Abstract

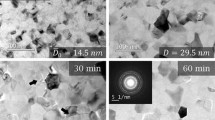

Grain growth of nanocrystalline Ni powders with an average grain size of ∼22 nm prepared by cryogenic mechanical milling (or cryomilling) was investigated by using X-ray diffraction (XRD) and transmission electron microscopy (TEM). A dispersion of NiO and Ni3N particles with a size less than 5 nm was formed in the cryomilled powders. The Ni3N particles decomposed at 773 K. It was found that at 0.56 homologous temperature (T/T M ), Ni grains were retained at ∼150 nm even after long annealing times (e.g., 4 hours). For 0.45 to 0.62 T/T M , the time exponent n deduced from D 1/n−D 1/n0 =kt was 0.16 to 0.32, tending toward 0.5 as T/T M increased. The activation energy for grain growth in the Ni sample was determined to be 113 kJ/mol, which is close to the activation energy for grain boundary self-diffusion in polycrystalline Ni. The observed high grain size stability was attributed primarily to a grain boundary pinning mechanism arising from the NiO particles as well as impurity segregation.

Similar content being viewed by others

References

H. Gleiter: Acta Mater., 2000, vol. 48, pp. 1–29.

J. Verhoeven: Fundamentals of Physical Metallurgy, John Wiley & Sons, New York, NY, 1975, p. 204.

J. Eckert, J.C. Holzer, and W.L. Johnson: J. Appl. Phys., 1993, vol. 73, pp. 131–41.

R.J. Perez, H.G. Jiang, C.P. Dogan, and E.J. Lavernia: Metall. Mater. Trans. A, 1998, vol. 29A, pp. 2469–75.

K. Boylan, D. Ostrander, U. Erb, G. Palumbo, and K.T. Aust: Scripta Metall. Mater., 1991, vol. 25, pp. 2711–16.

D.G. Morris and M.A. Morris: Acta Metall. Mater., 1991, vol. 39, pp. 1763–70.

T.R. Malow and C.C. Koch: Acta Mater., 1997, vol. 45, pp. 2177–86.

P. Knauth, A. Charai, and P. Gas: Scripta Metall. Mater., 1993, vol. 28, pp. 325–30.

H.J. Höfler and R.S. Averback: Scripta Metall. Mater., 1990, vol. 24, pp. 2401–06.

C. Bansal, Z. Gao, and B. Fultz: Nanostr. Mater., 1995, vol. 5, pp. 327–36.

B. Huang, R.J. Perez, and E.J. Lavernia: Mater. Sci. Eng. A, 1998, vol. A255, pp. 124–32.

K.H. Chung, J. Lee, R. Rodriguez, and E.J. Lavernia: Metall. Mater. Trans. A, 2001, vol. 32A, in press.

F. Zhou, J. Lee, and E.J. Lavernia: Scripta Mater., 2001, vol. 44, pp. 2013–17.

M.J. Luton, C.S. Jayanth, M.M. Disco, S. Matras, and J. Vallone: in Multicomponent Ultrafine Microstructures, L.E. McCandlish, B.H. Kear, D.E. Polk, and R.W. Siegel, eds. Materials Research Society, Pittsburgh, PA, 1989, pp. 79–86.

M. Kambara, K. Uenishi, and K.F. Kobayashi: J. Mater. Sci., 2000, vol. 35, pp. 2897–2905.

C. Suryanarayana and M. Norton: X-ray Diffraction: A Practical Approach, Plenum Press, New York, NY, 1998, p. 207.

J. Eckert, J.C. Holzer, C.E. Krill III, and W.L. Johnson: J. Mater. Res., 1992, vol. 7, pp. 1751–61.

H. Fecht, E. Hellstern, Z. Fu, and W.L. Johnson: Metall. Trans. A, 1990, vol. 21A, pp. 2333–37.

C.C. Koch: Nanostr. Mater., 1997, vol. 9, pp. 13–22.

F. Zhou, K.H. Chung, and E.J. Lavernia: in Powder Metallurgy and Particulate Materials for Industrial Applications, A. Alman and J. Newkirk, eds., TMS, Warrendale, PA, 2000, pp. 167–77.

P.S. Gilman and J.S. Benjamin: Ann. Rev. Mater. Sci., 1983, vol. 13, pp. 279–300.

M.L. Lau, H.G. Jiang, W. Nuchter, and E.J. Lavernia: Phys. Status Solidi (A), 1998, vol. 166, pp. 257–68.

B. Huang, J. Vallone, and M.J. Luton: Nanostr. Mater., 1995, vol. 5, pp. 631–42.

C. Smithells: Metals Reference Book, 5th ed., Butterworth and Co., London, 1976, p. 205.

K.Y. Wang, T.D. Shen, H.G. Jiang, M.X. Quan, and W.D. Wei: Mater. Sci. Eng. A, 1994, vol. 179, pp. 215–19.

W. McClune: Powder Diffraction File Alphabetical Index, Inorganic Phases, JCPDS International Center for Diffraction Data, Swarthmore, PA, 1988.

T.B. Massalski: Binary Alloy Phase Diagrams, 2nd ed., ASM INTERNATIONAL, Materials Park, OH, 1990.

U. Klement, U. Erb, A.M. El-Sherik, and K.T. Aust: Mater. Sci. Eng. A, 1995, vol. 203, pp. 177–86.

R. Juza and W. Sachsze: Z. Anorg. Chem., 1943, vol. 251, p. 201.

L. Maya, T. Thundat, J.R. Thompson, and R.J. Stevenson: Appl. Phys. Lett., 1995, vol. 67, pp. 3034–36.

C.S. Smith: Trans. AIME, 1948, vol. 175, pp. 15–51.

Ö.N. Dogan, G.M. Michael, and H.W. Kwon: Metall. Trans. A, 1992, vol. 23, pp. 2121–29.

P.A. Beck, J.C. Kremer, L.J. Demer, and M.L. Holzworth: Trans. AIME, 1948, vol. 175, pp. 372–94.

J.E. Burke: Trans. AIME, 1949, vol. 180, pp. 73–91.

R.A. Vandermeer and H. Hu: Acta Metall. Mater., 1994, vol. 42, pp. 3071–75.

H.J. Frost and M.F. Ashby: Deformation-Mechanism Maps, Pergamon Press, Elmsford, NY, 1982, p. 21.

W. Dickenscheid, R. Birringer, H. Gleiter, O. Kanert, B. Michel, and B. Günther: Solid State Commun., 1991, vol. 79, pp. 683–86.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Lee, J., Zhou, F., Chung, K.H. et al. Grain growth of nanocrystalline Ni powders prepared by cryomilling. Metall Mater Trans A 32, 3109–3115 (2001). https://doi.org/10.1007/s11661-001-0185-8

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-001-0185-8