Abstract

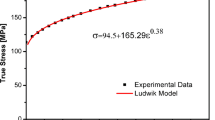

Aluminum-based particulate-reinforced metal matrix composites (PMMCs) frequently have a heterogeneous distribution of reinforcement particles whether produced by a powder or liquid processing route. The applicability of X-ray microtomography (XMT) for the characterization of this heterogeneity, and its influence on final properties, was investigated for the case of a powder blended and extruded AA2124 matrix with Ni particulate. Three-dimensional image analysis techniques were used to quantify the embedded Ni particle size distribution and the extent and texture of clusters formed. The XMT data were exploited as a rapid method to generate a microstructurally accurate and robust three-dimensional mesh for input for finite-element modeling. Simulation of the elastoplastic response of the material showed excellent correlation with experimental results.

Similar content being viewed by others

References

J. Boselli, P.D. Pitcher, P.J. Gregson, and I. Sinclair: J. Microsc., 1999, vol. 195 (2), pp. 104–12.

J. Boselli, P.D. Pitcher, P.J. Gregson, and I. Sinclair: Mater. Sci. Eng., A, 2001, vol. 300 (1–2), pp. 113–24.

R.C. Atwood, J.R. Jones, P.D. Lee, and L.L. Hench: Scripta Mater., 2004, vol. 51 (11), pp. 1029–33.

S. Youssef, E. Maire, and R. Gaertner: Acta Mater., 2005, vol. 53 (3), pp. 719–30.

N.C.W. Kuijpers, J. Tirel, D.N. Hanlon, and S. van der Zwaag: Mater. Characterization, 2002, vol. 48 (5), pp. 379–92.

J.Z. Yi, Y.X. Gao, P.D. Lee, and T.C. Lindley: Mater. Sci. Eng., A, 2004, vol. 386, pp. 394–407.

J.Z. Yi, Y.X. Gao, P.D. Lee, H.M. Flower, and T.C. Lindley: Metall. Trans. A, 2003, vol. 34A, pp. 1879–91.

M. Li, S. Ghosh, O. Richmond, H. Weiland, and T.N. Rouns: Mater. Sci. Eng., A, 1999, vol. 266 (1–2), pp. 221–40.

M. Li, S. Ghosh, O. Richmond, H. Weiland, and T.N. Rouns: Mater. Sci. Eng., A, 1999, vol. 265 (1–2), pp. 153–73.

S. Ghosh, Z. Nowak, and K. Lee: Acta Mater., 1997, vol. 45 (6), pp. 2215–34.

P. Raghavan, S. Li, and S. Ghosh: Fin. Elem. Anal. Des., 2004, vol. 40 (12), pp. 1619–40.

C. Kadar, E. Maire, A. Borbely, G. Peix, J. Lendvai, and Z. Rajkovits: Mater. Sci. Eng., A, 2004, vols. 387–389, pp. 321–25.

J.S. Chen and S. Mehraeen: Proc. IMECE, Anaheim, CA, Nov. 13–19, 2004.

J. Alkemper and P.W. Voorhees: Acta Mater., 2001, vol. 49 (5), pp. 897–902.

H. Singh and A.M. Gokhale: Mater. Characterization, 2005, vol. 54 (1), pp. 21–29.

S. Ghosh, M. Li, S. Moorthy, and K. Lee: Mater. Sci. Eng., A, 1998, vol. 249 (1–2), pp. 62–70.

M.V. Kral and G. Spanos: Scripta Mater., 1997, vol. 36 (8), pp. 875–82.

Y.X. Gao, J.Z. Yi, P.D. Lee, and T.C. Lindley: Acta Mater., 2004, vol. 52 (19), pp. 5435–49.

N. Chawla, V.V. Ganesh, and B. Wunsch: Scripta Mater., 2004, vol. 51 (2), pp. 161–65.

J.E. Spowart, H.M. Mullens, and B.T. Puchala: JOM, 2003, vol. 10, pp. 35–37.

R.H. Bossi, J.L. Cline, and G.E. Georgeson: Report No. WL-TR-91-4102, Wright Laboratory, 1992.

J.Y. Buffiere, E. Maire, P. Cloetens, G. Lormand, and R. Fourgeres: Acta Mater., 1999, vol. 47 (5), pp. 1613–25.

A. Elmoutaouakkil, G. Fuchs, P. Bergounhon, R. Peres, and F. Peyrin: J. Phys. D: Appl. Phys., 2003, vol. 36 (10A), pp. A37-A43.

M. Gonzalez, G. Dominguez, and C. Bathias: ASTM J. Compos. Technol. Res., 2000, vol. 22 (1), pp. 45–48.

A. Guvenilir and S.R. Stock: Fatigue Fract. Eng. Mater. Struct., 1998, vol. 21 (4), pp. 439–50.

E. Maire, L. Babout, J.Y. Buffiere, and R. Fougeres: Mater. Sci. Eng., A, 2001, vols. 319–321, pp. 216–19.

L. Salvo, P. Cloetens, E. Maire, S. Zabler, J.J. Blandin, J.Y. Buffiere, W. Ludwig, E. Boller, D. Bellet, and C. Josserond: Nucl. Instrum. Methods Phys. Res., Sect. B, 2003, vol. 200, pp. 273–86.

L. Babout, E. Maire, and R. Fougeres: Acta Mater., 2004, vol. 52 (8), pp. 2475–87.

L. Babout, P.M. Mummery, T.J. Marrow, A. Tzelepi, and P.J. Withers: Carbon, 2005, 43 (4), pp. 765–74.

H. Bart-Smith, A.-F. Bastawros, D.R. Mumm, A.G. Evans, D.J. Sypeck, and H.N.G. Wadley: Acta Mater., 1998, vol. 46 (10), pp. 3583–92.

J.P. Weiler, J.T. Wood, R.J. Klassen, E. Maire, R. Berkmortel, and G. Wang: Mater. Sci. Eng., A, 2005, vol. 395 (1–2), pp. 315–22.

O.B. Olurin, M. Arnold, C. Korner, and R.F. Singer: Mater. Sci. Eng., A, 2002, vol. 328 (1–2), pp. 334–43.

T.G. Nieh, K. Higashi, and J. Wadsworth: Mater. Sci. Eng., A, 2000, vol. 283 (1–2), pp. 105–10.

R.W. Hamilton, M.F. Forster, R.J. Dashwood, and P.D. Lee: Scripta Mater., 2002, vol. 46 (1), pp. 25–29.

I.G. Watson, M.F. Forster, P.D. Lee, R.J. Dashwood, R.W. Hamilton, and A. Chirazi, Comp. A., 2005, vol. 36, pp. 1177–87.

E.J. Garboczi: Cem. Concr. Res., 2002, vol. 32 (10), pp. 1621–38.

P. Kenesei, A. Borbely, and H. Biermann: Mater. Sci. Eng., A, 2004, vols. 387–389, pp. 852–56.

J.E. Hatch: Aluminium Properties and Physical Metallurgy, 6th ed., ASM, Metals Park, OH, 1984, pp. 235–36.

E.J. Minay, H.B. McShane, and R.D. Rawlings: Intermetallics, 2004, vol. 12 (1), pp. 75–84.

A.C. Kak and M. Slaney: Principles of Computerized Tomographic Imaging, SIAM, New York, NY, 2001, pp. 100–08.

L.A. Feldkamp, L.C. Davis, and J.W. Kress: J. Opt. Soc. Am. A, 1984, vol. 1, pp. 612–19.

H.K. Hong, C.S. Liu, Y.P. Shiao, and B.C. Shih: J. Eng. Mater. Technol. (Trans. ASME), 2002, vol. 124 (3), pp. 314–21.

L. Zhonghua, S. Schmauder, A. Wanner, and M. Dong: Scripta Metall. Mater., 1995, vol. 33 (8), pp. 1289–94.

E.J. Garboczi and A.R. Day: J. Mech. Phys. Solids, 1995, vol. 43 (13), pp. 49–62.

W.E. Lorensen and H.E. Cline: Comp. Graphs, 1987, vol. 213 (1), pp. 63–69.

P.J. Withers: University of Manchester, Manchester, UK, Personal communication, Application of X-ray tomography to study fracture and crack growth workshop, Cambridge, 2005.

E.E. Underwood: in Quantitative Microscopy, DeHoff and Rhines, McGraw-Hill Book Company, New York, NY, 1968, pp. 149–200

X.D. Ding, Z.H. Jiang, J. Sun, J.S. Lian, and L. Xiao: Comp. Sci. Technol., 2002, 62 (6), pp. 841–50.

E. Soppa, S. Schmauder, G. Fischer, J. Brollo, and U. Weber: Comput. Mater. Sci, 2003, vol. 28 (3–4), pp. 574–86.

L.Z. Sun, J.W. Ju, and H.T. Liu: Mech. Mater., 2003, vol. 35 (3–6), pp. 559–69.

J. Segurado and J. LLorca: Acta Mater., vol. 53, pp. 4931–42.

Author information

Authors and Affiliations

Additional information

This article is based on a presentation made in the symposium “Computational Aspects of Mechanical Properties of Materials,” which occurred at the 2005 TMS Annual Meeting, February 13–17, 2005, in San Francisco, CA, under the auspices of the MPMD-Computational Materials Science & Engineering (Jt. ASM-MSCTS) Committee.

Rights and permissions

About this article

Cite this article

Watson, I.G., Lee, P.D., Dashwood, R.J. et al. Simulation of the mechanical properties of an aluminum matrix composite using X-ray microtomography. Metall Mater Trans A 37, 551–558 (2006). https://doi.org/10.1007/s11661-006-0027-9

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-0027-9