Abstract

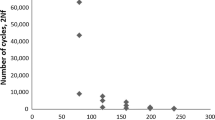

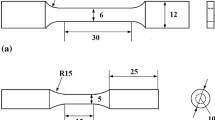

The very high-cycle fatigue behavior of a 319-type cast aluminum alloy was investigated using ultrasonic fatigue instrumentation operating at 20 kHz. An endurance limit was demonstrated in the lifetime regime beyond 107 cycles. Accordingly, the fatigue strength at 108 cycles was determined using the staircase test method. Large pores at or close to the specimen surface or in the specimen interior were responsible for crack initiation in all specimens, and the staircase results were associated with both size and location of the initiating pores through a critical stress intensity factor for fatigue crack growth. Based on the experimental observations, a probabilistic model was developed to establish the relationship between the porosity population and the fatigue strength of the alloy. Good agreement was obtained between the modeling results and experiments.

Similar content being viewed by others

Notes

MatLab is a trademark of The MathWorks Inc., Novi, MI, USA

References

C. Nyahumwa, N.R. Green, J. Campbell: Metall. Mater. Trans. A, 2001, 32A: 349–58

J.M. Boileau, J.E. Allison: Metall. Mater. Trans. A, 2003, 34A:1807–20

J.M. Boileau, J.W. Zindel, J.E. Allison: SAE Technical Paper Series, 1997, 970019

M.J. Caton, J.W. Jones, J.E. Allison: Mater. Sci. Eng. A, 2001, 314:81–85

Y.X. Gao, J.Z. Yi, P.D. Lee, T.C. Lindley: Fatigue Fract. Eng. Mater. Struct., 2004, 27: 559–70

Q.G. Wang: J. Mater. Manufacturing, 2004, 112:396–404

J.Z. Yi, Y.X. Gao, P.D. Lee, T.C. Lindley: Metall. Mater. Trans. B, 2006, 37B: 301–11

M.J. Couper, A.E. Neeson, J.R. Griffiths: Fatigue Fract. Eng. Mater. Struct., 1990, 13:213–27

K. Shiozawa, Y. Tohda, S.-M. Sun: Fatigue Fract. Eng. Mater. Struct., 1997, 20: 237–47

M.J. Caton, J.W. Jones, J.M. Boileau, J.E. Allison: Metall. Mater. Trans. A, 1999, 30A: 3055–68

M.J. Caton, J.W. Jones, H. Mayer, S. Stanzl-Tschegg, J.E. Allison: Metall. Mater. Trans. A, 2003, 34A:33–41

B. Skallerud, T. Iveland, G. Harkegard: Eng. Fract. Mech., 1993, 44:857–74

Y. Murakami: Metal Fatigue: Effect of Small Defects and Nonmetallic Inclusions, Elsevier Science Ltd., Boston, MA, 2002, p. 369

Y.X. Gao, J.Z. Yi, P.D. Lee, T.C. Lindley: Acta Mater., 2004, 52: 5435–49

H. Mayer: Int. Mater. Rev., 1999, 44: 1–34

X. Zhu, A. Shyam, J.W. Jones, H. Mayer, J.V. Lasecki, J.E. Allison: Int. J. Fatigue, 3rd Int. Conf. on Very High Cycle Fatigue (VHCF-3), 2006, 28:1566–71

J.A. Collins: Failure of Materials in Mechanical Design, John Wiley & Sons, New York, NY, 1981, pp. 383–88

C.C. Engler-Pinto, Jr., J.V. Lasecki, R.J. Frisch, Sr., M.A. DeJack, and J.E. Allison: SAE Technical Paper Series, 2005, 2005-01-0802

Y. Murakami, M. Endo: Int. J. Fatigue, 1994, 16:163–82

K. Gall, M.F. Horstemeyer, B.W. Degner, D.L. McDowell, J. Fan: Int. J. Fract., 2001, 108:207–33

J. Cheong: Master’s Thesis, Imperial College, London, United Kingdom, 2002

S.G. Lee, A.M. Gokhale, A. Sreeranganathan: Mater. Sci. Eng. A, 2006, 427:92–98

R.L. Fullman: Trans. AIME, 1953, 197:447–52

E.E. Underwood: Quantitative Stereology, Addison-Wesley, London, 1970, pp. 109–45

J.E. Spowart, B. Maruyama, D.B. Miracle: Mater. Sci. Eng. A, 2001, 307:51–66

Q.G. Wang, D. Apelian, D.A. Lados: J. Light Met., 2001, 1: 73–84

J.Z. Yi, Y.X. Gao, P.D. Lee, H.M. Flower, T.C. Lindley: Metall. Mater. Trans. A, 2003, 34A: 1879–90

H. Mayer, M. Papakyriacou, B. Zettl, S.E. Stanzl-Tschegg: Int. J. Fatigue, 2003, 25:245–56

C.C. Engler-Pinto, Jr., R.J. Frisch, Sr., J.V. Lasecki, and J.E. Allison: SAE Technical Paper Series, 2006, 2006–01–0540

X. Zhu, J.Z. Yi, J.W. Jones, and J.E. Allison: Fatigue 2006—9th Int. Congr. on Fatigue, Atlanta, GA, 2006

J.A. Collins: Failure of Materials in Mechanical Design, John Wiley & Sons, New York, NY, 1981, p. 629

J.-Y. Buffiere, S. Savelli, P.H. Jouneau, E. Maire, R. Fougeres: Mater. Sci. Eng., 2001, A316:115–26

Q.G. Wang, D. Apelian, D.A. Lados: J. Light Met., 2001, 1:85–97

J.C. Ting, V. Frederick, F.V. Lawrence: Fatigue Fract. Eng. Mater. Struct., 1993, 16: 631–47

M.E. Seniw, J.G. Conley, M.E. Fine: Mater. Sci. Eng. A, 2000, 285: 43–48

M.J. Caton, J.W. Jones, and J.E. Allison, in Fatigue Crack Growth Thresholds, Endurance Limits, and Design, ASTM STP 1732, J.C.J. Newman and R.S. Piascik, eds., ASTM, Philadelphia, PA, 2000, pp. 285–303

M.J. Caton, J.W. Jones, J.M. Boileau, J.E. Allison: Metall. Mater. Trans. A, 1999, 30A: 3055–68

A. Shyam, J.E. Allison, J.W. Jones: Acta Mater., 2005, 53: 1499–1509

M.J. Caton: Ph.D. Thesis, University of Michigan, Ann Arbor, MI, 2000

S.E. Stanzl-Tschegg, H.R. Mayer, E.K. Tschegg, A. Beste: Int. J. Fatigue, 1993, 15: 311–16

M.J. Couper, J.R. Griffiths: Fatigue Fract. Eng. Mater. Struct., 1990, 13:615–24

R.W. Hamilton, D. See, S. Butler, P.D. Lee: Mater. Sci. Eng. A, 2003, 343:290–300

Acknowledgments

Financial support provided by the United States National Science Foundation (Grant No. DMR 0211067) and Ford Motor Company is gratefully acknowledged. The authors thank Dr. J. Zindel and L. Godlewski for their assistance with the casting of the materials; Christopher J. Torbet for his technical assistance; and Charles Annis, P.E., for comments on probabilistic modeling.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted: May 31, 2006.

Rights and permissions

About this article

Cite this article

Zhu, X., Yi, J., Jones, J. et al. A Probabilistic Model of Fatigue Strength Controlled by Porosity Population in a 319-Type Cast Aluminum Alloy: Part I. Model Development. Metall Mater Trans A 38, 1111–1122 (2007). https://doi.org/10.1007/s11661-006-9070-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-9070-9