Abstract

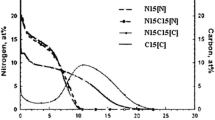

Gas carburizing of high-alloyed stainless steels increases surface hardness, as well as the overall mechanical characteristics of the surface. The growth of chromium-rich carbides during carbon transfer into the steel causes precipitation hardening in the surface, but decreases the chromium content in solid solution. In order to maintain a good corrosion resistance in the carburized layer, the stainless steel composition and the carburizing process need to be optimized. To limit the experimental work, a methodology using software for modeling the thermodynamic and kinetic properties in order to simulate carbon diffusion and phase transformations during gas carburizing is presented. Thermodynamic calculations are initially used to find the optimum parameters (T, carbon wt pct, etc.) in order to maintain the highest Cr and Mo contents in the austenitic solid solution. In a second step, kinetic calculations using the diffusion-controlled transformations (DICTRA) software are used to predict how the amount of the different phases varies and how the carbon profile in the steel changes as a function of time during the process. Experimental carbon profiles were determined using a wavelength-dispersive spectrometer for electron-probe microanalysis (WDS-EPMA), while carbide compositions were measured by energy-dispersive spectroscopy_X (EDS_X) analyses. A good agreement between calculated and experimental values was observed for the Fe-13Cr-5Co-3Ni-2Mo-0.07C and the Fe-12Cr-2Ni-2Mo-0.12C (wt pct) martensitic stainless steels at 955 °C and 980 °C.

Similar content being viewed by others

References

M. Hillert: in Computer Modeling of Phase Diagrams, L.H. Bennett, ed., TMS-AIME, Warrendale, PA, 1986, pp. 1–17.

A. Borgenstam, A. Engström, L. Höglund, and J. Ågren: J. Phase Equilibria, 2000, vol. 21, pp. 269–80.

N. Saunders and A.P. Miodownik: CALPHAD, Calculation of Phases Diagrams, A Comprehensive Guide, Pergamon Series, Pergamon Press, New York, NY, 1998.

L. Kaufman and H. Bernstein: Computer Calculations of Phase Diagrams, Academic Press, New York, 1970; also CALPHAD J.

A. Engström, L. Höglund, and J. Ågren: Mater. Sci. Forum, 1994, vols. 163–165, pp. 725–30.

J. Ågren: Iron Steel Inst. Jpn. Int., 1994, vol. 32, pp. 291–96.

J.O. Andersson, L. Höglund, B. Jönsson, and J. Ågren: Fundamentals and Applications of Ternary Diffusion, G.R. Purdy, ed., Pergamon Press, New York, NY, 1990, pp. 153–63.

J. Ågren: J. Phys. Chem. Solids, 1982, vol. 43, pp. 385–91.

T. Helander and J. Ågren: Metall. Trans. A, 1997, vol. 28A, pp. 303–08.

Z.I. Liu, L. Höglund, B. Jönsson, and J. Ågren: Metall. Trans. A, 1991, vol. 22A, pp. 1745–52.

J.S. Kirkaldy and D.J. Young: Diffusion in the Condensed State, The Institute of Metals, London, 1987, pp. 150–70.

J. Ågren: Current Opinion in Solid State & Materials Science, 1996, vol. 1, pp. 355–60.

B. Sundman: Scand. J. Metall., 1991, vol. 20, pp. 79–85.

B. Jansson, B. Jönsson, Bo. Sundman, and J. Ågren: Thermochimica Acta, 1993, vol. 214, pp. 93–96.

TCFE2000 Solution Database, provided by Thermo-Calc AB, Royal Institute of Technology, Stockholm, 2000.

Bo. Sundman, and J. Ågren: J. Phys. Chem. Solids, 1981, vol. 42, pp. 297–301.

P. Franke and G. Inden: Z. Metallkd., 1997, vol. 88, pp. 795–99.

A. Engström, J.E. Morral, and J. Ågren: Acta Mater., 1997, vol. 45, pp. 1189–99.

A. Engström, L. Höglund, and J. Ågren: Metall. Trans. A, 1994, vol. 25A, pp. 1127–34.

L. Onsager: Phys. Rev., 1931, vol. 37, pp. 405–25; vol. 38, pp. 2265–79.

J.O. Andersson and J. ågren: J. Appl. Phys., 1992, vol. 72, pp. 1350–55.

MOB2 Mobility Database, A. Engström, ed., Thermo-Calc AB, Royal Institute of Technology, Stockholm, 1998; also info@Thermo-Calc.se

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Turpin, T., Dulcy, J. & Gantois, M. Carbon diffusion and phase transformations during gas carburizing of high-alloyed stainless steels: Experimental study and theoretical modeling. Metall Mater Trans A 36, 2751–2760 (2005). https://doi.org/10.1007/s11661-005-0271-4

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-005-0271-4