Abstract

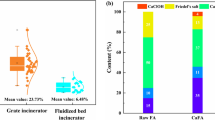

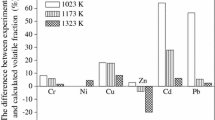

Municipal solid waste incineration (MSWI) fly ash constitutes a hazardous waste. Melting disposal has been verified to be prospective for stabilizing heavy metals and dioxins. Release of contaminant HCl during MSWI fly ash thermal treatment leads to potential environmental risks. The behavior and transformation of chlorine are critical to the disposal strategy of MSWI fly ash. In this study, the pathway of HCl formation in MSWI fly ash thermal treatment under complex atmosphere was revealed. Results show that CaOHCl in fly ash was first decomposed to CaCl2, CaO and H2O below 550°C, which provides H for HCl generation. Then, CaCl2, NaCl or KCl were reacted with H2O to release HCl, during which process H2O and O2 promote HCl formation, CO inhibit HCl production since H2O is consumed in water-gas reaction. The initial temperature of HCl generation affected by the concentration of H2O in the atmosphere. When temperature up to 1250°C, almost all NaCl or KCl were volatilized, HCl mainly from the reaction of chlorine-containing minerals with H2O, such as Ca19.2Mg2.8(Si0.75Al0.75)8 O36Cl2, Ca4(SiO4)(SO4)Cl2 and Ca10(SiO4)3Cl2 in N2, CO and air atmosphere separately. Moreover, in a reducing atmosphere, metals are more easily chlorinated by HCl, resulting in further consumption of HCl. The order of atmosphere for reducing HCl emissions should be CO>N2>Air>>H2O.

Similar content being viewed by others

References

Ma W.C., Wenga T., Frandsen F.J., The fate of chlorine during MSW incineration: Vaporization, transformation, deposition, corrosion and remedies. Progress in Energy and Combustion Science, 2020, 76: 100789.

Wang B.M., Fan C.C., Hydration behavior and immobilization mechanism of MgO−SiO2−H2O cementitious system blended with MSWI fly ash. Chemosphere, 2020, 250: 126269.

National Development and Reform Connission, On the issuance of the “facilities for the classification and treatment of urban household garbage” notice on the implementation plan for strengthening weak links, https://www.ndrc.gov.cn/xxgk/zcfb/tz/202008/t20200807_1235742.html.

Zhang J.J., Zhang S.G., Liu B., Degradation technologies and mechanisms of dioxins in municipal solid waste incineration fly ash: A review. Journal of Cleaner Production, 2020, 250: 119507.

Luo H., Cheng Y., He D., Review of leaching behavior of municipal solid waste incineration (MSWI) ash. Science of The Total Environment, 2019, 668: 90–103.

Zhu F.F., Takaoka M., Chang C.C., Chlorides removal for recycling fly ash from municipal solid waste incinerator. 2016: 358–373.

Abe S.-i., Kambayashi F., Okada M., Ash melting treatment by rotating type surface melting furnace. Waste Management, 1996, 16(5): 431–443.

Gan M., Wong G.J., Fan X.H., Enhancing the degradation of dioxins during the process of iron ore sintering co-disposing municipal solid waste incineration fly ash. Journal of Cleaner Production, 2020: 125286.

Geng C., Liu J.G., Wu S.C., Novel method for comprehensive utilization of MSWI fly ash through co-reduction with red mud to prepare crude alloy and cleaned slag. Journal of Hazardous Materials, 2020, 384: 121315.

Gao J., Dong C.Q., Zhao Y., Vitrification of municipal solid waste incineration fly ash with B2O3 as a fluxing agent. Waste Management, 2020, 102: 932–938.

Wey M.Y., Chen J.C., Wu H.Y., Formations and controls of HCl and PAHs by different additives during waste incineration. Fuel, 2006, 85(5): 755–763.

Belevi H., Moench H., Factors determining the element behavior in municipal solid waste incinerators. 1. Field studies. Environmental Science and Technology, 2000, 34(12): 2501–2506.

Du S.L., Wang X.H., Shao J.A., Releasing behavior of chlorine and fluorine during agricultural waste pyrolysis. Energy, 2014, 74: 295–300.

Nielsen H.P., Baxter L.L., Sclippab G., Deposition of potassium salts on heat transfer surfaces in straw-fired boilers: a pilot-scale study. Fuel, 2000, 79(2): 131–139.

Liu D., Li W., Li S., Transformation characteristics of sodium, chlorine and sulfur of Zhundong coal during O2/CO2 combustion in circulating fluidized bed. Energy, 2019, 185: 254–261.

Hase T., Uddin M.A., Kato Y., Drying and organic chlorine thermal decomposition behavior of municipal solid waste using superheated steam. Journal of the Japan Society of Material Cycles, 2014, 25(1): 16–24.

Zhu H.M., Jiang X.G., Yan J.H., TG-FTIR analysis of PVC thermal degradation and HCl removal. Journal of Analytical and Applied Pyrolysis, 2008, 82(1): 1–9.

Becidan M., Sørum L., Frandsen F., Corrosion in waste-fired boilers: A thermodynamic study. Fuel, 2009, 88(4): 595–604.

Mlonka-Mędrala A., Magdziarz A., Gajek M., Alkali metals association in biomass and their impact on ash melting behaviour. Fuel, 2020, 261: 116421.

Zhao K.X., Hu Y.Y., Tian Y.Y., Chlorine removal from MSWI fly ash by thermal treatment: Effects of iron/aluminum additives. Journal of Environmental Sciences, 2020, 88: 112–121.

Wang X.T., Jin B.S., Xu B., Melting characteristics during the vitrification of MSW incinerator fly ash by swirling melting treatment. Journal of Material Cycles and Waste Management, 2017, 19(1): 483–495.

Nishigaki M., Reflecting surface-melt furnace and utilization of the slag. Waste Management, 1996, 16(5): 445–452.

Chen M.Z., Meng Y.D., Shi J.B., DC Arc plasma furnace melting of waste incinerator fly ash. Plasma Science and Technology, 2009, 11(1): 62–65.

Keisuke Nakahara M.T., Hiroshi Yamamoto, Takuya Shinagawa, Tetsuo Akashi and Minoru Tsurui Heavy metals recovery system for dust from NKK electric-resistance Furnace. NKK Technical Review, 2011, 84: 8–15.

Ma W.C., Fang Y.H., Chen D.M., Volatilization and leaching behavior of heavy metals in MSW incineration fly ash in a DC arc plasma furnace. Fuel, 2017, 210: 145–153.

Okada T., Tomikawa H., Efficiencies of metal separation and recovery in ash-melting of municipal solid waste under non-oxidative atmospheres with different reducing abilities. Journal of Environmental Management, 2016, 166: 147–155.

Yang G.Y., Ren Q.Q., Xu J., Co-melting properties and mineral transformation behavior of mixtures by MSWI fly ash and coal ash. Journal of the Energy Institute, 2021, 96: 148–157.

Huang Q.-X., Wang F., Zhang H.-D., In-situ CO measurement of gas and oil combustion flame using near infrared tunable diode laser with direct and modulated absorption signals. Optics Communications, 2013, 306: 99–105.

Lackner M., Tunable diode laser absorption spectroscopy (tdlas) in the process industries–A review. Reviews in Chemical Engineering, 2007, 23(2): 65–147.

Japanese Industrial Standards Committee, Methods test chlorideion content hardened concrete, JIS A 1154.

Liu J.Y., Zhuo Z.X., Xie W.M., Interaction effects of chlorine and phosphorus on thermochemical behaviors of heavy metals during incineration of sulfur-rich textile dyeing sludge. Chemical Engineering Journal, 2018, 351: 897–911.

Knudsen J.N., Jensen P.A., Dam-Johansen K. Transformation and release to the gas phase of Cl, K, and S during combustion of annual biomass. Energy & Fuels, 2004, 18(5): 1385–1399.

Wei X., Schnell U., Hein K.R.G. Behaviour of gaseous chlorine and alkali metals during biomass thermal utilisation. Fuel, 2005, 84(7–8): 841–848.

Wan K.D., Wang Z.H., Xia J., Numerical study of HCl and SO2 impact on potassium emissions in pulverized-biomass combustion. Fuel Processing Technology, 2019, 193: 19–30.

Di W.K., Wang Z.H., Xia J., Numerical study of HCl and SO2 impact on sodium emissions in pulverized-coal flames. Fuel, 2019, 250: 315–326.

Fraissler G., Jöller M., Brunner T., Influence of dry and humid gaseous atmosphere on the thermal decomposition of calcium chloride and its impact on the remove of heavy metals by chlorination. Chemical Engineering and Processing: Process Intensification, 2009, 48(1): 380–388.

Partanen J., Backman P., Backman R., Absorption of HCl by limestone in hot flue gases. Part II: importance of calcium hydroxychloride. Fuel, 2005, 84(12): 1674–1684.

Atkinson H.H. Handbook of Chemistry and Physics. Zeitschrift Für Physikalische Chemie, 1963, 14(11): 308–308.

Haynes W.M., CRC handbook of chemistry and physics. 2012.

Bin Q.X., Study on sagging and fouling characteristics of high-alkali low-rank coal during thermochemical conversion process. 2018, University of Chinese Academy of Sciences.

Wang X., Xie H., Du R., High-temperature chlorination of PbO and CdO induced by interaction with NaCl and Si/Al matrix. 2018, 8(60): 34449–34458.

Cai G.S., Quan H.H., Chemical technology of coal. 2012: Chemical Industry press.

Kurashima K., Matsuda K., Kumagai S., A combined kinetic and thermodynamic approach for interpreting the complex interactions during chloride volatilization of heavy metals in municipal solid waste fly ash. Waste Management, 2019, 87: 204–217.

Yu J., Sun L.S., Ma C.A., Mechanism on heavy metals vaporization from municipal solid waste fly ash by MgCl2·6H2O. Waste Management, 2016, 49: 124–130.

Nowak B., Frías Rocha S., Aschenbrenner P., Heavy metal removal from MSW fly ash by means of chlorination and thermal treatment: Influence of the chloride type. Chemical Engineering Journal, 2012, 179: 178–185.

Kurashima K., Kumagai S., Kameda T., Heavy metal removal from municipal solid waste fly ash through chloride volatilization using poly(vinyl chloride) as chlorinating agent. Journal of Material Cycles and Waste Management, 2020.

Zhang Y., Ren Q., Deng H., Fusibility characteristic and flow properties of semi-char from industrial circulating fluidized bed gasification. Fuel, 2018, 234: 904–913.

Acknowledgment

This work was financially supported by the National Natural Science Foundation of China (U1810127) and the Youth Innovation Promotion Association, Chinese Academy of Science (Y201932).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Yang, G., Ren, Q., Zhou, L. et al. Effect of Atmosphere on HCl Releasement during MSWI Fly Ash Thermal Treatment. J. Therm. Sci. 32, 2243–2255 (2023). https://doi.org/10.1007/s11630-023-1789-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11630-023-1789-8