on Threshold Stress for Superplastic Flow in a Fine-Grained Magnesium Alloy. Metall Mater Trans A 39, 2351–2362 (2008). https://doi.org/10.1007/s11661-008-9596-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-008-9596-0