Abstract

This study was conducted to compare the hydrogen embrittlement (HE) resistance of austempered 4340 steel with quenched and tempered (Q&T) 4340 steel with an identical yield strength (YS) of 1340 MPa (194 ksi). A baseline comparison showed that the austempered steel with a lower bainite microstructure exhibited higher hardness, tensile strengths, Charpy V-notch (CVN) impact toughness, and ductility at both low 233 K (−40 F) and ambient temperatures, as compared to the Q&T steel with a martensite microstructure. After machining and just prior to testing, subsized CVN specimens and notched bend specimens were immersed in hydrochloric acid-water baths. The HE resistance was higher for the austempered steel than the Q&T steel. No differences in room-temperature CVN energy resulted from hydrogen charging of the austempered and Q&T steels vs their unexposed counterparts. However, in the notched bend specimens, the hydrogen charging caused significant peak load decreases (40 pct) for the Q&T steel, while the austempered steel exhibited only small (6 pct) decreases in peak load. Intergranular (IG) fracture occurred solely in the charged Q&T bend samples, which is further evidence of their embrittlement.

Similar content being viewed by others

References

ASM Handbook, 10th ed., vol. 1, Properties and Selection: Irons, Steels, and High-Performance Alloys, Notch Toughness of Steels, ASM INTERNATIONAL, Materials Park, OH, 1990, p. 748, which cites the original article: R.F. Hehemann, V.J. Luhan, and A.R. Troiano: Trans. ASM, 1957, vol. 49, pp. 409–26

J.H. Chuang, L.W. Tsay, C. Chen: Int. J. Fatigue, 1998, vol. 20 (7), pp. 531–36

L.F. Reynolds, M.P. Hayes: Trans. Inst. Met. Finish., 1987, vol. 65 (2), pp. 50–57

P.Sh. Lantsman, G.G. Vernovskaya, and V.N. Kudryavtsev: translated from Metallovedenie I Termiceskaya Obrabotka Metallov., 1973, No. 5, pp. 73–74

L.J. Habraken and M. Econompoulos: Transformation and Hardenability in Steels, Climax Molybdenum Company of Michigan and University of Michigan Symp., Feb. 27–28, Climax Molybdenum Company of Michigan, Ann Arbor, MI, 1967, pp. 69–107

F.B. Pickering: Transformation and Hardenability in Steels, Climax Molybdenum Company of Michigan and University of Michigan Symp., Feb. 27–28, Climax Molybdenum Company of Michigan, Ann Arbor, MI, 1967, pp. 109–29

ASM Handbook, 10th ed., vol. 1, Properties and Selection: Irons, Steels, and High-Performance Alloys: Notch Toughness of Steels, ASM INTERNATIONAL, Materials Park, OH, 1990, p. 747

D.R. Johnson, W.T. Becker: J. Mater. Eng. Perf., 1993, vol. 2 (2), pp. 255–62

ASM Handbook, 10th ed., vol. 4, Heat Treatment: Austempering of Steel, ASM INTERNATIONAL, Materials Park, OH, 1991, pp. 152–63

H.K.D.H. Bhadeshia: Solid → Solid Phase Transformations in Inorganic Materials, TMS, Warrendale, PA, 2005, vol. 1, pp. 469–84

ASM Handbook, vol. 13A, Corrosion: Fundamentals, Testing and Protection, ASM INTERNATIONAL, Materials Park, OH, 2003, pp. 367–74

ISO 14707:2000E First Edition (2000-18-15): Surface Chemical Analysis—Glow Discharge Optical Emission Spectrometry (GD-OES)—Introduction To Use, ISO 2000, ISO Copyright Office, Geneva, Switzerland, www.iso.ch

ASTM E1019, 2003: Standard Test Methods for Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel and in Iron, Nickel, and Cobalt Alloys, ASTM International, West Conshohocken, PA, www.astm.org

ASTM E18, 2005e1: Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials, ASTM International, West Conshohocken, PA, www.astm.org

ASTM E3, 2001: Standard Practice for Preparation of Metallographic Specimens, ASTM International, West Conshohocken, PA, www.astm.org

ASTM E975, 2003: Standard Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation, ASTM International, West Conshohocken, PA, www.astm.org

ASTM E45, 2005e1: Standard Test Methods for Determining the Inclusion Content of Steel, ASTM International, West Conshohocken, PA, www.astm.org

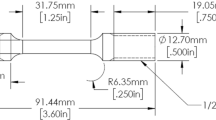

ASTM E8, 2004: Standard Test Methods for Tension Testing of Metallic Materials, ASTM International, West Conshohocken, PA, www.astm.org

ASTM E111, 2004: Standard Test Method for Young’s Modulus, Tangent Modulus, and Chord Modulus, ASTM International, West Conshohocken, PA, www.astm.org

ASTM E646, 2000: Standard Test Method for Tensile Strain-Hardening Exponents (n-Values) of Metallic Sheet Materials, ASTM International, West Conshohocken, PA, www.astm.org

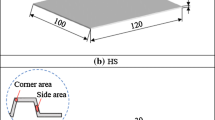

ASTM E23, 2006: Standard Test Methods for Notched Bar Impact Testing of Metallic Materials, ASTM International, West Conshohocken, PA, www.astm.org

ASTM G129, 2000 (2006): Standard Practice for Slow Strain Rate Testing to Evaluate the Susceptibility of Metallic Materials to Environmentally Assisted Cracking, ASTM International, West Conshohocken, PA, www.astm.org

Y. Tomita, K. Okabayashi: Metall. Trans. A, 1986, vol. 17A, pp. 1203–09

ASTM A370, 2006: Standard Test Methods and Definitions for Mechanical Testing of Steel Products, ASTM International, West Conshohocken, PA, www.astm.org

G.E. Dieter: Mechanical Metallurgy, 3rd ed., McGraw-Hill Book Company, New York, NY, 1986, pp. 197–201, 282–83, and 490–93

P.M. Novotny: Adv. Mater. Processes, 2007, vol. 165 (5), pp. 29–31

ASTM E855, 1990: Standard Test Methods for Bend Testing of Metallic Flat Materials for Spring Applications Involving Static Loading, ASTM International, West Conshohocken, PA, 2000, www.astm.org

ASM Handbook: Fractography, 9th ed., ASM INTERNATIONAL, Metals Park, OH, 1987, vol. 12, pp. 12–31

C.J. McMahon Jr.: Eng. Fract. Mech., 2001, vol. 68, pp. 773–88

A.R. Troiano: Trans. ASM, 1960, vol. 52, pp. 54–80

G. Krauss: Steels: Processing, Structure, and Performance, ASM INTERNATIONAL, Materials Park, OH, 2005, pp. 406–10

ASM Handbook: Failure Analysis and Prevention, vol. 11, ASM INTERNATIONAL, Metals Park, OH, 2002, pp. 99–101

M. Wang, E. Akiyama, K. Tsuzaki: Scripta Mater., 2005, vol. 53, pp. 713–18

W.W. Gerberich, T. Livne, X.-F. Chen, M. Kaczorowski: Metall. Trans. A, 1988, vol. 19A, pp. 1319–34

Mechanical Hydrogen Embrittlement Methods for Evaluation and Control of Fasteners, ASTM, West Conshoshocken, PA, 2001, pp. 1–25

Acknowledgments

The authors thank all the test technicians at Stork Climax Research Services (CRS) and Terry Lusk at Applied Process, Inc., for meticulously conducting the experiments. The authors also acknowledge the guidance that Stork CRS metallurgical engineers Rick Gundlach and Art Griebel provided with the hydrogen charging and bend testing procedures, respectively.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 23, 2007.

An erratum to this article can be found at http://dx.doi.org/10.1007/s11661-008-9521-6

Rights and permissions

About this article

Cite this article

Tartaglia, J., Lazzari, K., Hui, G. et al. A Comparison of Mechanical Properties and Hydrogen Embrittlement Resistance of Austempered vs Quenched and Tempered 4340 Steel. Metall Mater Trans A 39, 559–576 (2008). https://doi.org/10.1007/s11661-007-9451-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-007-9451-8