Abstract

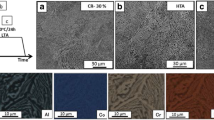

A commercial Al-6 pct Mg-0.3 pct Sc-0.3 pct Mn alloy subjected to equal-channel angular extrusion (ECAE) at 325 °C to a total strain of about 16 resulted in an average grain size of about 1 µm. Superplastic properties and microstructural evolution of the alloy were studied in tension at strain rates ranging from 1.4 × 10−5 to 1.4 s−1 in the temperature interval 250 °C to 500 °C. It was shown that this alloy exhibited superior superplastic properties in the wide temperature range 250 °C to 500 °C at strain rates higher than 10−2 s−1. The highest elongation to failure of 2000 pct was attained at a temperature of 450 °C and an initial strain rate of 5.6 × 10−2 s−1 with the corresponding strain rate sensitivity coefficient of 0.46. An increase in temperature from 250 °C to 500 °C resulted in a shift of the optimal strain rate for superplasticity, at which highest ductility appeared, to higher strain rates. Superior superplastic properties of the commercial Al-Mg-Sc alloy are attributed to high stability of ultrafine grain structure under static annealing and superplastic deformation at T ≤ 450 °C. Two different fracture mechanisms were revealed. At temperatures higher than 300 °C or strain rates less than 10−1 s−1, failure took place in a brittle manner almost without necking, and cavitation played a major role in the failure. In contrast, at low temperatures or high strain rates, fracture occurred in a ductile manner by localized necking. The results suggest that the development of ultrafine-grained structure in the commercial Al-Mg-Sc alloy enables superplastic deformation at high strain rates and low temperatures, making the process of superplastic forming commercially attractive for the fabrication of high-volume components.

Similar content being viewed by others

References

YA. Filatov, V.I. Yelagin, and V.V. Zakharov: Mater. Sci. Eng., 2000, vol. 280A, pp. 97–101.

R.R. Sawtell and C.L. Jensen: Metall. Trans. A, 1990, vol. 21A, pp. 421–30.

Z. Horita, M. Furukawa, M. Nemoto, A.J. Barnes, and T.G. Langdon: Acta Mater., 2000, vol. 48, pp. 3633–40.

M. Furukawa, A. Utsunomiya, K. Matsubara, Z. Horita, and T.G. Langdon: Acta Mater., 2001, vol. 49, pp. 3829–38.

S. Lee, A Utsunomiya, H. Akamatsu, K. Naishi, M. Furukawa, Z. Horita, and T.G. Langdon: Acta Mater., 2002, vol. 50, pp. 553–64.

S. Komura, Z. Horita, M. Furukawa, M. Nemoto, and T.G. Langdon: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 707–16.

T.G. Nieh, L.M. Hsiung, J. Wadsworth, and R. Kaibyshev: Acta Mater., 1998, vol. 46, pp. 2789–00.

T.R. McNelley, E.-W. Lee, and M.E. Mills: Metall. Trans. A, 1986, vol. 17A, pp. 1035–41.

S.J. Hales and T.R. McNelley: Acta Metall., 1988, vol. 36, pp. 1229–39.

S.J. Hales, T.R. McNelley, and H.J. McQueen: Metall. Trans., 1991, vol. 22A, pp. 1037–47.

E.W. Lee and T.R. McNelley: Mater. Sci. Eng., 1987, vol. 93, pp. 45–55.

Z. Horita, M. Furukawa, M. Nemoto, and T.G. Langdon: Mater. Sci. Technol., 2000, vol. 16, pp. 1239–45.

J. Pilling and N. Ridley: Superplasticity in Crystaline Solids, The Institute of Metals, London, 1989, p. 214.

O.A. Kaibyshev: Superplasticity of Alloys, Intermetallides, and Ceramics, Springer-Verlag, Berlin, 1992, p. 316.

T.G. Nieh, J. Wadsworth, and O.D. Sherby: Superplasticity in Metals and Ceramics, Cambridge University Press, New York, NY, 1996, p. 210.

R. Kaibyshev, F. Musin, D.R. Lesuer, and T.G. Nieh: Mater. Sci. Eng., 2003, vol. A342, pp. 169–77.

J.W. Edington, K.N. Melton, and C.P. Cutler: Progr. Mater. Sci., 1976, vol. 21, pp. 161–68.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Musin, F., Kaibyshev, R., Motohashi, Y. et al. Superplastic behavior and microstructure evolution in a commercial Al-Mg-Sc alloy subjected to intense plastic straining. Metall Mater Trans A 35, 2383–2392 (2004). https://doi.org/10.1007/s11661-006-0218-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-0218-4